Theme

Digital Transformation

Green Transformation

Go power machinery CO.LTD

Product Description :

Gutian horizontal cam fix-axis rotary table has internal cam roller transmission mechanism.

There is backlash-free rolling drive between cam and needle bearings pre-load, no sliding

friction or backlash. Its positive reverse motion has high repeatability accuracy without the

need for periodic calibration and adjustment. Its accuracy is not affected by rising

temperature. Improving the quality of multi-axis machining parts can greatly reduce defective

rate of machined parts.

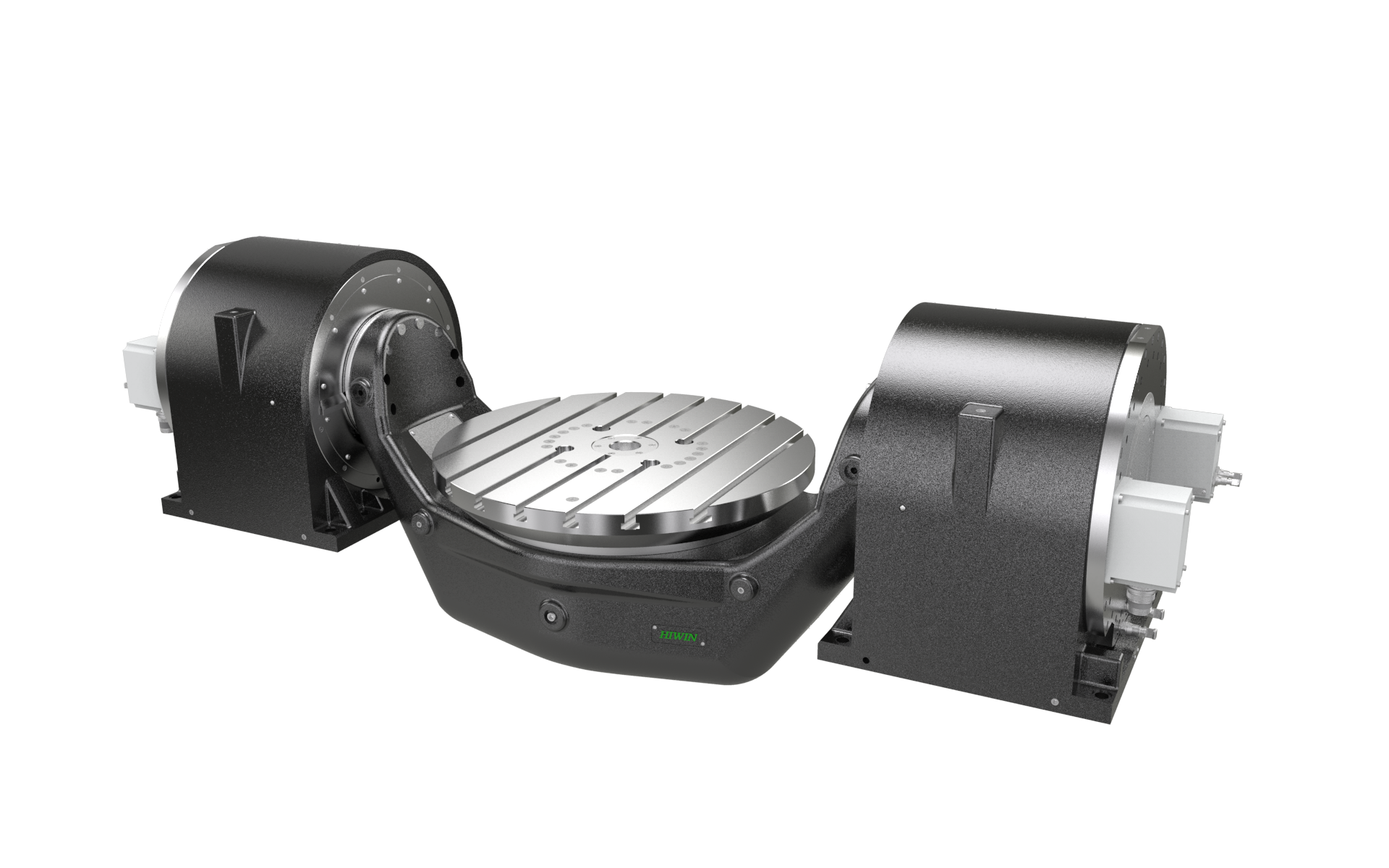

HIWIN TECHNOLOGIES CORPORATION

Product Description :

HIWIN Torque Motor Rotary table equips with HIWIN’s water cooled direct drive motor. With features of high torque, high precision and zero backlash including crossed roller bearings and pneumatic braking system, which plays an important role in the multi-axis machines. These rotary tables can increase the competitiveness of the machines with high speed, high performance, high precision and one time machining program reducing the errors during disassembly and clamping of components between multiple machines to complete the machining task, achieve the ability for complicate curve machining in one setup.

① The underwater rotary table (RCV-E series), lightweight insulation, up to IP 68 -rated waterproof and dustproof, suitable for discharge rotary cutting and grinding processing applications.

② Double axis rotary table (RAB/RAS Series)

Key component for high end multi axis machining center.

③ Single axis rotary table (RCV/RCH Series)

Widely used in turn-mill machining centers with speed up to 2,000 RPM.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

■Choose Machine : Tsugami S205/S206■Detailed specifications

▼Speed ratio :1:1▼Maximum speed : 5000RPM▼

▼Tool clamping : Utilis no.119287▼Angle adjustment : ±20°

▼Reference code : 3281-Y450

https://www.songgia.com.tw/en/products/thread-whirling-unit-tssa545201

SHARP ONE CO., LTD.

Product Description :

M26AB is of good quality and meets market needs. It solves the

incomplete design of the traditional end mill grinding machine on the

original market. Compared to other brands, M26AB features are as

follows.

Single piece grinding wheel can grind different end gash, first to none.

It can grind variable index and spiral.

Positioning is visible. Grinding intensive and powerful blades is

adjustable.

Grinding carbide flat drill bit.

Grinding chip flutes positive angles.

Standard vacuum can decrease chips spreading, good for health and

machine.

M26AB multi-function machine greatly reduces the cost of end mills

and increases the efficiency. It is the first end mill grinding machine with

standardized positioning, standardized & friendly operation, and multifunction

on the market. These advantages attract users to test our

machines and prove that M-26-AB can help their daily work.

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M48 to fulfill your demand

(M8 ※ 0.3t _ M64 ※ 12t)

2. Design Factor 4:1, Working load limit could be up to 32 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. 360 degrees rotation to avoid traditional eye bolt bending.

5. Light weight, High Performance, easily for using

Deliver with test certification to guarantee your safety

A Being Kou Tools Co., Ltd.

Product Description :

After becoming frustrated by the existing coolant hose products on the market; all of which suffered from a variety of shortcomings, Arnold Lockwood conceived the idea for the modular hose that became Loc-Line®. The shortcomings of the existing products included, metal coolant hoses that would not stay where they were positioned and plastic hoses with metal positioning rods that broke.

In 1981 Lockwood Products was formed to develop and distribute Loc-Line®. The first products were shipped in August of 1983.

Loc-Line® quickly became the standard for coolant delivery around the world and was easily recognized by our Blue and Orange colors and consistent high quality.

Today Loc-Line® is still the leader in modular hose and continues to innovate in the modular hose field. Loc-Line® is used not only as a coolant hose but for air delivery, smoke and dust removal vacuum systems, agriculture, third arm uses including positioning cameras, lights and items for handicap assist.

We here at Lockwood Products, Inc are proud to have originated the modular hose Loc-Line© that remains the standard for the industry worldwide!

Please visit one of our distributors today and see for yourself why Loc-Line remains the best and most versatile solution in the world today!

YOKE INDUSTRIAL CORP

Product Description :

•Rotates through 360° and pivot 180°, and simultaneously allows lifting from any direction.

•Manufactured from forged alloy steel, quenched and tempered.

•Manufactured and tested in accordance with EN1677-1.

•Load rated parts are 100% magnaflux crack detected.

•Individual forged parts and cap screw are traceable to Test Certification.

•Bolt are Metric thread (ASME / ANSI B18.3.1M).

•Proof tested to 2.5 times the WLL.

•Fatigue rated to 1.5 times the WLL.

•All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

•Quick and simple assembly, just a tapped hole is required.