Theme

Digital Transformation

Green Transformation

TAIWAN FANUC CORPORATION

Product Description :

Lathe chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

TAIWAN FANUC CORPORATION

Product Description :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.

TAIWAN FANUC CORPORATION

Product Description :

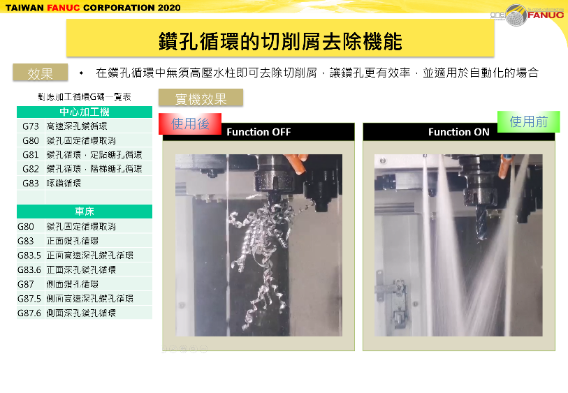

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

TNC7

Innovative | Sustainable | Reliable

Continuously developed, the new software version 18 of the TNC7 fulfills many requests from users and machine manufacturers about ease of operation, reliable processes and enhanced functions.

Discover intelligent functions with which the TNC7 can assist you in your future tasks!