Theme

Digital Transformation

Green Transformation

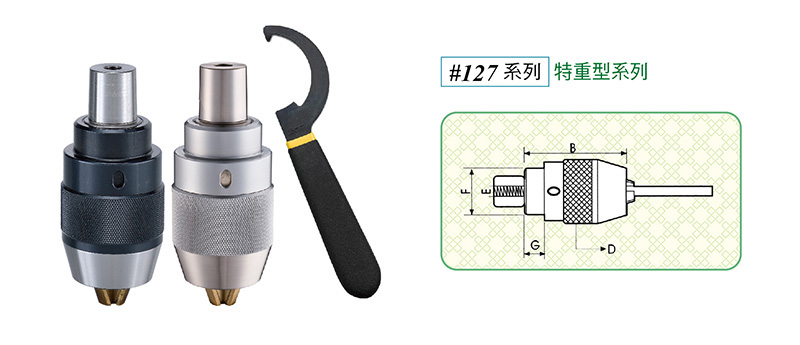

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

TOOL SHANK TYPE

Multi-choices of mounting specification offers quick changeover on machining center

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

Hole deflection within 0.004

■Choose Machine : Star SR-20RIV SR-32J

■Detailed specifications

△Speed ratio :1:1

△Maximum speed : 6000RPM

△Tool clamping : ER16M/ER11M

△Reference code :0M155

https://www.songgia.com.tw/en/products/3-spindle-double-drilling-milling-unit-stra2b3201

YINSH PRECISION INDUSTRIAL CO., LTD.

Product Description :

The YS series precision bearing locknuts combine four common locking methods and are especially suitable for various types of machine tools for high-speed operations with high precision and high efficiency.

TJR PRECISION TECHNOLOGY CO., LTD.

Product Description :

① Almost no backlash during the clockwise/anti-clockwise rotation

② Almost no abrasion for the transmission mechanism

③ High speed

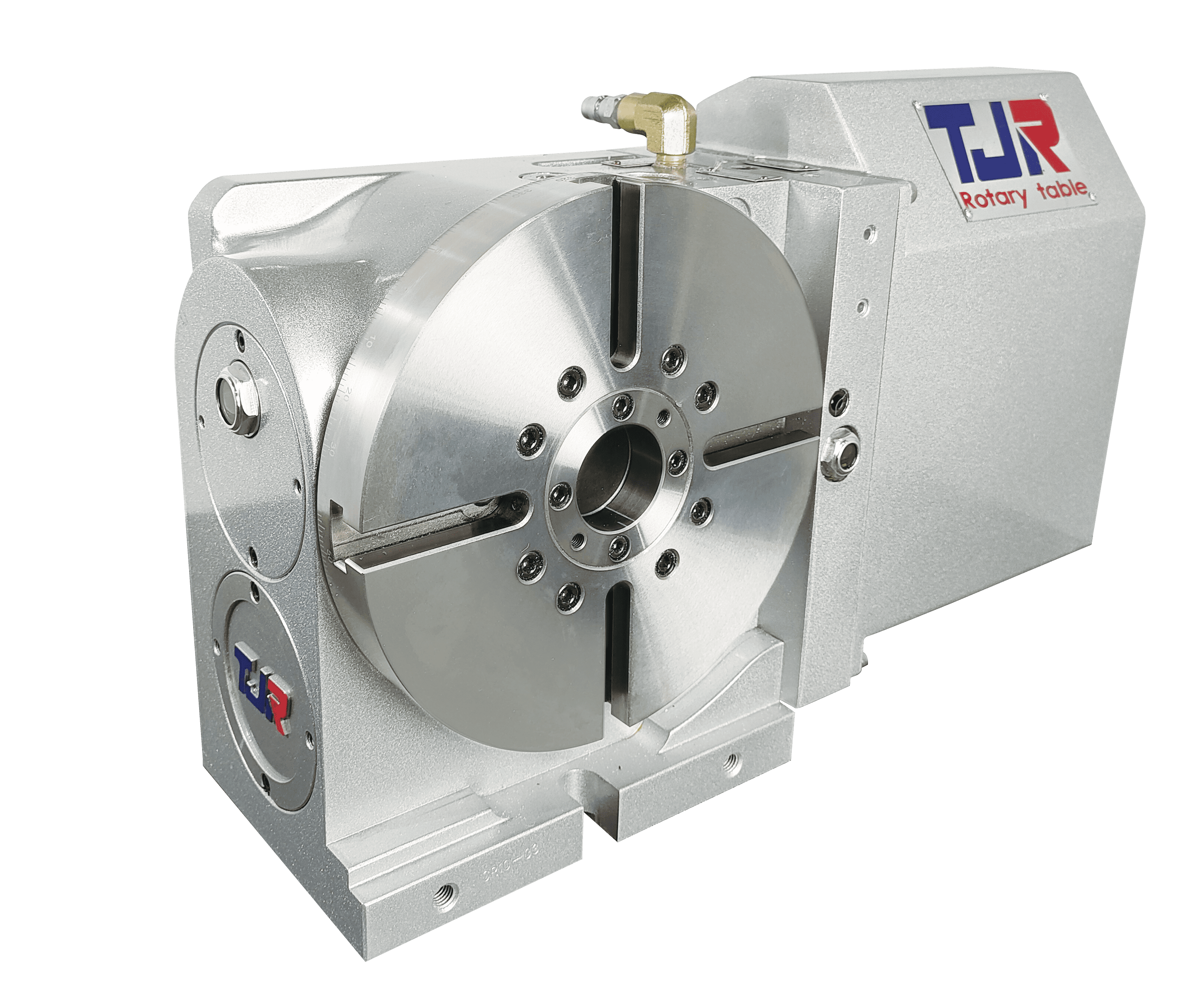

TJR PRECISION TECHNOLOGY CO., LTD.

Product Description :

① Driven by D.D.M.

② No backlash, no wear

③ High-speed 200rpm

④ Oil cooling and auto self-locking system

⑤ Can be customized according to the requirement of the machine tool factory

HSU PEN INTERNATIONAL PRECISION MACHINERY CO., LTD.

Product Description :

*Employs high rigidity, extra large radial and axial bearing.

*For models over 255, the tilting axis employs the latest full circumference brake, featuring even braking force without runout. Maximum clamping area, higher clamping force, no vibration and no braking delay is required. High torque combined with compact, rigid and enclosed structure ensure high cutting quality.

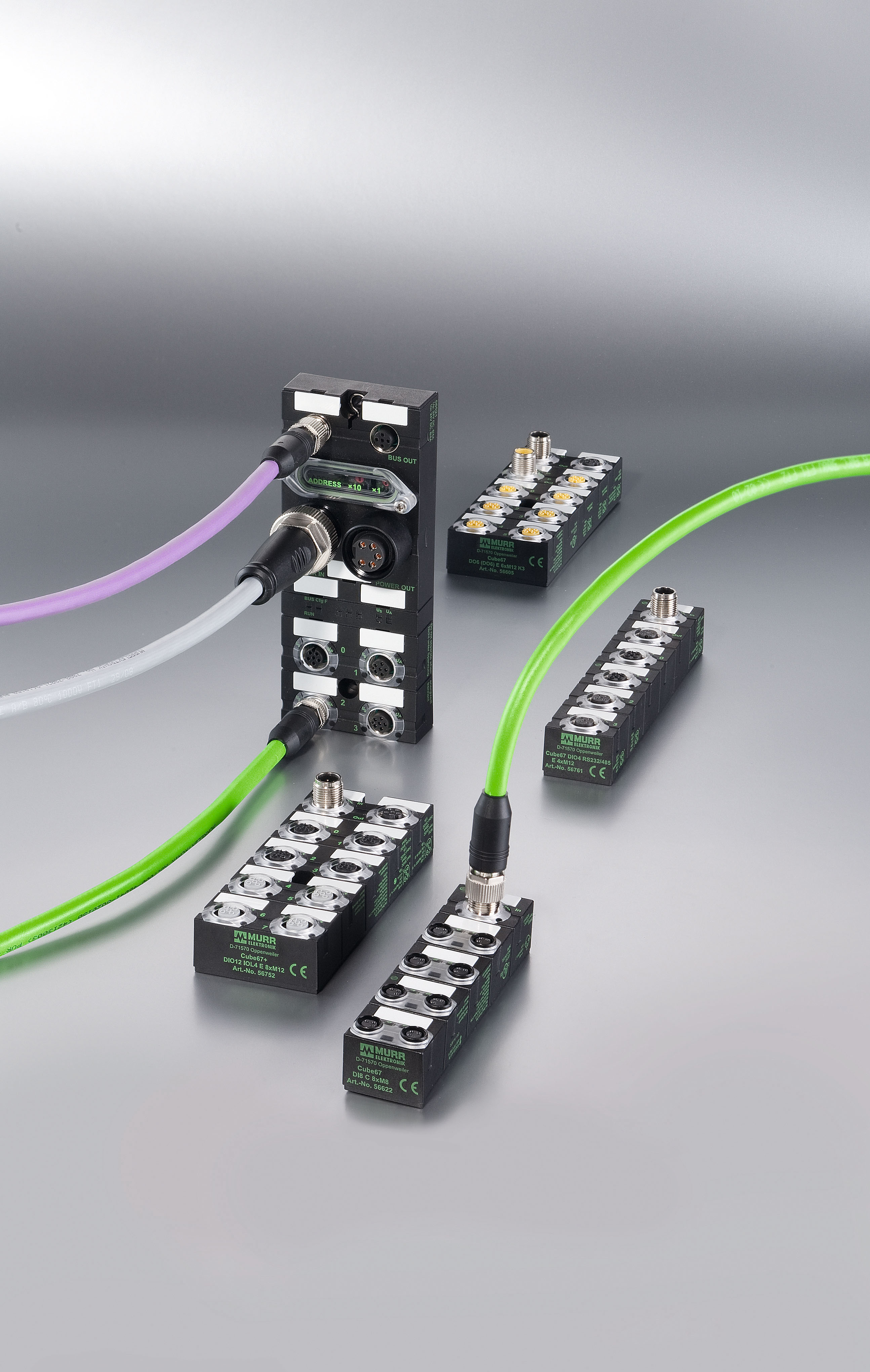

LINTRONIX CO., LTD.

Product Description :

德國 Murrelektronik的策略

•減少控制箱空間:採用遠端IO 與IP67Ethernet switch

•即插即用可配置I / O系統

•使用Cube67+複合電纜技術降低佈線

•全面的診斷=輕鬆調校,並減少停機時間

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Spindle Motor:Permanent Magnet Synchronous Motor22W(30HP)

◎Max. Diameter of Cutter:Ø300

◎Feed Travel:500mm

◎Speed Change Method:Manual/12 Section

FUTECH PRECISION CO.,LTD.

Product Description :

Wedged 3-jaws type of hook with large through hole.

Hardened, ground and directly lubricated matching surfaces of all parts.

Construction of high rigidity, and high accuracy of clamping.

GSA TECHNOLOGY CO., LTD.

Product Description :

All Series Use 3 Pieces Hirth Coupling & Hydraulic Clamp / unclamp System Suitable For Heavy Turning Long Term Operation。

Driving Source Per Servo Motor/Drive To Turing Tool Disc,High Indexing Accuracy。

Accepted OEM/ODM Orders。

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.