Theme

Digital Transformation

Green Transformation

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

R PLUS TECHNOLOGY CO., LTD

Product Description :

High performance: design life of more than 50 million times, super high stability

Low power consumption: 0.8/0.3W energy saving design , can be directly driven by PLC

Environmental : the novel inner row structure design

Easy to operate: convenient mode , eliminating the connection time

Provincial space: large flow design and compact

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

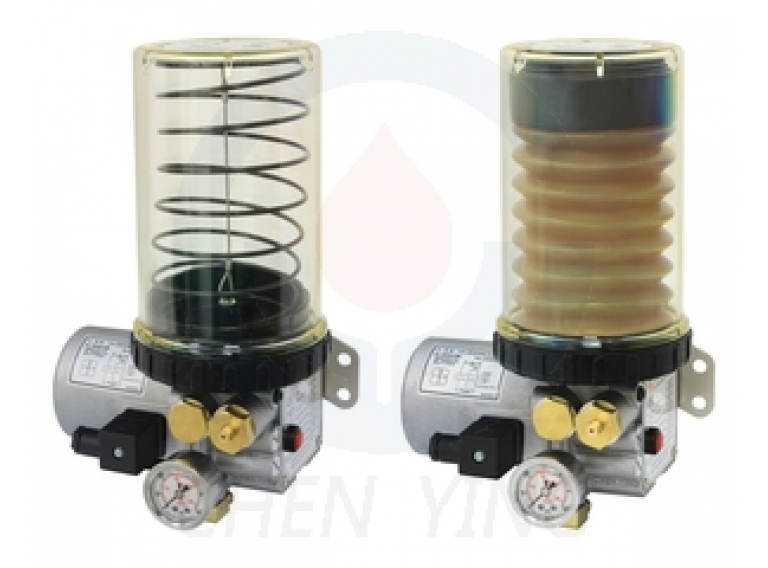

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

Product Description :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.

HABOR PRECISION INC.

Product Description :

> Applications

Spindle, Linear Motor, Ball Screw, Grinding Liquid, CNC Cutting System, CNC Lathe, Other Machining Center

> Feature

Prevent deterioration of liquid.

Open coil type heat exchanger can prevent the obstruction problem of liquid circulating system.

Advance the speed of process.

Maintain the stability of dielectric fluid, advance the process quality.

Avoid fire risk cause by temperature rise and accumulating of dielectric fluid, advance the working safety.

Reduce the wastage of electrode.

Prevent the spreading of foul odor air, reduce the air pollution.

Easy operation and low noise.

Made of anticorrosive material.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

LEEKA INDUSTRIAL CO., LTD.

Product Description :

LEEKA manufactures all kinds of leveling feet and heavy duty wheels. Our product category included leveling legs, adjustable leveling feet, industrial caster wheels and leveling casters.

Commonly used in industrial cabinets, transportation, compressors, generators, food industry equipment and so on. All products can be customized according to customer demand for different sizes, specifications and materials.