Theme

Digital Transformation

Green Transformation

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.

Fulson Industrial Co., Ltd

Product Description :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 3mm-20mm End Mill Re-sharpening , Adjustable Angle

Precise Grinding Results , Precision Assurance within 0.02mm

Center Cutting Available

High Accuracy Balance between each flute of the End Mill

Easy to Operate , grinding an End Mill within 1 minute.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14 kgs.

EARTH-CHAIN ENTERPRISE CO., LTD.

Product Description :

1.Suitable for large iron and steel plate lifting and moving.

2.Battery type Permanent magnet electronic control structure design, with Neodymium (NdFeB).

No electric power supply required to keep magnetic chuck ON and provides maximized safety in case of power failure.

3.Low-voltage safety warning system, can detect the lithium battery power through the screen at any time.

4.With explosion proof Lithium battery, the charger can be setting 110V~220V.

EPLM (B) can be used for operating 160 cycles after the battery is fully charged.

EPLM (D) can be used for operating 100 cycles after the battery is fully charged

5.The magnetism is divided into 5 levels, it can be adjusted the best magnetic force level for different workpieces.

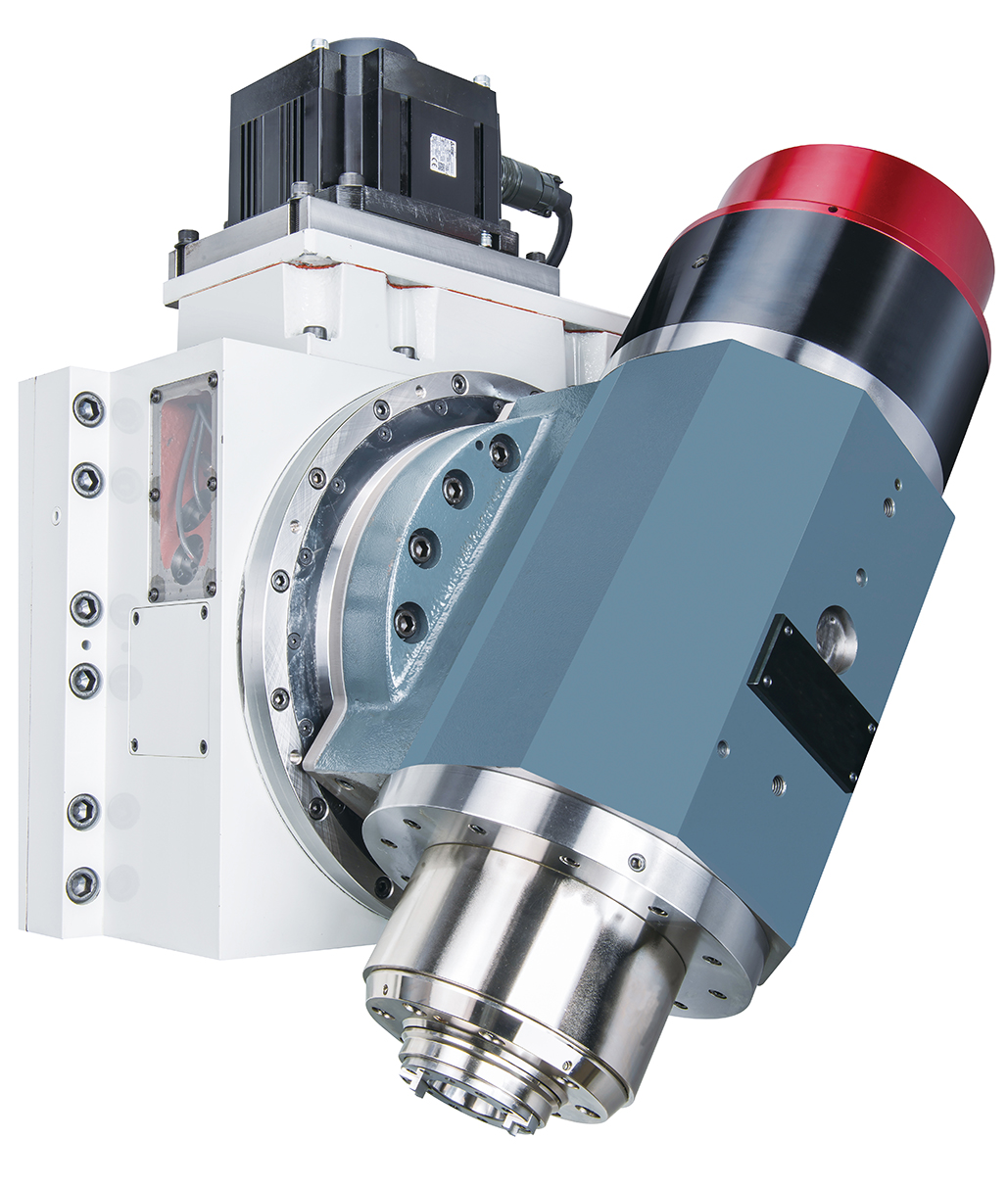

MAINTECH PRECISION CO., LTD.

Product Description :

Axis A-axis

Rotational angle -20°~+110°

Rotational torque 1692 N.m(Continuous)

2412 N.m( S3-60%)

Rotational speed 8.33 rpm

Clamping force 4000 N.m

Positioning accuracy ±8"

Spindle Max. speed 6000 rpm

Spindle Max. torque1000 Nm

Spindle Max. Power30 kW

Coolant through spindle 70 bar (Optional)

Encoder HEIDENGAIN ECA 4000 (Optional)

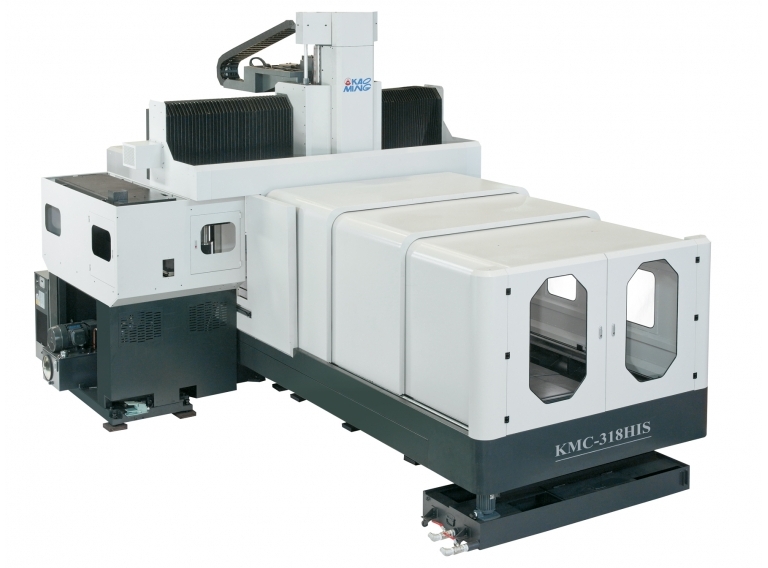

KAO MING MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />

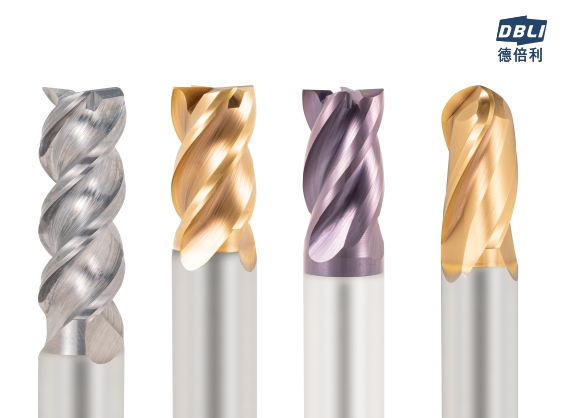

DEEP JET INDUSTRY CO., LTD.

Product Description :

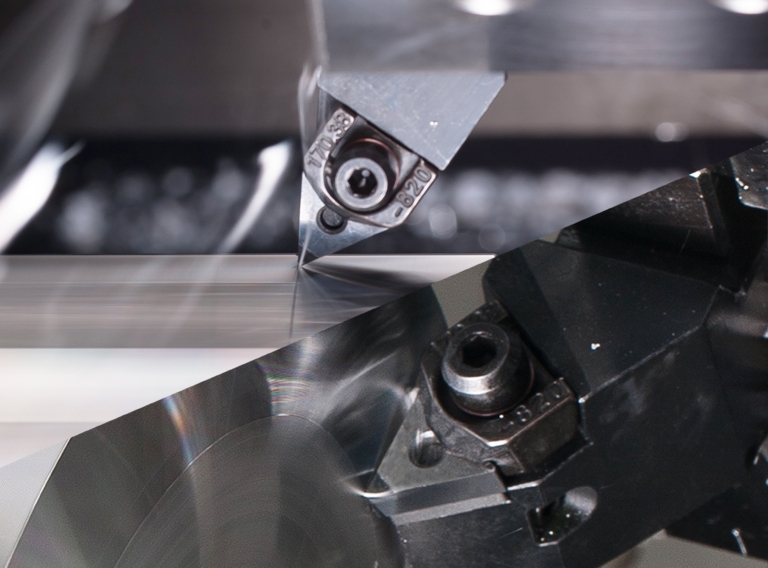

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

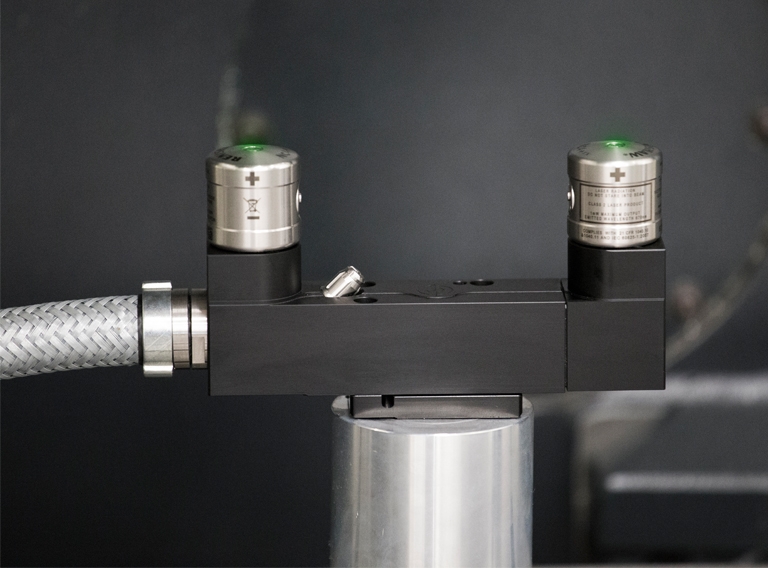

RENISHAW (TAIWAN) INC.

Product Description :

NC4 - 不是只有刀具設定!<br />

<br />

Renishaw 的 NC4 將更快速且更精確的刀具設定優勢附加在製程中且更容易理解。進行加工製程時,尺寸精度取決於變數,包括刀具尺寸偏差、刀具/刀把偏擺與刀具破損。<br />

<br />

Renishaw NC4 非接觸式刀具設定可以:<br />

<br />

• 補償加工製程中出現的誤差<br />

• 自動更新加工機控制器,以補償實際影響,例如刀具磨損<br />

• 於檢測出刀具破損時自動停止製程<br />

• 減少重工、製程妥協及廢品