Theme

Digital Transformation

Green Transformation

JAINNHER MACHINE CO., LTD.

Product Description :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

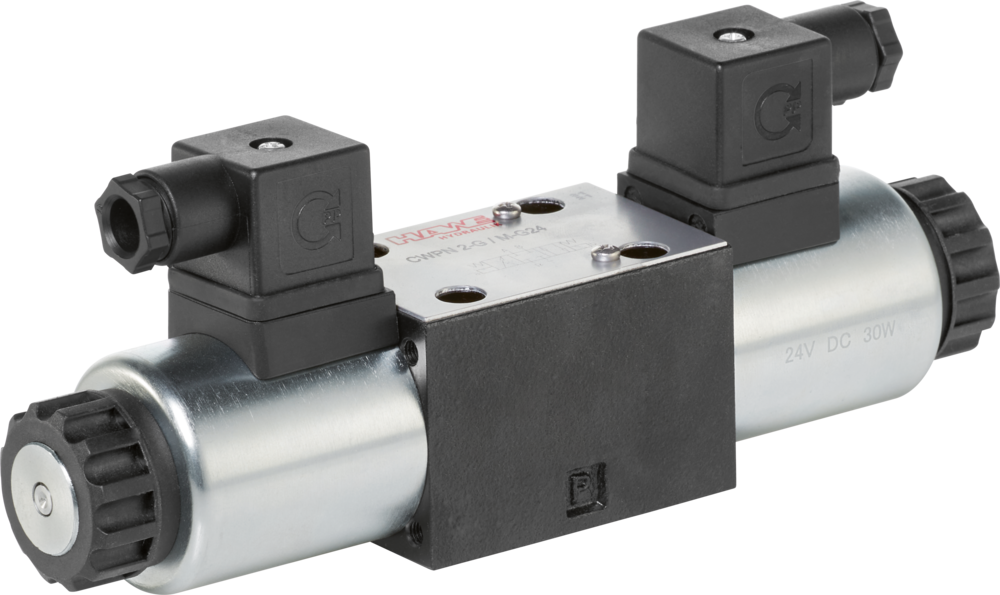

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

GP MACHINERY CO., LTD.

Product Description :

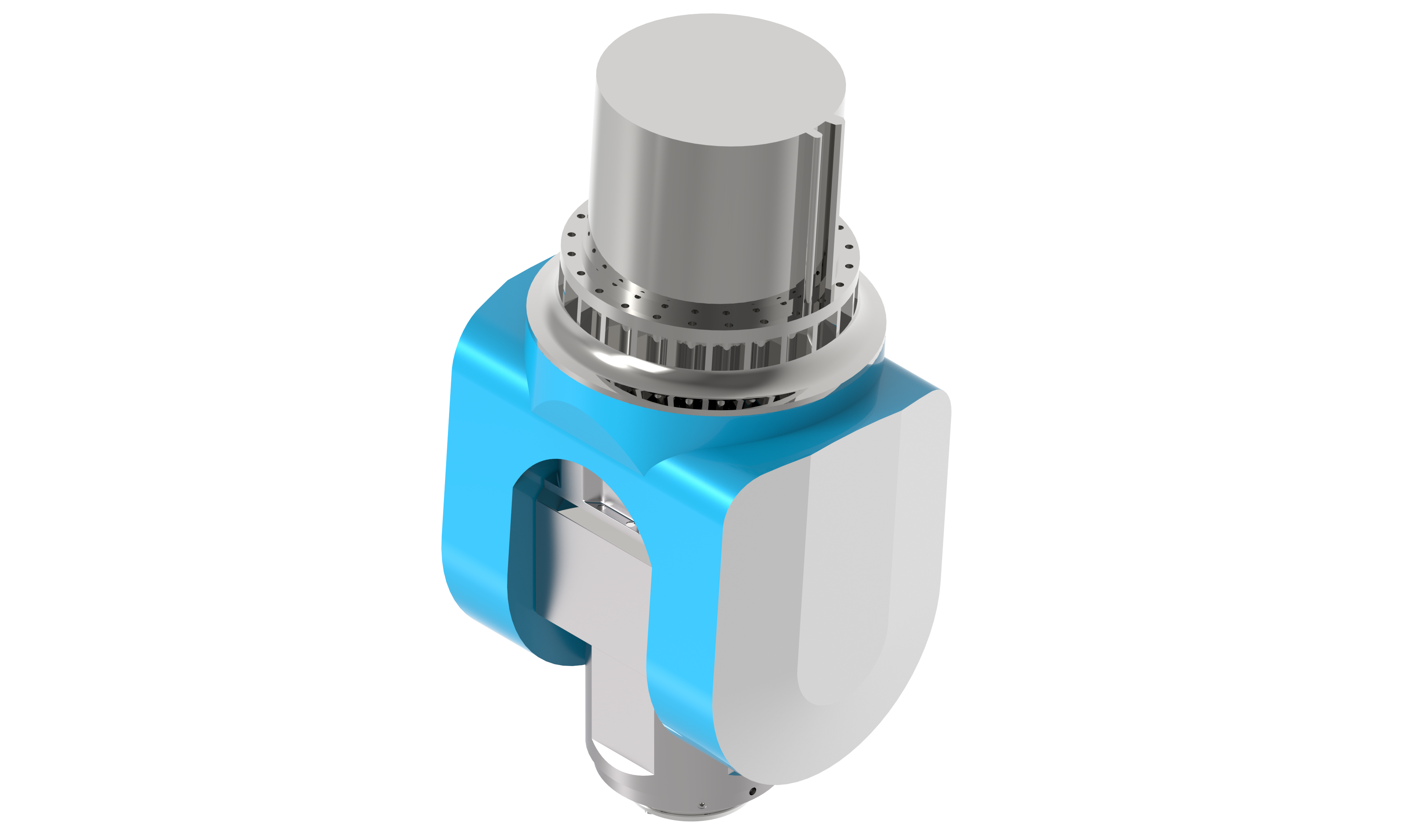

AREA OF USE:

Processing structural components for trains and the air and space travel industries

Construction of models and prototypes

Design

RAW MATERIALS AND PROCESSING:

Finishing steel and cast iron

Roughing aluminium, Zamac, CFRP/GFRP

Artificial materials, wood and ureol

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

TNC7

Innovative | Sustainable | Reliable

Continuously developed, the new software version 18 of the TNC7 fulfills many requests from users and machine manufacturers about ease of operation, reliable processes and enhanced functions.

Discover intelligent functions with which the TNC7 can assist you in your future tasks!

ADLEE POWERTRONIC CO., LTD.

Product Description :

●Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

●AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

KING NICE TECH.CO., LTD.

Product Description :

It can effectively separate the slide oil,foreign matter oil,etc.on the surface of the water tank.Reduce the foul smell produced by the fusion of cutting fluid.

Reduce oil mist and liquid fly rafts causing grease on machinery and workpieces.Free from skin irritation and allergies.

No need to discharge,can reduce the amount of waste oil and wastewater treatment.

Reduce workpiece corrosion,rust,improve machining accuracy and extend tool life.

Purify cutting fluid to stabilize its quality,extend life and improve processing efficiency.

Filter impurities such as suspended solids to prevent backlash form affecting the surface of the motor and theworkpiece.

Stop theproduction of anaerobice bacteria and reduce the frequency of changing cutting fluid.

Reduce the failure rate of pipe and motor blockage.

Reduce labor costs and cleaning time for cutting fluids .Save processing costs for waste oil recovery.