Theme

Digital Transformation

Green Transformation

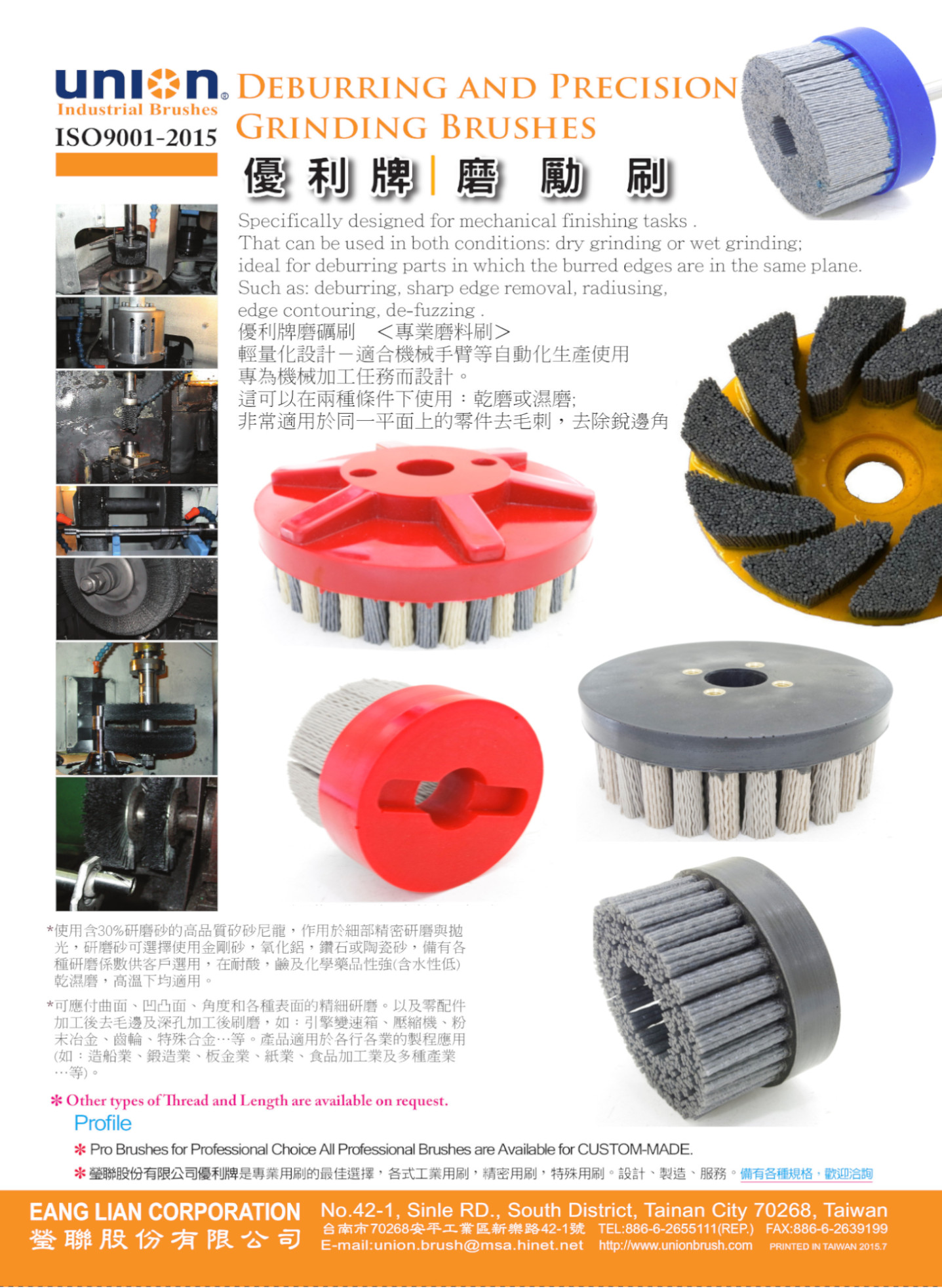

EANG LIAN CORPORATION

Product Description :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .

Giant Red-Wood Int’l & Co. Ltd

Product Description :

RW-600A Hydraulic Riveting Machine (Mitsubishi 10” HMI)

(Without Feeding System)

-Safety Device to protect finger get injured

-Proportional Value Control System

-Double-Pumps hydraulic Designed

-Auto-Riveted Counting to avoid missing riveted

-Mitsubishi 10” HMI

-Control System: Mitsubishi PLC

-Pressure Range:2-53KN(6T)

-Horsepower:3HP

-C type throat depth:450mm

-C types throat height:400mm

-Power Voltage:220V Three-Phase

*Mitsubishi 10” HMI can ensure the pressure during the operation. It also can auto-check for faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6 (Carbon Steel)

* Proportional Value Control System: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

*OMRON 5” HMI can ensure the pressure during the operation. It also can auto-check faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6( Carbon Steel)

*Pressure control easy to operate: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

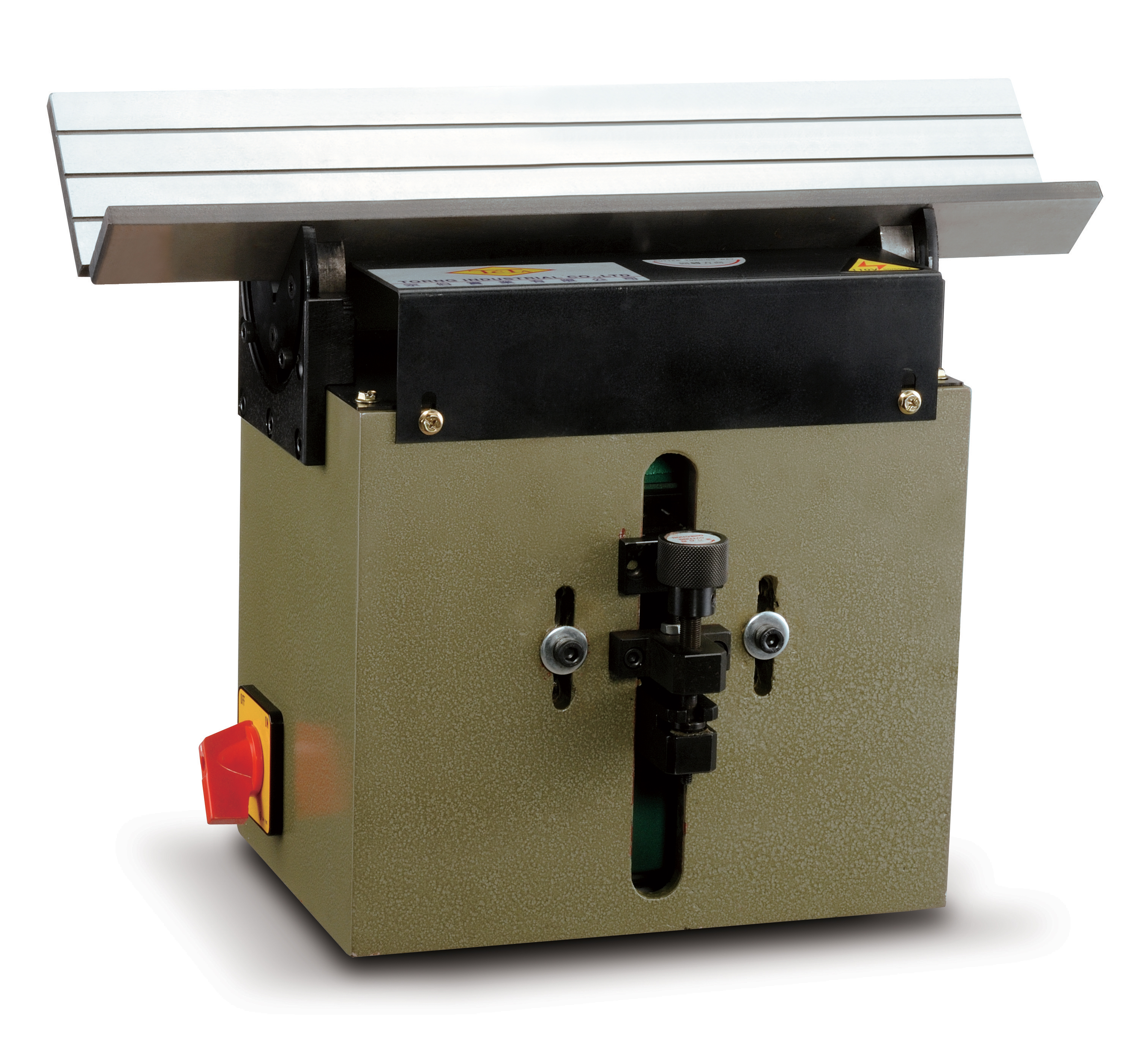

TORNG INDUSTRIAL CO., LTD.

Product Description :

* It adopts the principle of face milling, the chamfering method is like milling.

* Suitable for carbon steel,alloy steel,iron and aluminum.

* After chamfering, its surface is smoother than side cutter.

* Bevel angle : 45 degree.

* Angle can be adjusted.

JEFFER MACHINERY CO., LTD.

Product Description :

Automatic Tool Grinder JF-400 is developed to reduce labor time by allowing users to regrind their tools quickly and accurately, and is designed to ensure the highest grinding quality is achieved. JF-400, the Full carbide tool grinder, can be used to grind carbide cutter, router bits precisely.

Not only this auto Tool Grinder is featured the advantages of simple operation and has reliable performance at an affordable price.

JF-400 Feature :

This is a machine fully automatic controlled.

It is superior machine, which is easy to operate and can save manpower. Grinding just needs setting once.

★It could be used to grind carbide cutter, router bits and

finger jointer cutter very precisely.

It owns automatic feeding, withdraw and dividing.

1. Sharpen the face of solid cutter :

dia. 300x L250mm

2. Sharpen the router bits :

dia. 3-19mm

3. If buy the additional attachment of grinding finger

jointer cutter also can be shapered the finger jointer

cutters.

Grinding capacity: Finger jointer cutter:

dia.160mm/210mm/250mm;Bore: ◎50mm;Length of

finger joint cutter: 300mm

Option:

1.Setting device with arbor 50mm for finger joint cutter-

1set

2.V-typed tailstock-1pc -->for grinding finger joint cutter

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1.A circular tube modifies an interior angle and an external angle at one time with fastness and precision.

2. It's simple and fast to switch the knife because of easy to buy the insert disc in the market.

3. Two-stage of feeding knife, and the idle stroke is smooth. It's available for adjusting the operation stroke according to the cutting volume.

4. There are automatic and manual functions, which are convenient for adjusting the machine.

5. Special automatic positioning device, which can automatically position, feed and chamfer, and fine-tune the length tolerance.

6. Oil mist cooling and lubricating system promotes insert life, and no chips will stay.

7. There is a pause switch at the final point so as to assure the flat plane and the accurate right angle of the work piece.

8. The axle head with phosphor & copper bushing can prolong the life.

9. It can be option the lifting rack to use with this machine.