Theme

Digital Transformation

Green Transformation

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The jaw boring rings (JB-type)(JB12) is suitable for CNC lathe.

For adjust the high accuracy of chuck during cutting performance.

For detailed specification and operation process, please download PDF.

GREEN ECO PRO CO. LTD.

Product Description :

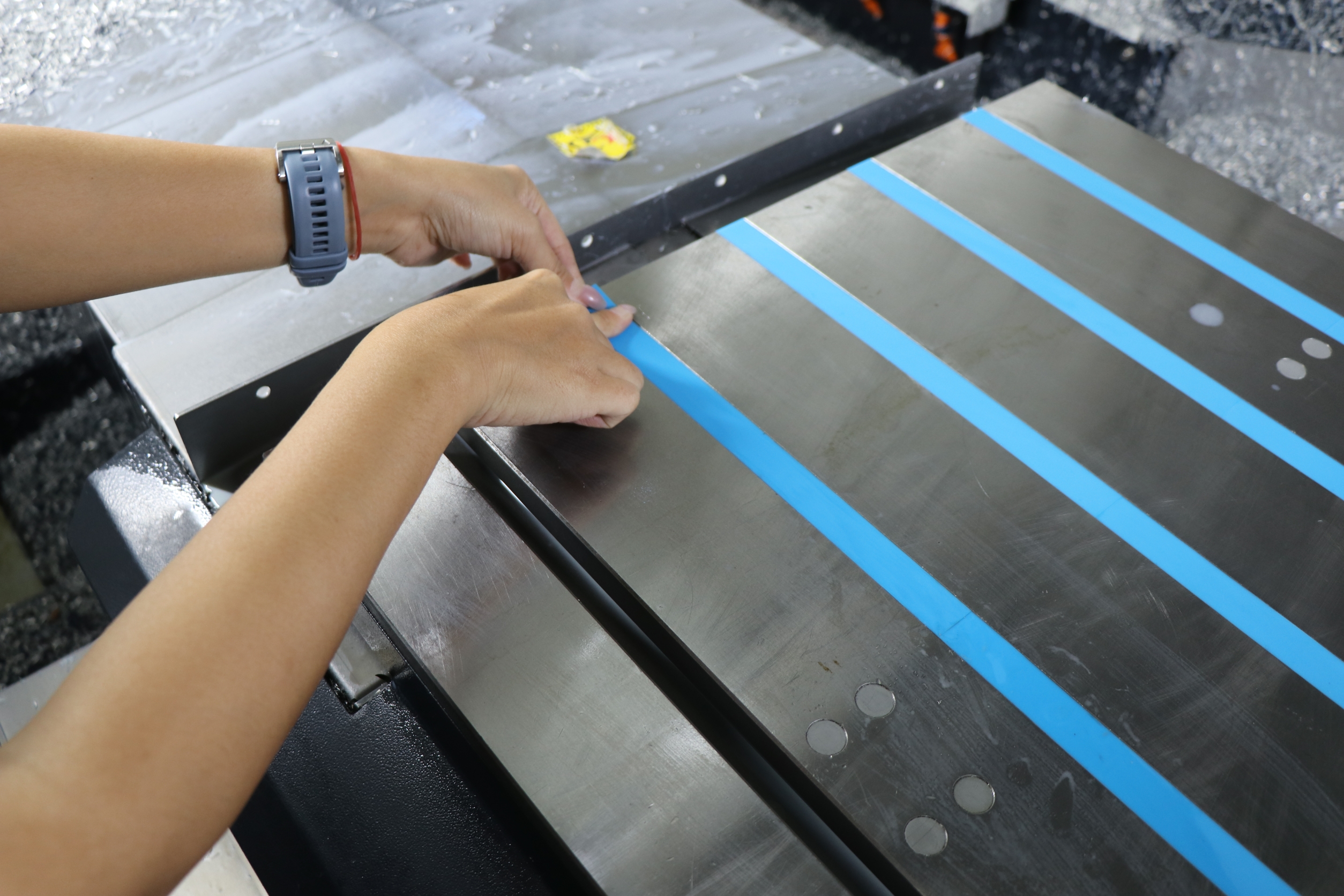

T- slot

The T-slot chip guard is developed to reduce your maintenance time cleaning your machine and changing your work-holding devices. They prevent chips and swarf from filling the T-grooves, which has always been a problem. It is not easy to wash away trapped chips with a coolant wash-down the gun or an air gun. The material is high-temperature resistant, flexible, and washable. In addition, it is extremely durable for dry machining applications. Overall, they look great and the kit is very affordable/cost-effective.

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

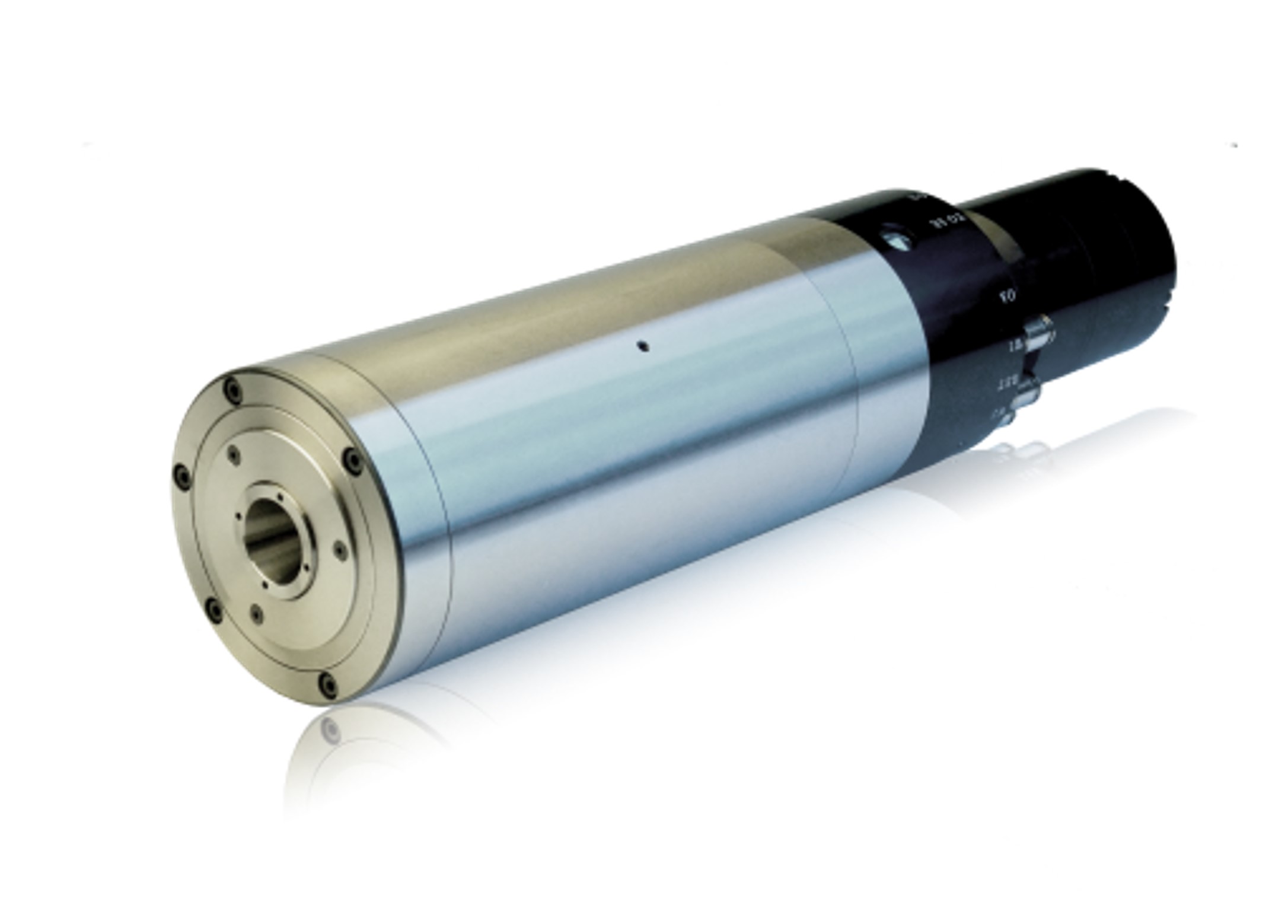

Spindle housing diameter : 170mm

Tool interface : HSK-A63

Maximum speed (rpm) : 24,000 RPM

Lubrication : Oil-Air

Motor power : 18/23 KW

GREEN ECO PRO CO. LTD.

Product Description :

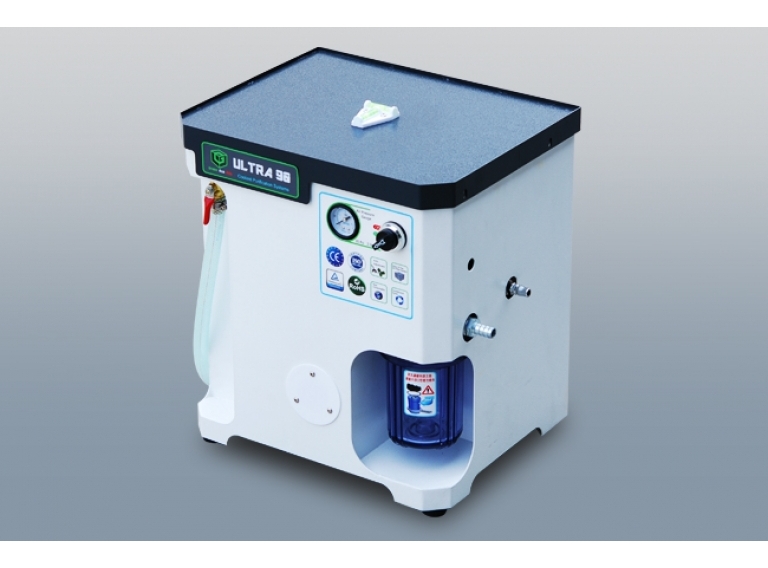

Oil Mist Collectors

Smart Alert Flagship Series

When the high-speed processing material that produce heat, and then heat to steam out the water, if the coolant tank of waste oil or other oil without correct handle, this time Processing heat will produce oil mist.

With one integrated mechanical design aesthetics

High efficacy with Mini Size

Low Decibel 65 db

Vibration rate G2.5mm/s

Unique development 2D turbine Wheel

Recycle oil above 99%

Intelligent Alert

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Brand new upgrade! Introducing the Grip Force Sensor (GFS-100) with advanced gripping technology. Bluetooth 5.0 ensures exceptional wireless connectivity, making your operations smoother. Convenient Type-C charging interface for easy charging, providing continuous power for your work. The high-performance lithium battery offers extended battery life, eliminating concerns about power shortage during work and allowing you to focus on your tasks. GFS-100 supports both Android and iOS systems, ensuring seamless compatibility for a user-friendly experience. With the flexibility to configure as a 2-claw or 3-claw operation based on your actual needs, it provides greater operational versatility. Upgrade your work experience with GFS-100, showcasing the convenience and efficiency of cutting-edge technology.

GREEN ECO PRO CO. LTD.

Product Description :

concentration on basic, To reduce floating oil on surface and prevent anaerobic bacteria and acidification of coolant. Solve the foul smell、Keep stable PH value、Save cost.

Oil reservoir capacity

Zero supplies

Patented technology - SKIMMER

Patented technology - S.T.P.M

Processing cycle

Small volume

Zero Power Consumption

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

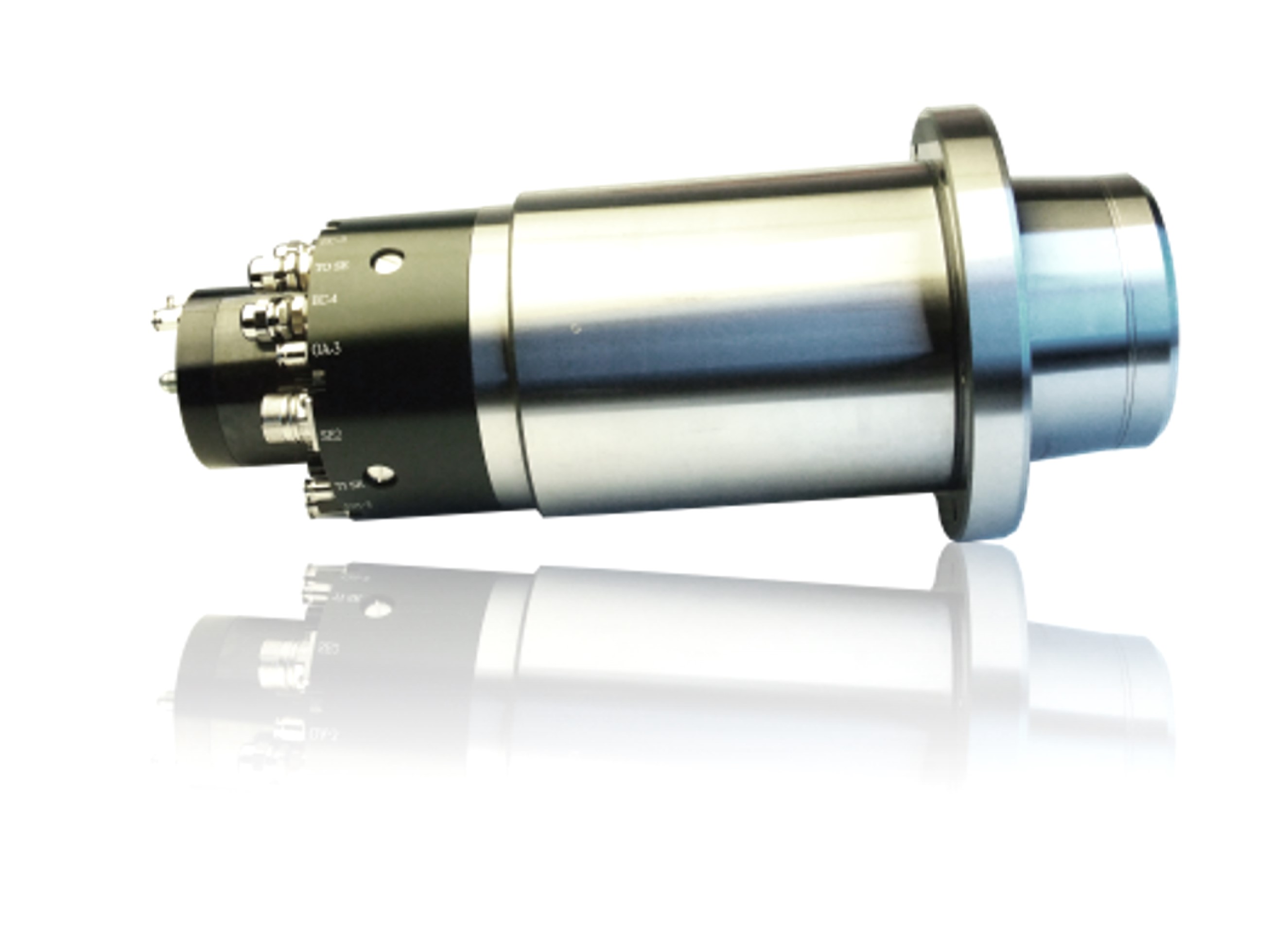

Spindle housing diameter : 100mm

Tool interface : HSK-E32

Maximum speed (rpm) : 30,000 RPM

Lubrication : Grease

Motor power : 3.5/5.5 Kw

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

HOMGE MACHINERY IND. CO., LTD.

Product Description :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.