Theme

Digital Transformation

Green Transformation

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve the

efficiency of operators.

OWNNER INDUSTRIAL CO., LTD.

Product Description :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.

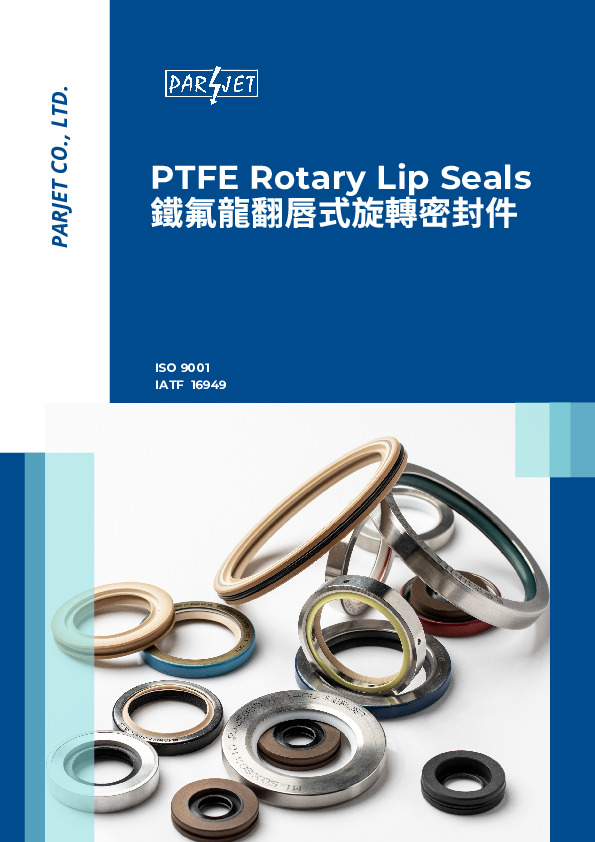

Parjet Co.,Ltd.

Product Description :

HiPerLip®, also known as PTFE Shaft Seal, is a rotary shaft seal with a PTFE sealing lip and metal casing. The rotary seal is ideal for sealing high-speed rotary applications with very low friction and minimal power draw to achieve better performance, higher response, and precision. Thanks to excellent PTFE compounds and the unique sealing lip construction, the PTFE rotary lip seal with metal case provides superior performance over conventional rotary oil seals, especially in high rotary, poorly lubricated, highly corrosive, high temperatures, and other extreme working environments. Typical temperatures range from -60°C to 200°C (-76°F to 390°F), and shaft speeds up to 30 m/s (5,905 fpm) for low pressure applications.

DEEP JET INDUSTRY CO., LTD.

Product Description :

1.Special cutting-edge design with low resistance to reach better chip-off from the groove. This shows the tool's stability in high speed machining.

2.The special coating enhances the anti-oxidation and wear resistance to increase high speed performance.

◆Carbide Drills With Internal Coolant Holes:

Internal coolant holes can highly increase the performance of cooling and chip removal rate.

◆Carbide Flat Drills:

Good for curve and inclined surface machinning.

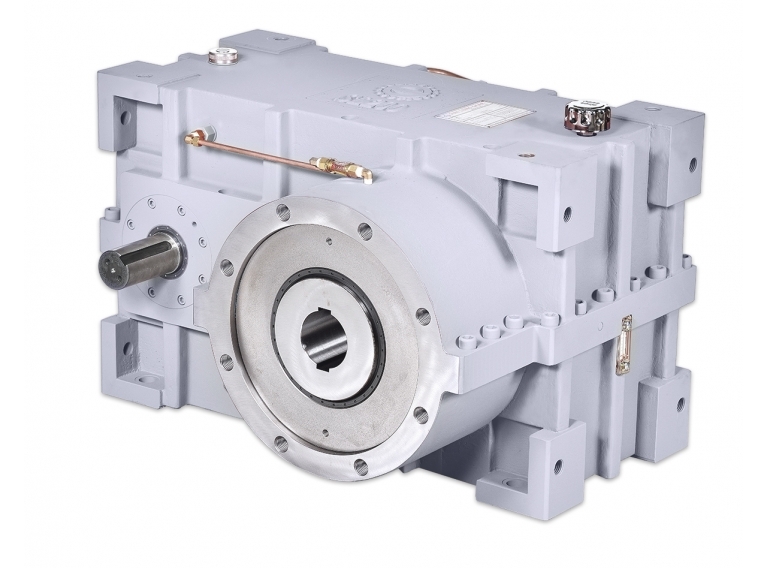

SUN LUNG GEAR WORKS CO., LTD.

Product Description :

【SL5 ~ SL250系列】 三隆研發團隊依AGMA (美國齒輪製造協會) 標準規範設計,經電腦模擬運算及應力分析安全強度之計算,創造出最佳傳遞效率、低噪音、高扭力之優質齒輪箱組合架構。搭配內部高精度齒輪結構及維修方便性設計出最實用、最美觀之獨特外型。齒輪箱上下左右的出力方向均可依客戶需求,提供最完整的解決方案。內部元件採用最高品質SKF或FAG軸承及最有效的二層防漏油NOK油封裝置與超耐磨鍍硬鉻強化處理,均為最優質確保品質的設計。本公司齒輪箱均經嚴格品管檢驗測試,對於噪音、工作溫度、振動完全符合綠能環保標準。

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The Machine Center for next generation — TLV-850II

Applied field: general hardware processing, mold processing, precision parts

TLV-850II is known for its stability and capability of manufacturing with its high rigidity, which adopts the advantages from TLV-850. Furthermore, it applies the structure which fits the current trend.

-T-slot is used with the common specialization: 18mm

-Z-axis is adopted with the design of high rigidity, a bigger motor, and the strengthened structure so that it leads to perfect swarf performance.

-The tool magazine is well designed to provide the best stability.

-A stronger saddle and an enlarged base frame are also installed to stabilize the performance on cutting.

Skeye Machinery co.,LTD

Product Description :

The appearance and structural dimensions of the YRTS high-speed turntable bearing (referred to as YRTS turntable bearing) series are the same as the YRT series, but the internal structure is different from the YRT series. This determines that the YRTS turntable bearing series has a higher limit speed than the YRT turntable bearing series. The friction torque is lower and more uniform than that of the YRT turntable bearing series. Therefore, this series can be selected for applications that require relatively low friction but relatively high speed, such as bearings used for shafts driven by direct drive motors.

The radial rollers use nylon retainers, so that the YRTS bearing has the characteristics of high limit speed and low and stable friction torque, so this kind of bearing is suitable for engines with torque.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.