Theme

Digital Transformation

Green Transformation

ADLEE POWERTRONIC CO., LTD.

Product Description :

Product applications:

Surface grinding machine、Internal & External grinder、CNC lathe machine、CNC milling machine, etc.

Adlee manufactures V3 class of AC spindle motor. The motion of AC induction motor makes great performance and this special design for milling machine spindle.

1. V3 class spindle motor.

2. 3 phase AC induction motor has extra low vibration performance.

3. Efficiency conforms to IEC 60034-30 IE3 standards IEC motor.

4. IEC motor specifically designs for grinding machine and low vibration applications.

5. Power range is from 1HP to 20HP.

PRAISE PRECISION IND. CO., LTD.

Product Description :

Products name: Rotary Broaching Tools

Model Number: BCM22-ST16

Features:The ADONAI broaching tools is simple, easy to operate attachment, which produces regular or irregular polygons in blind or through holes having sharp or chamfered edges. The attachment operates with a hunting rotary motion which, in addition to the standard hexagonal and square holes, can also produce grooves, Torxs and other special profiles.

The ADONAI broaching tools can also be used on lathes, CNC automatic lathes, machining centers, drilling machines and special purpose machines for wide variety of standard or special internal and external forms.

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

1.Push type collect chuck fixtures can perform high accuracy of axial position locating by the components and mechanical structure design.

2.The collect chuck could be installed onto the lathe machines rapidly and easily without changing the pulling-pipe when it is switched with the exist chuck.

3.Quick-dismantling design: The front cover can be quickly removed

Simply replace the elastic clip can be replaced to immediately turn different sizes or shapes (round, square, hexagonal...) for increased efficiency and versatility.

4.The components through special technology of hardening treatment to archive high intensity,high rigidity and well durability.

5.Professional precision grinding makes it high-precision, precision repeat clamping accuracy.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

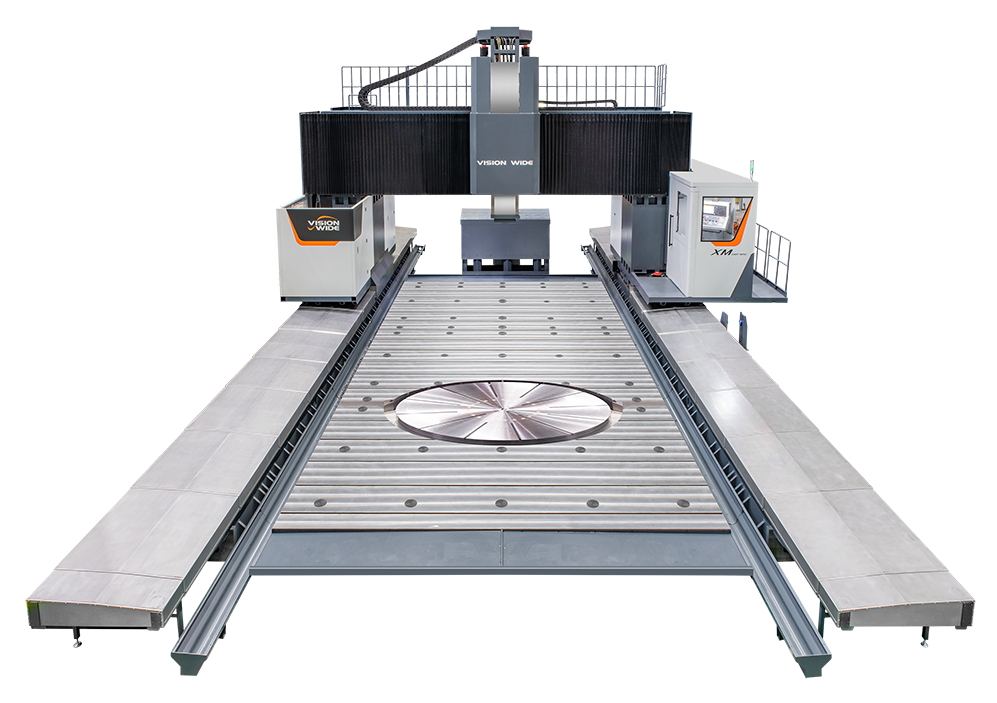

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.