Theme

Digital Transformation

Green Transformation

DAH LIH MACHINERY INDUSTRY CO., LTD.

Product Description :

龍門型結構,高速加工極穩定。<br />

12,000 / 15,000 rpm高速直結式主軸。<br />

X, Y, Z軸全配置滾柱型線軌。<br />

X, Y, Z軸快速進給率30米/分。<br />

獨創主軸熱補償功能。<br />

立柱結構左右對稱,為最佳熱平衡設計。<br />

X軸獨立於床台上,Y軸獨立於立柱上,無重疊之負荷。<br />

工作台全行程支撐無懸垂,偏移問題,確保最佳加工精度。<br />

三軸滑軌配置線性滑軌,形成穩定順暢,並兼顧高速加工之需求。<br />

衝錘式主軸頭、開頂式護罩。<br />

滾珠螺桿中空冷卻。

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

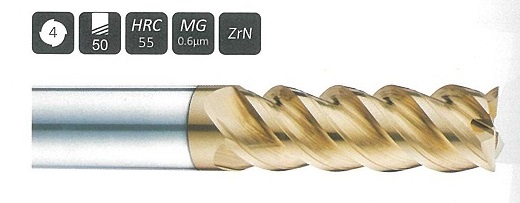

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

QUASER MACHINE TOOLS, INC.

Product Description :

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

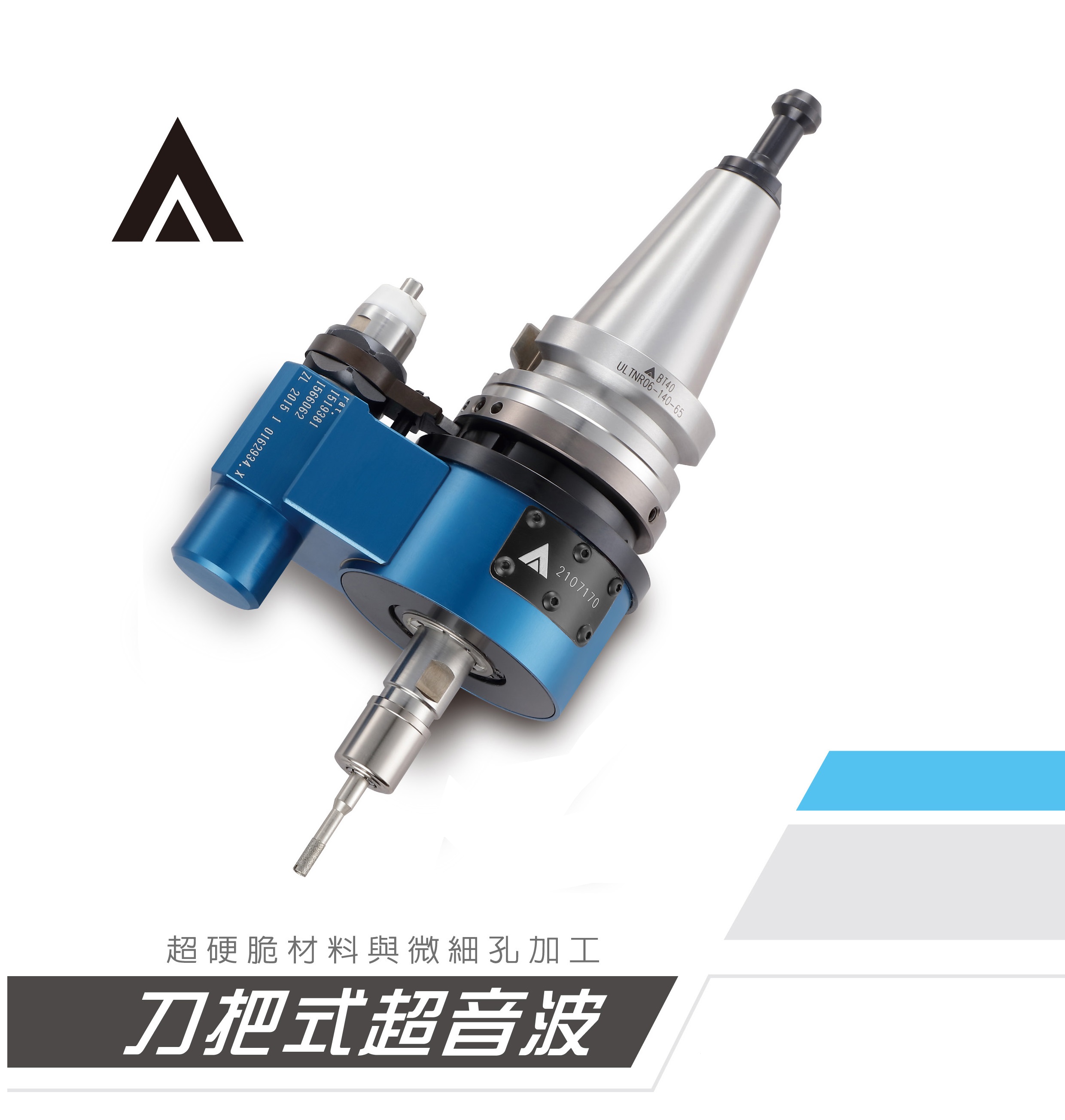

ACROW MACHINERY MFG. CO., LTD.

Product Description :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

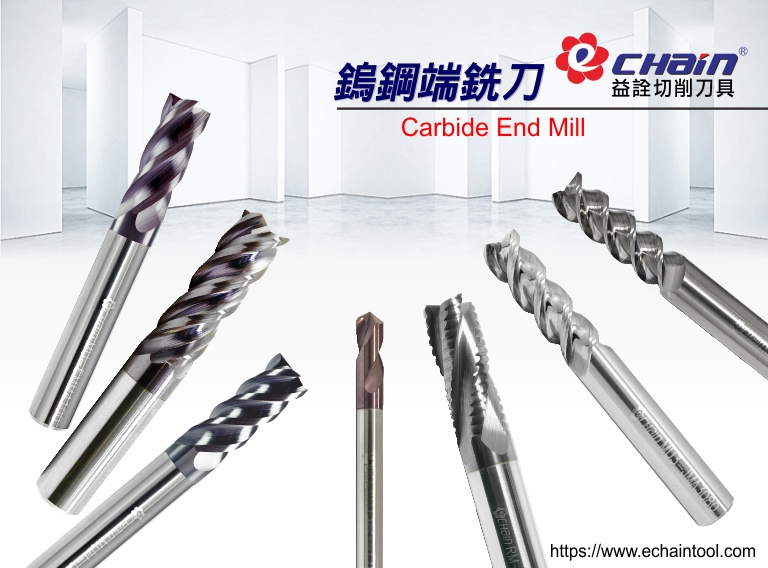

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"