Theme

Digital Transformation

Green Transformation

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The aluminum round jaws(FW-A10050) are suitable for extra bigger outer dia. (thin pipe.).

This type of round jaws can cover the outer dia. of work piece enable to decrease deformation and increase the accuracy.

For example: Type of FW08 can hold parts with outer dia. of 200mm.

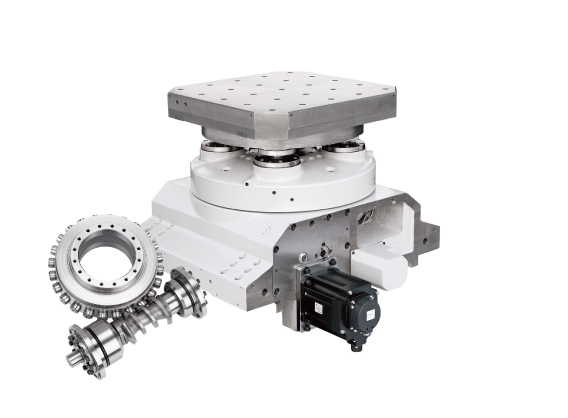

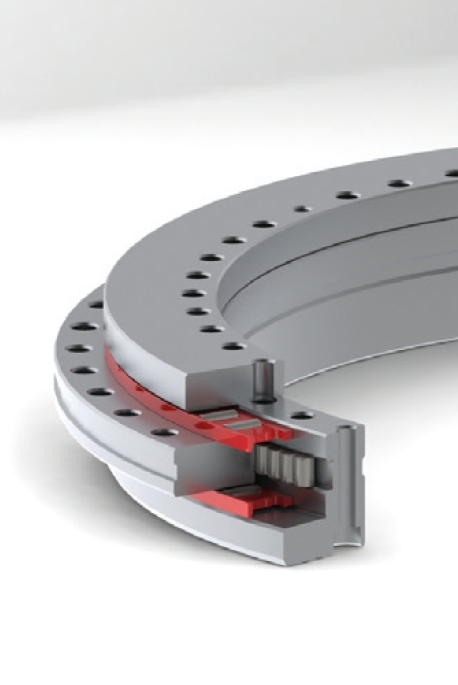

Go power machinery CO.LTD

Product Description :

Gutian Cam NC Rotary Table internally adopts cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy, without theneed for periodic calibration and adjustments. This product is featured with high rigidity,heavy load, high efficiency, and its accuracy is not affected by rising temperature.

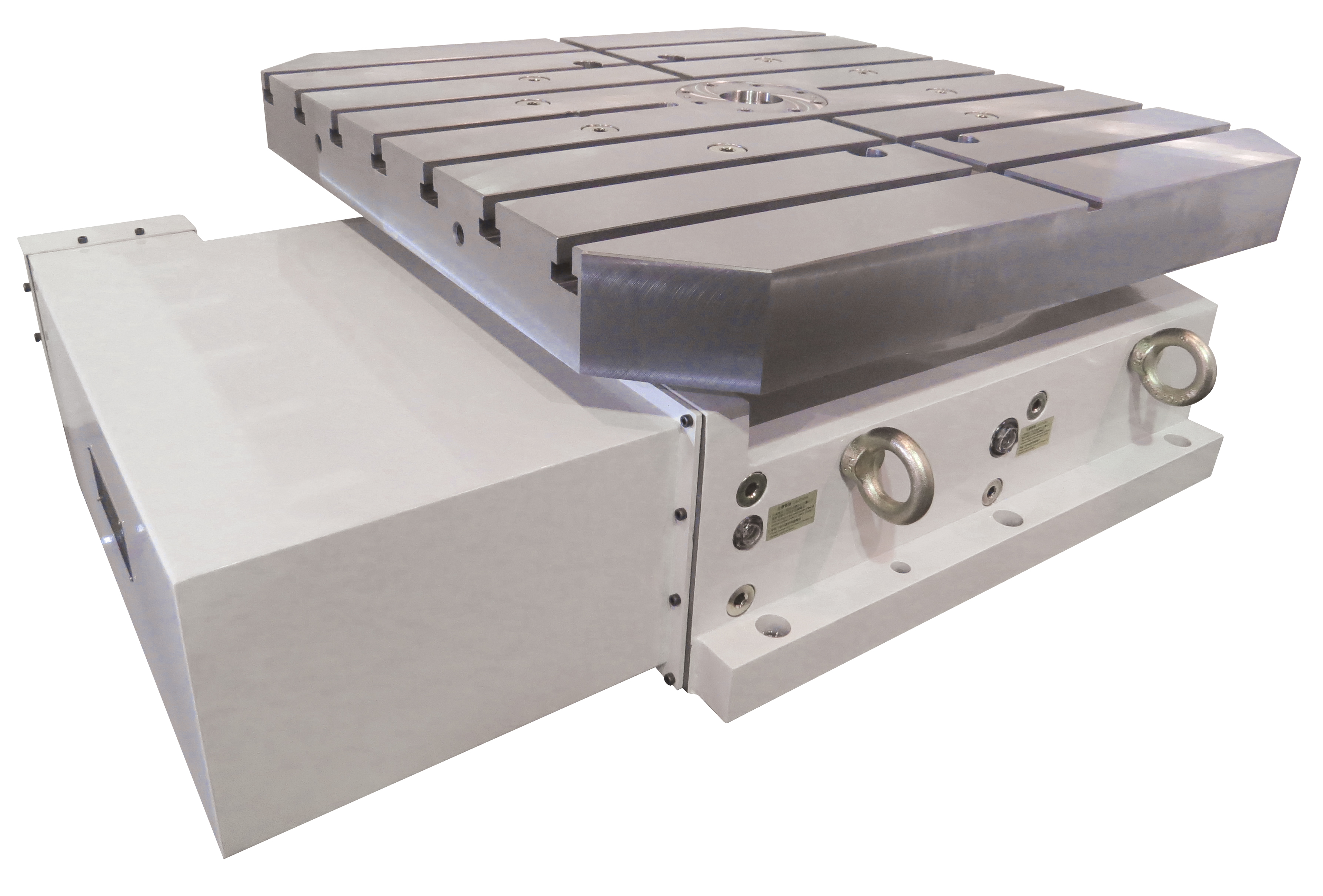

GSA TECHNOLOGY CO., LTD.

Product Description :

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。

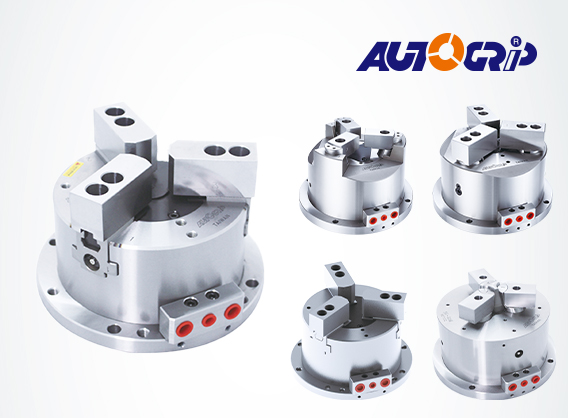

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

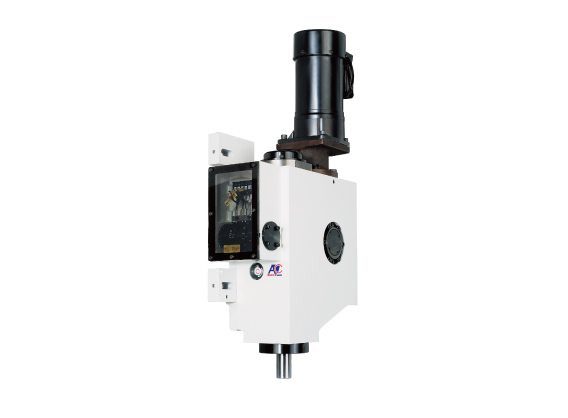

SAFEWAY MACHINERY INDUSTRY CORPORATION

Product Description :

1. Large through hole design.

2. Drive by dual-lead worm. Exceptional high-tensile brass.

3. Disc brake capacity.: Maintain high torque for consistent usage.

4. Crossed Roller Bearing : High Rigidity.

5. Brake signal : 2 pieces of pressure switch ( made in Germany )

6. Solenoid Vales ; SMC ( made in Japan )

7. Copper worm gear : Made in Japan .

8. Highest quality of all components .

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

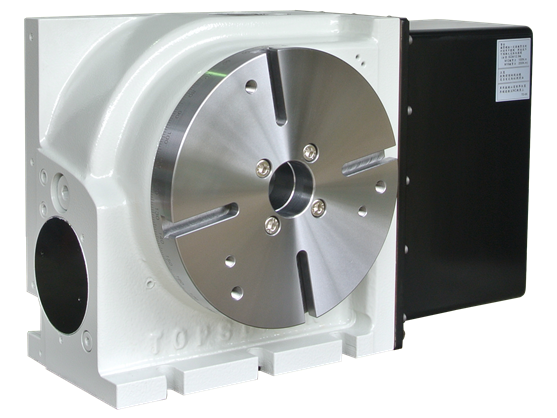

GSA TECHNOLOGY CO., LTD.

Product Description :

Dual lead worm wheel / worm shaft which allowable easy backlash adjustment。

Double bearing design suitable for heavy cutting。

One piece of faceplate and spindle design which offer rigid construction。

Large thru hole design which allowable large work piece going thru spindle。