Theme

Digital Transformation

Green Transformation

MANFORD MACHINERY CO., LTD.

Product Description :

The casting body with high rigid structure and industrial aesthetics adopts angular shape, and the three-color corporate identity of red, black, and white.

The side door is used to observe the workpiece processing and calibrate the workpiece.

The handle of the operation box is conveniently designed for front and rear and 180° rotation.

Table size: 850 x 500 mm

Pallet changing time: 11 ~ 13 sec

Table positioning accuracy: 0.01 mm

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧HTT-500, the 5-axis horizontal machining center, is Tongtai's new solution of process integration which will definitely meet the demands on high-mix low-volume manufacturing.

‧Excellent machine rigidity and stability to ensure high accuracy during precision machining.

‧Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

‧Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

‧Equipped with APC (auto pallet changer) system to shorten the machine idle time.

‧Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

- “U” shaped base is one-piece fabricated for maximum stability and rigidity.

- X-axis federate is transmitted through a specially designed rotating nut, it prevents the ball-screw runs out during rotating and makes feed motion response faster.

- Coolant inter ball-screws on three-axis prevent ball-screw deformation, it suppresses thermal growth and thermal displacement on the ball-screw while assuring smooth feed motions and high positioning accuracy.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The Main characteristics of Turn-Mill machine MT-540 are the orthogonal structure and rotating mill head, offering C, Y and B turn-mill capacity.

The orthogonal structure design provides wide range of travel and high dynamic rigidity. Turning combined with mill head can cut simultaneously from different direction, reduce cycle time and improve parts accuracy.

Compact and flexible machine, the MT-540 comes with maximum bar feeding diameter of 65mm. The workpiece with maximum turning diameter of 350

mm and 700 mm length can be machined.

Multi-purposed rotating components offer versatile functionality, like tailstock, loading, milling and drilling, helping the operator in practical using and long

periods of unmanned running.

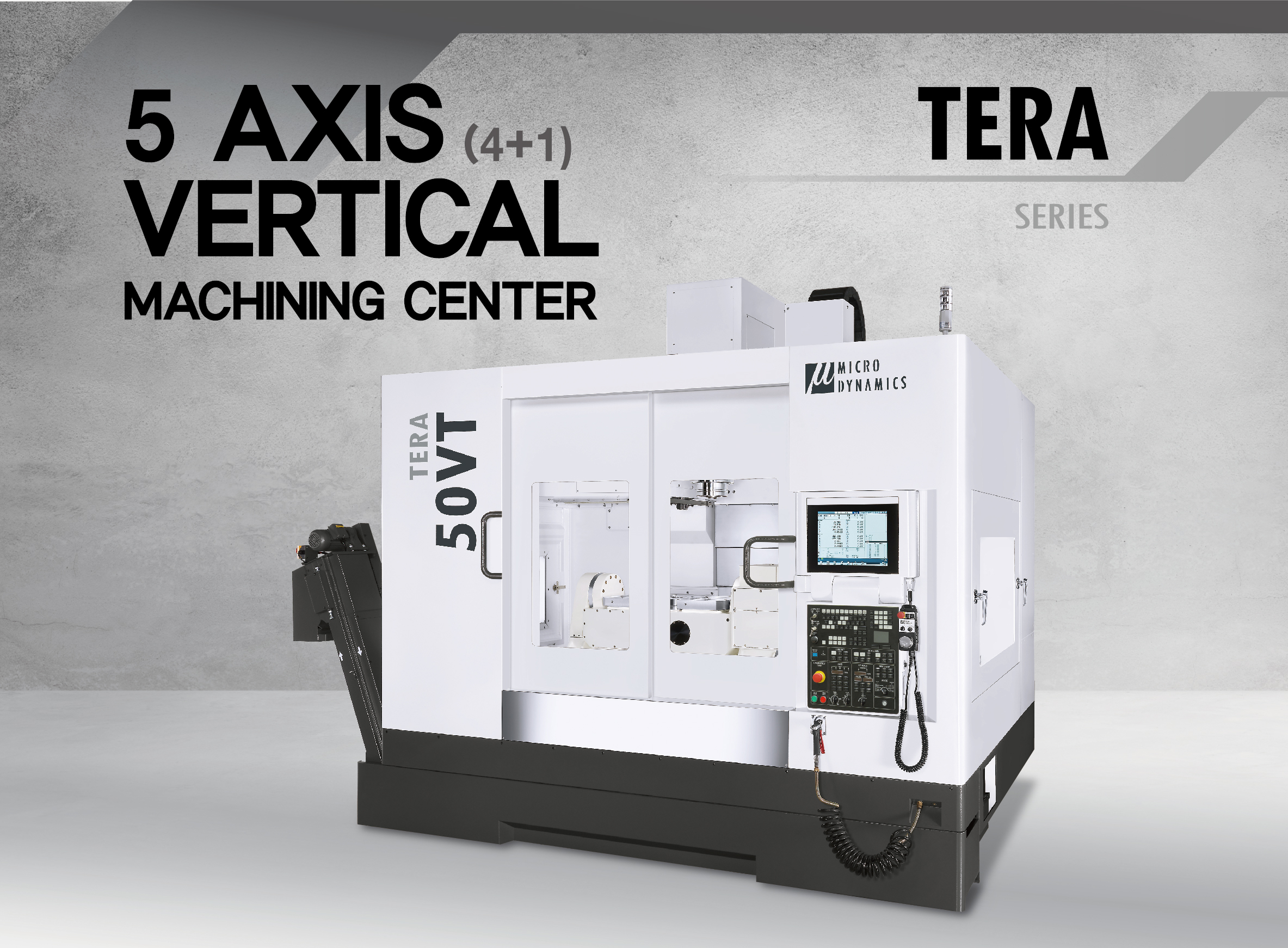

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

1. T structure bed with high-quality cast-iron frame for enhanced rigidity and stability.

2. Extremely rigid mobile column with linear guide ways ensures stability and cutting accuracy while allowing rapid traverse of the X, Y and Z axes.

3. High rigidity roller type linear guideways, rugged massive linear guideways on X, Y and Z axes maintain precision and ensure a rapid traverse rate.

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve the

efficiency of operators.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.