Theme

Digital Transformation

Green Transformation

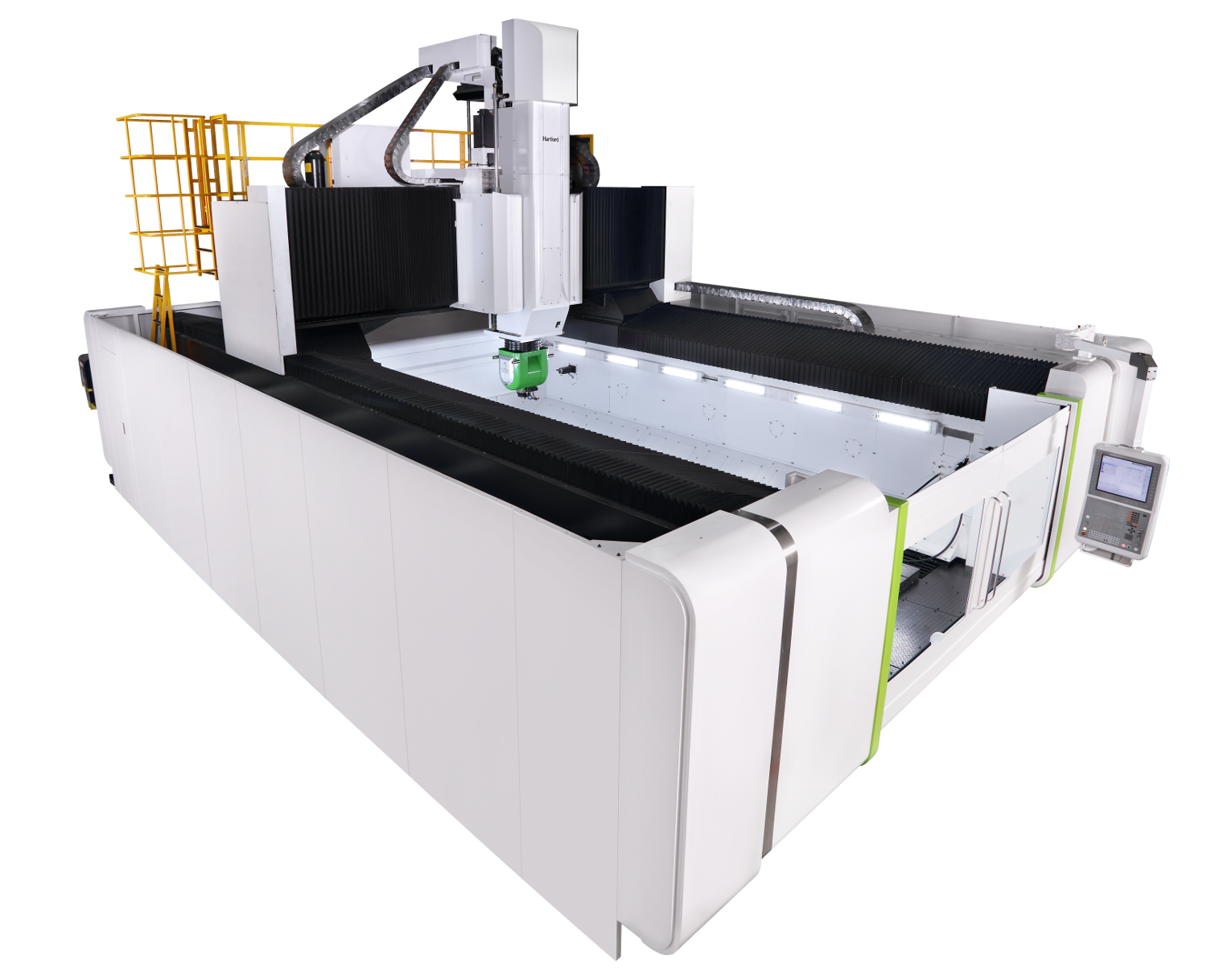

KAO FONG MACHINERY CO., LTD.

Product Description :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

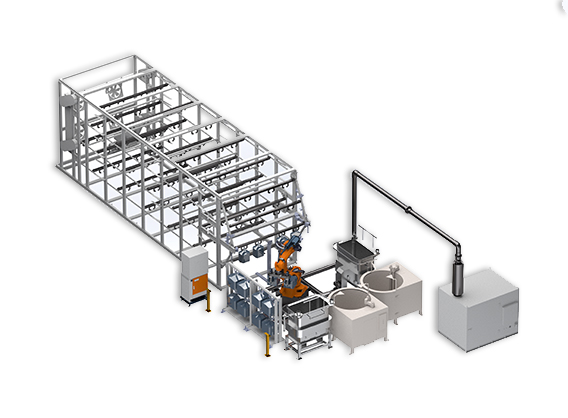

YING HAN TECHNOLOGY CO., LTD.

Product Description :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The CNC Tapping center, designed and manufactured by TMT, is your best choice in drilling and tapping work. The machine series employs a high speed traverse on the three axes to significantly increase drilling and tapping efficiency. The entire machine is ruggedly constructed to assure the highest machining accuracy.

-The casting parts of machine are manufactured from high quality Meehanite cast iron, rib reinforeced and stress released to assure it remains deformation-free year after year.

-Three axes slideways are mounted with precision linear ways. Extra large span between ways. High feed rate and superior stablility.

-Servo motor directly drives ballscrew, featuring high positioning accuracy without backlash problem.

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

MANFORD MACHINERY CO., LTD.

Product Description :

The casting body with high rigid structure and industrial aesthetics adopts angular shape, and the three-color corporate identity of red, black, and white.

The side door is used to observe the workpiece processing and calibrate the workpiece.

The handle of the operation box is conveniently designed for front and rear and 180° rotation.

Table size: 850 x 500 mm

Pallet changing time: 11 ~ 13 sec

Table positioning accuracy: 0.01 mm

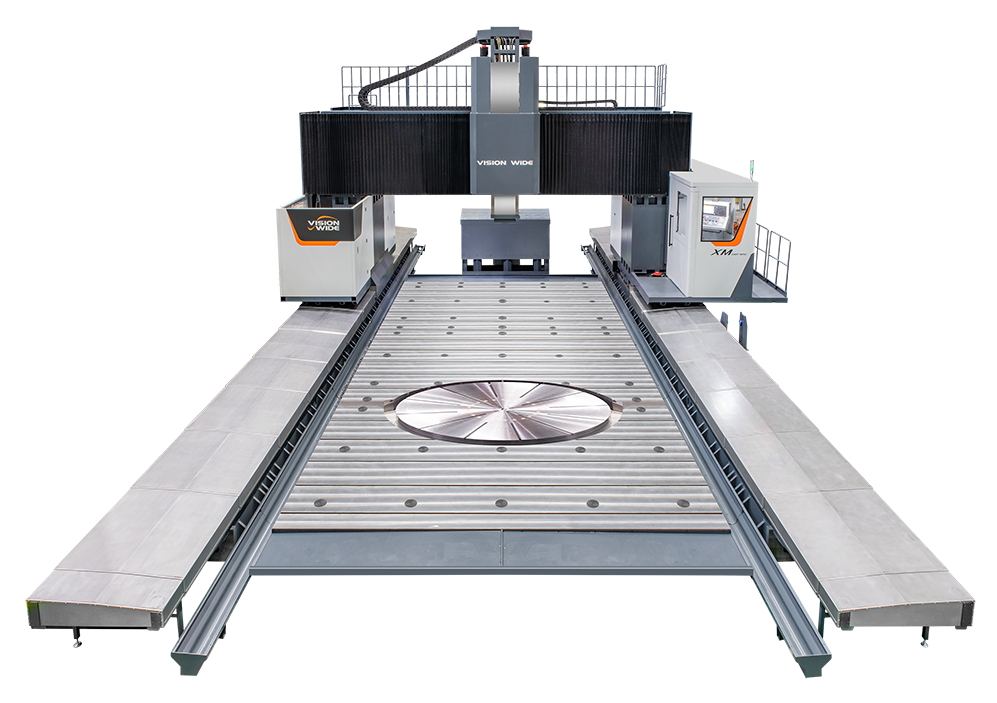

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

- “U” shaped base is one-piece fabricated for maximum stability and rigidity.

- X-axis federate is transmitted through a specially designed rotating nut, it prevents the ball-screw runs out during rotating and makes feed motion response faster.

- Coolant inter ball-screws on three-axis prevent ball-screw deformation, it suppresses thermal growth and thermal displacement on the ball-screw while assuring smooth feed motions and high positioning accuracy.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Optimized structure configuration

- The base and column are structured as one-Piece casting, which eliminates possible tolerance of the jointing interface.

- Box-opstructure casting and optimal span realize exceptional rigidity and stability.

★Overlapped Axes with 2 Rotating Axes

- Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

★3 Axes Motion Area Partitioned Processing Area

- Effective In addition to space chips removal, promoting Antifouling capability, optimal span realize exceptional rigidity and stability.

★Chip removal function

- Forming one large funnel chips off, high performance chip removal

SHE HONG INDUSTRIAL CO., LTD.

Product Description :

+ X & Y axes linear motor dirven

+ Double ballscrew drive design for Z axes

+ Four linear guideways on Z axes

+ Thermal growth control on Z axes

+ Roller type linear guideways on 3 axes

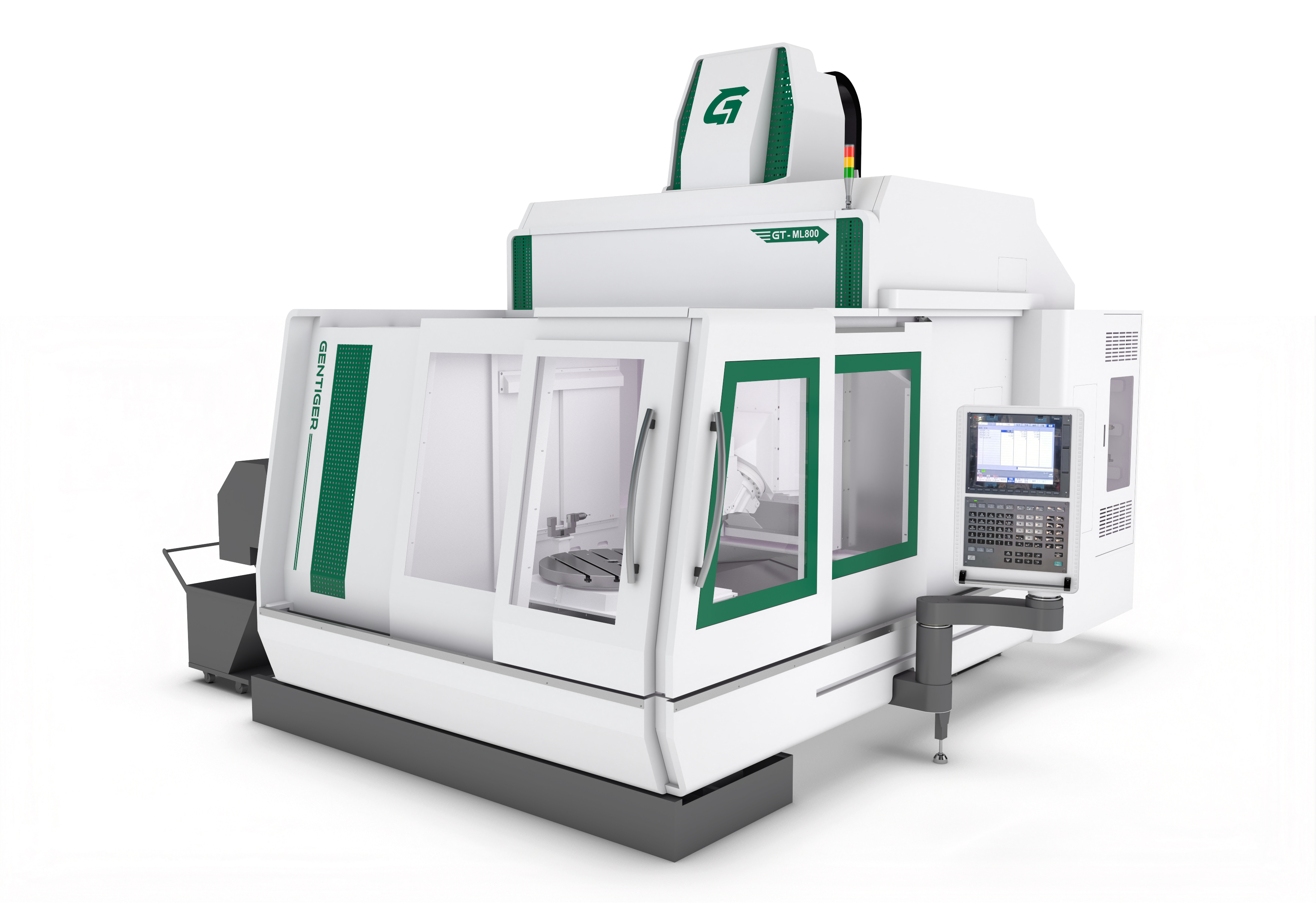

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.