Theme

Digital Transformation

Green Transformation

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

SY2-42 Swiss-type CNC Lathe

■ SY2-42E has Ø42mm maximum bar feeding dia. and provide the option to go with or without a guide bush to achieve optimum machining condition.

■ Main spindle tool system can install 6 radial live tools, 3 axial live tools, 6 O.D. tools, 5 I.D. tools.

■ Sub Spindle tool system can install 8 ER-20 live tools, combines with the Y2 linear axis and C2 rotating axis to perform the more complex turning and milling process.

QUASER MACHINE TOOLS, INC.

Product Description :

This single unit machine features high rigidity, accuracy, and efficiency and offers a high ease of operation with a relatively compact footprint.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The modular design allows for expandable multi-pallet configurations.

MATRIX PRECISION CO., LTD.

Product Description :

Matrix (Formed as Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (Formed as Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (Formed as Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

ZHAO YI HSIN INDUSTRIAL CO., LTD.

Product Description :

Providing clean compressed air without energy consumption

No power required

Applying characteristics of compressed air, hydromechanics and physical principles to design internal structure.

Consumable-free, maintenance-free

Exclusive patented structural design can separate moisture from compressed air without consumables.

Efficiency of air drying and moisture filtration: 99%

Patented high efficiency water-cooled heat exchanger and special air-water separation structure.

High quality, durable, and longevity up to 10 years

No compromise on quality, the product is made in Taiwan.

No electronic and other energy-driven device

Suitable for those who have special needs for compressed air.

7-LEADERS CORP.

Product Description :

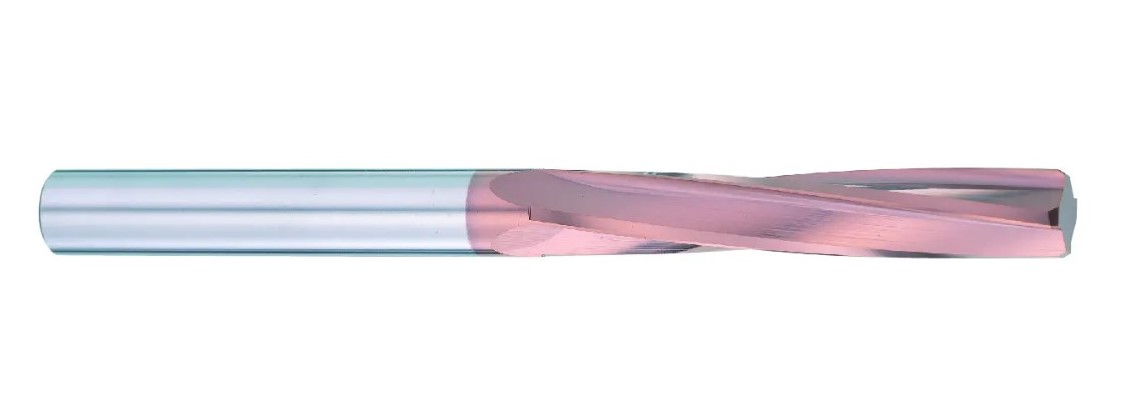

Designed with left helix and right cutting flutes with unequal flute design.

Downward chip evacuation.

Application for reaming different steels below 62HRC, stainless steel, High temp alloys, cast iron, copper…and etc.

Extremely high reaming life with coolant holes for blade cooling.

Nano multilayer coating AlTiSiN with superior wear resistance is suitable for high hardness materials reaming.

Accuracy tolerance: H7 (m5)

0/+0.004mm

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

YG started manufacturing mechanical type hobbing machines since 1963. "Hobbing is our everything" is the slogan in YG. From it, we can say that YG has very good experience in hobbing machines design, and manufacturing.

YG uses HERA as a name for their CNC hobbing machines series. They have wide network in Europe, America and Asia with experienced and professional companies sell HERA there. The HERA series hobbing machines are all full CNC control. They have strong and rigid machine frams. YG uses world class one transmission elements with Fanuc and Siemens full package controller and servo units on their HERA series . It makes HERA has good start point and it really does.

In Taiwan, ATMAX is the agent of YG. ATAMX helps YG sell the HERA series. It is successful already that there severl users are using HERA manufacturing their high precision gear parts.

We always welcome new friend joint us.

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

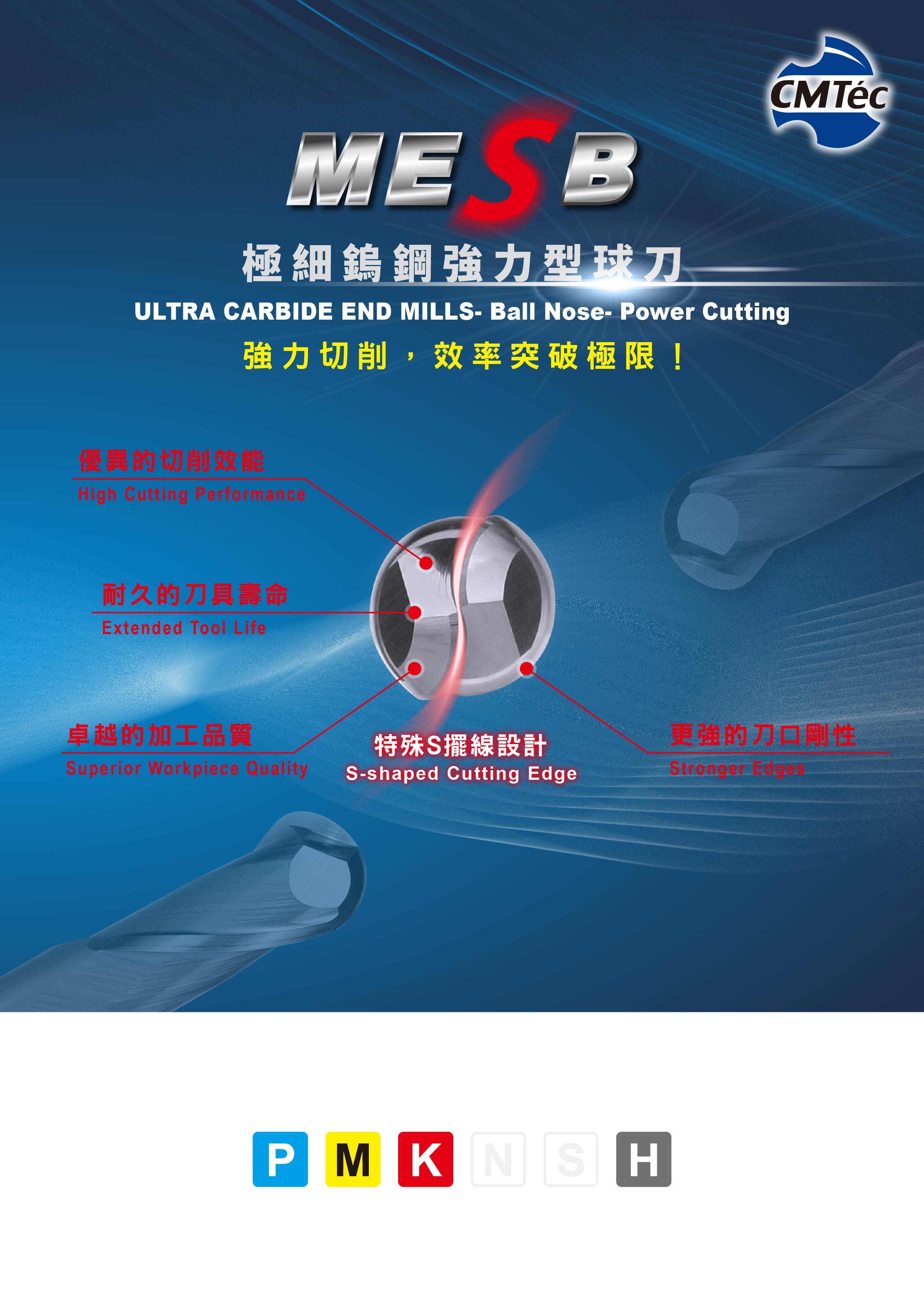

★ Cutting edges and workpiece reduce contact area, lower cutting resistance and boost efficiency.

★ Cutting edges distribute cutting forces evenly, reducing wear and extending tool life.

★ Minimizes vibration during machining, improving surface finish and precision.

★ For copy milling alloy steel, hardened steel (≦60°HRC), stainless steel and cast iron.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1. Stable construction, strong rigidity, low vibration and high cutting

accuracy.

2. Floating feeding method makes aluminum extrusion or material with a

little curve feed easily.

3. Extraordinary horsepower design. Horsepower can be adjusted

according to the demand of saw blades. It cuts fast and has great

productivity.

4. Two saw blade lubricating devices for powerful spray cooling and auto

cooling via cooling liquid.

5. Electronic saw blade protection device and automatic saw blade

stopping device ensure operational safety and the smoothness of the

sawed faces.

6. Patent, After cutting, separating work piece before cutting tool moves

backward, machined surface will be shiny without tooling trace, the life

of saw blade is long.

7.Digit display allows for easy, accurate and fast length adjustment.

8. Applicable for sawing and cutting aluminum, aluminum alloy, brass

alloy, brass and plastic.

9. Control knob provides easy central control and operation.

10. Automatic material-absence sensing and stopping device.

11. Can be equipped with a sawdust collector for clean and convenient

sawdust collection.

12. Action as below:

Put into the material, automatic feeding, automatic positioning,

automatic cutting, can be cutting round, square shaped, head material

and tail material are automatically separated.

GSTC TECHNOLOGY CO., LTD.

Product Description :

APPLITEC is a Swiss company founded in 1987, specializing in the production of precision cutting tools, with a focus on providing high-performance solutions for small parts machining. Their tools are primarily used in CNC Swiss-type automatic lathes, specifically designed to meet the precision machining needs of industries such as medical devices, watchmaking, electronics, and aerospace.

APPLITEC’s product range includes turning tools, drills, milling cutters, and special application tools, all known for their high precision and durability. These tools help improve machining efficiency and extend tool life. The company is committed to continuous innovation, offering customized tooling solutions tailored to meet the increasingly complex demands of modern precision manufacturing. APPLITEC’s products are highly regarded in the global market, especially in applications where superior precision and reliability are critical.