Theme

Digital Transformation

Green Transformation

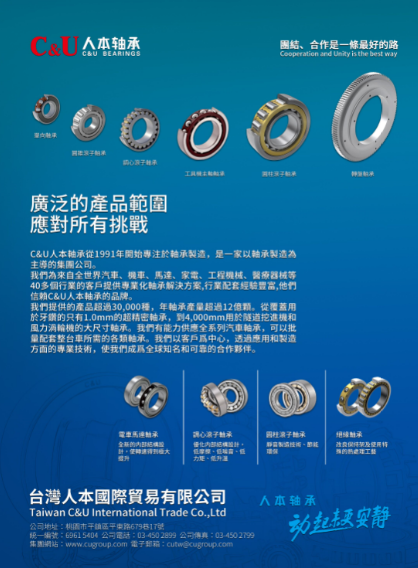

TAI WAN C&U INTERNATIONAL TRADE CO.,LTD.

Product Description :

軸承製造業是人本集團的主導產業,其生產的精密低噪音軸承是經國家軸承監督檢驗中心檢測,精度儲備率100%,優等品率100%,Z3組穩定達產率95%,Z4組穩定達率60%以上,在國內同行業處於領先地位,填補了國內空白。人本(C&U)軸承還多次獲中國“精品軸承”稱號。現已形成溫州、杭州、無錫、上海、南充、蕪湖和黃石等七大軸承生產基地,已擁有73家軸承成品和配件製造企業,下屬成員企業146家。集團能生產內徑1.0mm至4000mm範圍內的軸承三萬餘種,在國內同行業中產銷排名第一。

PRECISION MOTION INDUSTRIES, INC.

Product Description :

Achieved the high-precision motions, lifting, rotaty, as well as quick grip motion in confined spaces.

Features

•High Positioning Accuracy

•Lightweight and Compact

•Simple Installation

•Support Bearing

•Smooth Motion and Lower Noise

Application

SCARA robot, Assembly robot, Automatic loader, and Machining center's, ATC equipment.

HIWIN TECHNOLOGIES CORPORATION

Product Description :

【ESG Sustainable Goal for Motion Control Components】

According to TrendForce research, the green factories will boost the global smart manufacturing market, which will reach $620 billion by 2026. As the concept of ESG sustainability has set off a wave of enthusiasm around the world, HIWIN linear motion components have also continued to focus on intelligent energy-saving innovation, providing simple, safe and modular designs to help customers upgrade from the inside out and embrace the trend of ESG energy saving!

The world’s first Intelligent 4.0 Ballscrew i4.0BS®, together with Intelligent 4.0 Guideway i4.0GW® and Intelligent Single-Axis Robot provide users to monitor health conditions of multiple machines and allow users to plan the production and pre-schedule the maintenance. The function of improving productivity and reducing carbon emission is also in line with the ESG sustainable goal.

-i4.0BS® multi-function sensors design with algorithm, effectively monitor the status of the Ballscrew. The users can monitor machines' conditions anytime.

-i4.0GW® sensor can be mounted on the block according to customers' demand. The system is fully compatible with i4.0BS®.

-The intelligent single-axis robot iSR has a modular design to meet the users' needs in various fields.

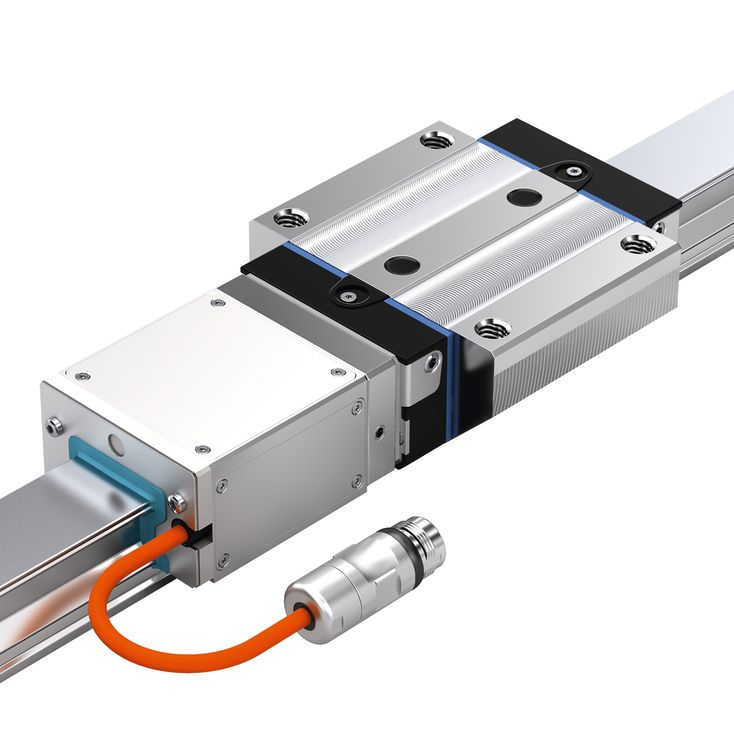

PRECISION MOTION INDUSTRIES, INC.

Product Description :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

JASON AUTOMATION CO., LTD.

Product Description :

Our linear components and systems are precisely developed and produced, and provide the basis for you to manufacture best-in-class machines and automation systems. The high quality and long life of our Linear Motion Technology guarantees you maximum system availability. With over 1000 standard components and products and our modular principle, we can always create an individual solution for you. As a leading user and supplier of Industry 4.0, we ensure that you are also ready for the future. We support our users reliably throughout the entire product life cycle, beginning with finding the right solution, to consulting and eTools, all the way to worldwide, on-site service.