Theme

Digital Transformation

Green Transformation

Tokai Spring industries, Inc.

Product Description :

Tokai spring is committed to manufacturing small-lot and custom-made spring orders because we believe that there are customers who need highly specialized, high quality spring products. Tokai spring’s mission is satisfying or even exceeding our customer’s requirements.

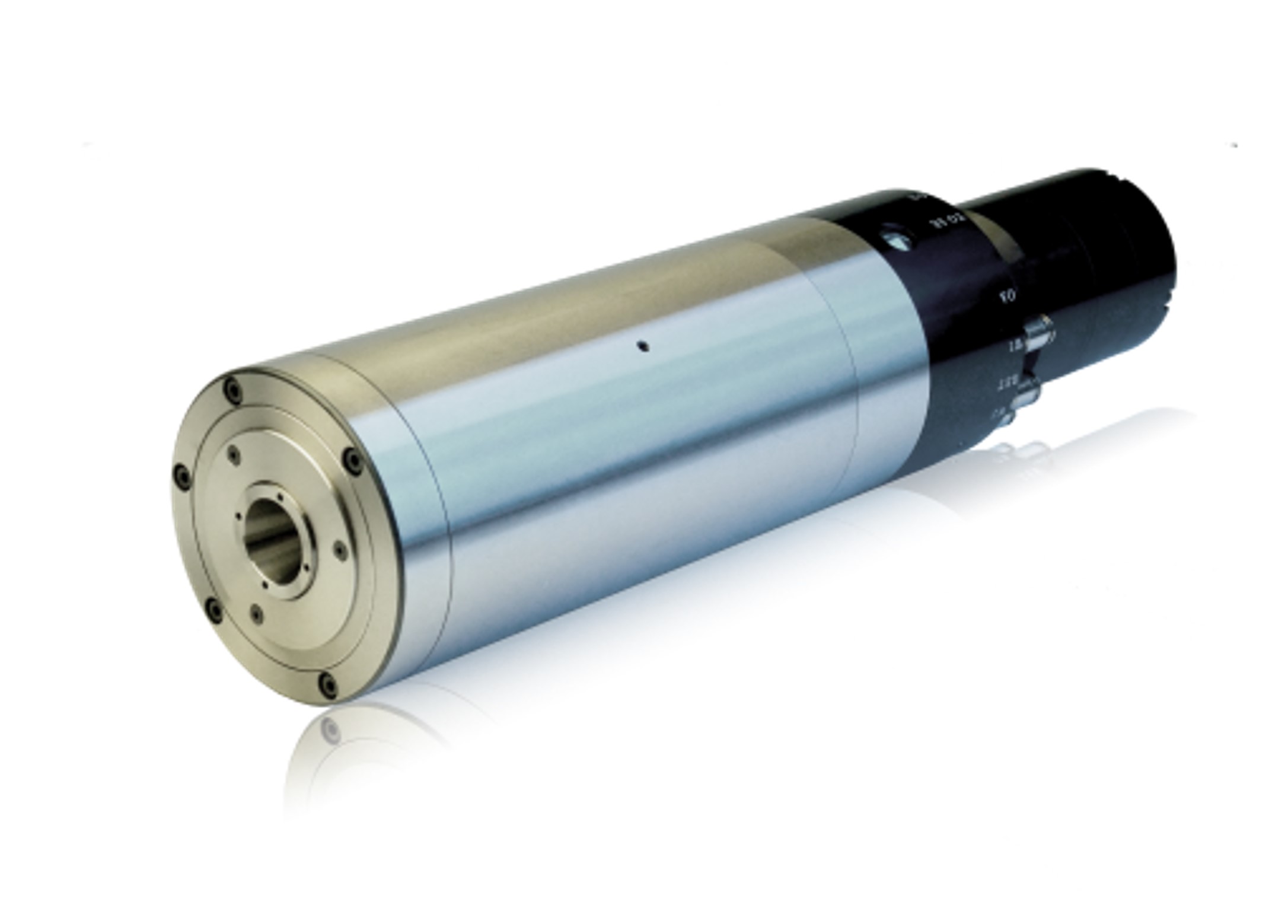

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

Hole deflection within 0.004

■Choose Machine : Star SR-20RIV SR-32J

■Detailed specifications

△Speed ratio :1:1

△Maximum speed : 6000RPM

△Tool clamping : ER16M/ER11M

△Reference code :0M155

https://www.songgia.com.tw/en/products/3-spindle-double-drilling-milling-unit-stra2b3201

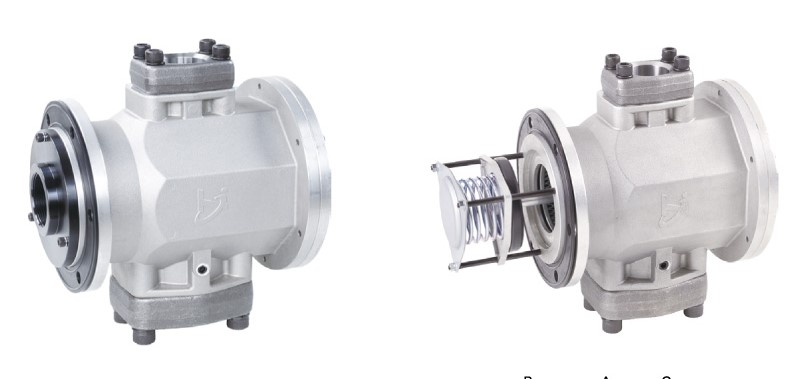

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

In order to solve the problem of difficult cleaning, the market developed so-called box-shaped filters, but still can not completely solve

1 takes up too much space

2 Multiple pump combination systems must be configured one-to-one, resulting in too many connectorsProne to oil leakage

In order to solve the above problems, the company has developed a pair of two-box external magnetic flange filters to reduce space and prevent oil leakage problems, reduce assembly time and parts costs

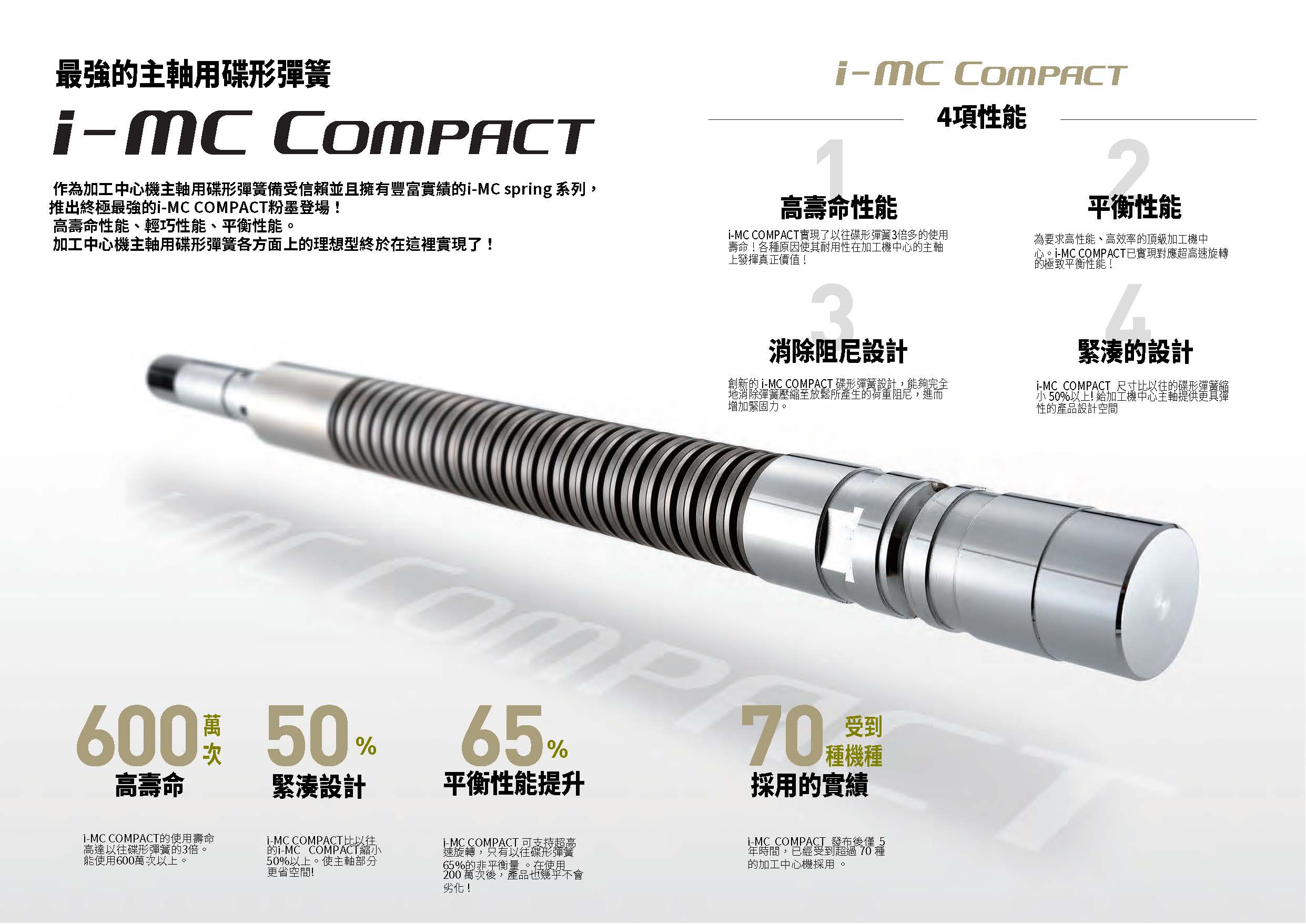

Tokai Spring industries, Inc.

Product Description :

i-MC spring series has established a strong trust and reputation as disc springs for the main spindle on machining centers among manufacturers. i-MC COMPACT is a new and innovative product of i-MC spring series.

Long-life performance, compact performance and balance performance.

In all of these aspects, this new product achieves the ideal form of disc springs for the main spindles on machining centers.

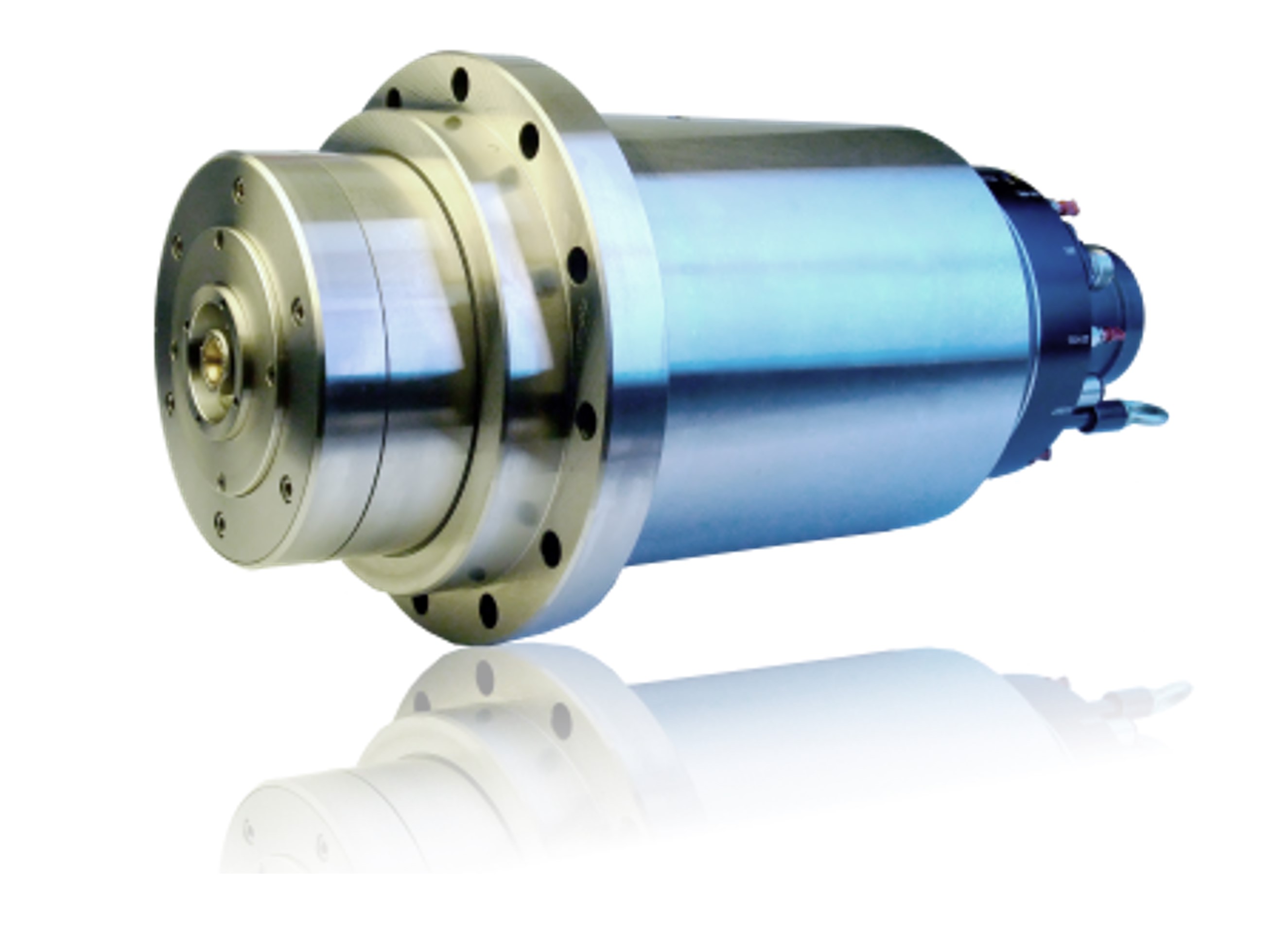

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

SHARP ONE CO., LTD.

Product Description :

M26AB is of good quality and meets market needs. It solves the

incomplete design of the traditional end mill grinding machine on the

original market. Compared to other brands, M26AB features are as

follows.

Single piece grinding wheel can grind different end gash, first to none.

It can grind variable index and spiral.

Positioning is visible. Grinding intensive and powerful blades is

adjustable.

Grinding carbide flat drill bit.

Grinding chip flutes positive angles.

Standard vacuum can decrease chips spreading, good for health and

machine.

M26AB multi-function machine greatly reduces the cost of end mills

and increases the efficiency. It is the first end mill grinding machine with

standardized positioning, standardized & friendly operation, and multifunction

on the market. These advantages attract users to test our

machines and prove that M-26-AB can help their daily work.