Theme

Digital Transformation

Green Transformation

CHEN SHIN (TCSM) MC CO., LTD.

Product Description :

Oil mist collector:

Totally made in Taiwan with TÜV CE marking.

Customisation Accessories ,Industry 4.0 Accessories and ODM/OEM Services are available.

Welcome for ODM/OEM cooperation.

We are Agent of SCOTTI in Taiwan market.

We are Agent of DUPLOMATIC in Taiwan market.

Electrical Oil Mist Collector

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The CT1-76YM is designed with a combination of double spindle and single turret.

■ ∅76mm enlarged spindle bore is ideal for turning large workpieces. ■ 16-positions power turret with Y-axis, it can complete machining on parts in the main or sub spindle. In addition, tools can be placed facing either the main or sub spindle.

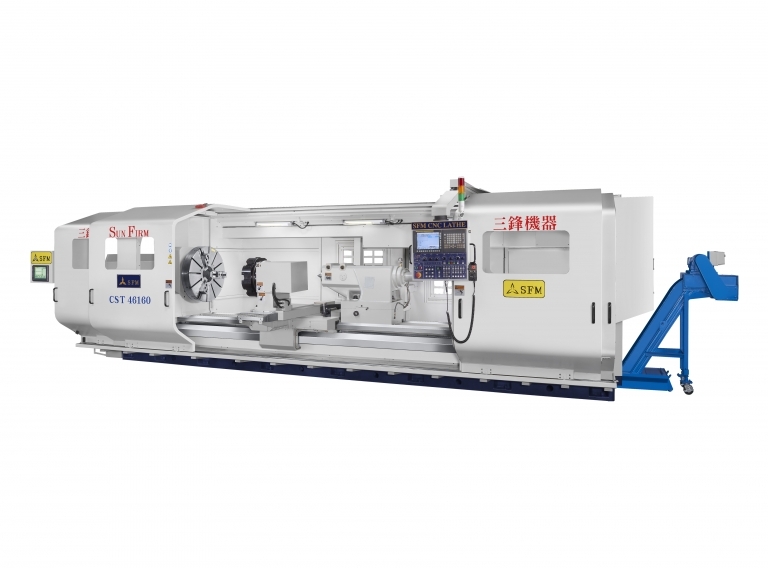

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The multi-function machine with B-axis can easy have bevel angle drilling and cutting work. The best torque is 3000Nm, and with curved coupling, it can easily do a heavy cutting job shop work and also curved surface milling. The machine uses special Electro Spindle, which can reach 12000rpm, it is a special machine can do a first mill and end mill in the same machine. The Y-axis design is a perpendicular type, and match with our moving column machine structure, the Y-axis have complete movement. It will not have dead space for the travel. (Y-axis travel /-130mm).

Max. swing: 750 mm

Max. turning diameter: 670 mm

Max. turning length: 1700 mm

Bar capacity: 78 mm

X-axis travel: 600+50 mm

Y-axis travel: ±130 mm

Z1-axis travel: 1750 mm

Z2-axis travel: 1725 mm

B-axis angular stroke: 240°(-30°~+210°) mm

Spindle speed(chuck): 3500 rpm

Spindle nose(chuck): A2-8/10"

Spindle speed(electro): 12000 rpm

X/Y/Z1/Z2-axis rapid traverse: 30/24/30/30 m/min

Tool storage capacity: 40 T

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The Main characteristics of Turn-Mill machine MT-540 are the orthogonal structure and rotating mill head, offering C, Y and B turn-mill capacity.

The orthogonal structure design provides wide range of travel and high dynamic rigidity. Turning combined with mill head can cut simultaneously from different direction, reduce cycle time and improve parts accuracy.

Compact and flexible machine, the MT-540 comes with maximum bar feeding diameter of 65mm. The workpiece with maximum turning diameter of 350

mm and 700 mm length can be machined.

Multi-purposed rotating components offer versatile functionality, like tailstock, loading, milling and drilling, helping the operator in practical using and long

periods of unmanned running.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.