Theme

Digital Transformation

Green Transformation

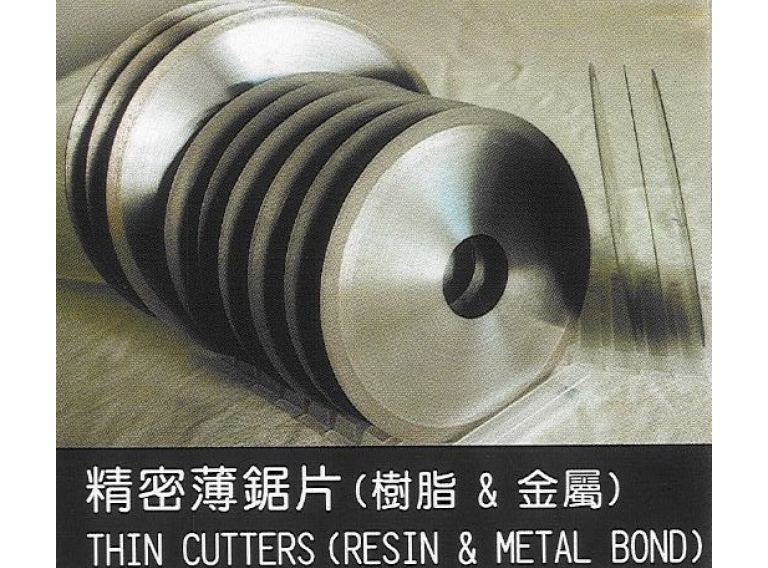

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

KAO FONG MACHINERY CO., LTD.

Product Description :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

HISEN ENTEPRISES CO., LTD.

Product Description :

1. Crystal power supply unit, using high-power SiC MOSFET or IGBT.

2. Rotary Table scanning quenching machine, driven by a servo system with ball screws and linear guides, ensuring stable travel speed. Monitoring of each workpiece's processing data ensures consistent output quality (voltage, current, power, frequency, energy, quenching fluid pressure, flow rate, temperature, water level).

3. Quenching fluid cooling system, with water tank and piping made of 304 stainless steel, capable of monitoring water level, pressure, temperature, and flow rate data.

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

New technology for polygonal milling, one-piece design, optimised machining efficiency!

●Efficient Polygon Milling: Supports multi-surface machining of 2, 4, 6, 8, and more. A single tool can handle multiple requirements, flexibly adapting to various lathe equipment and speeds.

●Integrated Blade Design: The blade and cutter head are welded as one unit, eliminating the tolerance issues common with traditional tools, enhancing installation ease and cutting precision.

●Optimized Production Efficiency: A more efficient cutting process that reduces machining time, lowers costs, and significantly improves production efficiency.

●Precision Machining Solution: Overcomes the precision degradation problems of ordinary milling cutters, providing stable and high-quality machining results.

Choose SONG GIA's Polygon Unit for Sub Spindle to enhance your machining efficiency and achieve the perfect combination of high efficiency and precision!

SONG GIA provides you with diversified CNC drilling/milling whole series options to meet your various processing demands. We also provide customized design and production according to customers’ different requests.

https://www.songgia.com.tw/en/products/live-tools-for-cnc-lathes/polygon-unit-for-sub-spindle-strb412201

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

- “U” shaped base is one-piece fabricated for maximum stability and rigidity.

- X-axis federate is transmitted through a specially designed rotating nut, it prevents the ball-screw runs out during rotating and makes feed motion response faster.

- Coolant inter ball-screws on three-axis prevent ball-screw deformation, it suppresses thermal growth and thermal displacement on the ball-screw while assuring smooth feed motions and high positioning accuracy.