Theme

Digital Transformation

Green Transformation

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

QUASER MACHINE TOOLS, INC.

Product Description :

The MV1 series machines have a legendary history of high quality and proven performance, the New MV184 series has an even greater degree of reliability and performance. The design concepts of the new MV184 series combine advanced technology, performance and value for various machining applications.

Quaser produces this machine layout with the state-of-the-art digital design. Taking into consideration easy repair to reduce downtime. The MV184 series is the choice to increase part production.

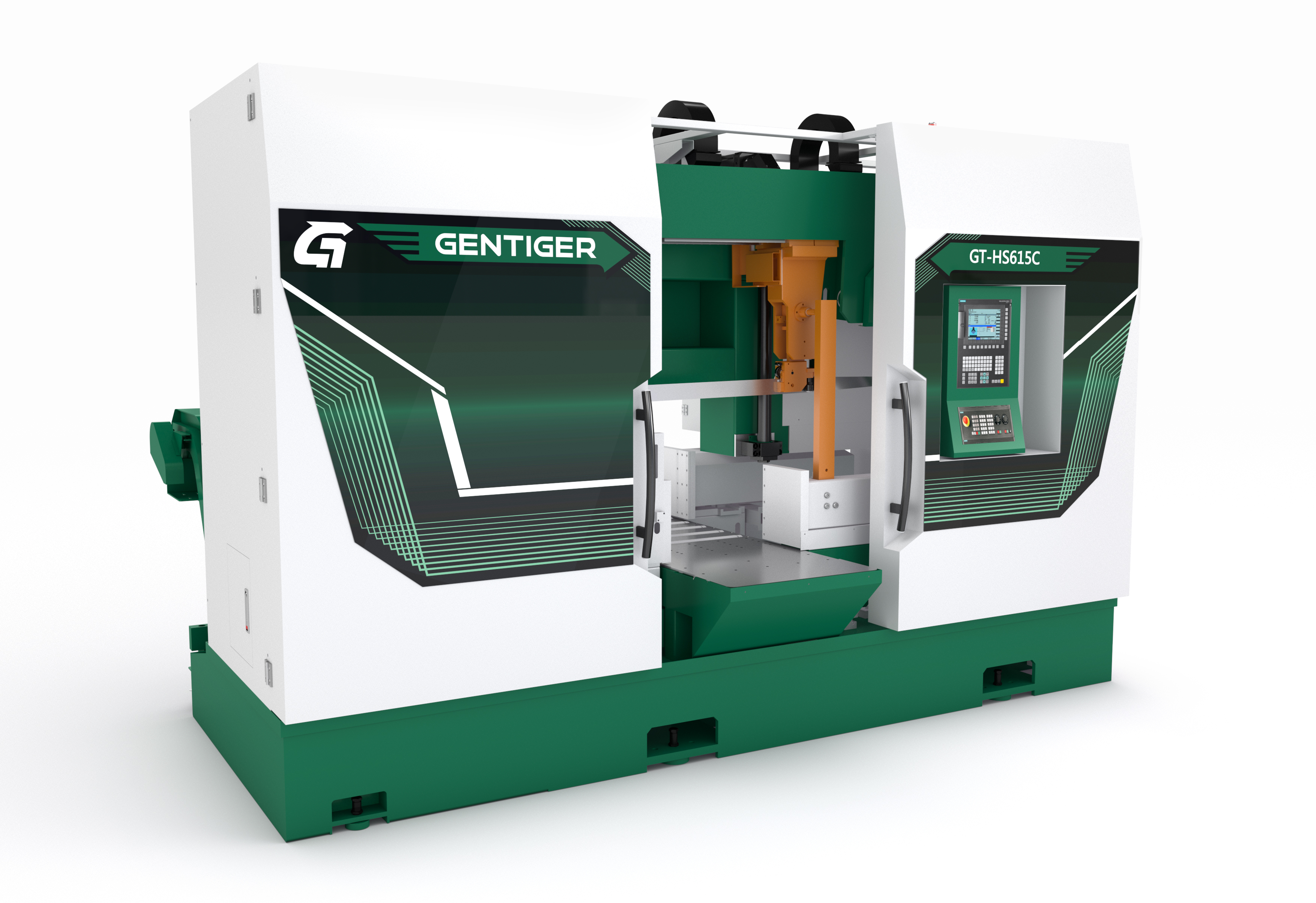

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

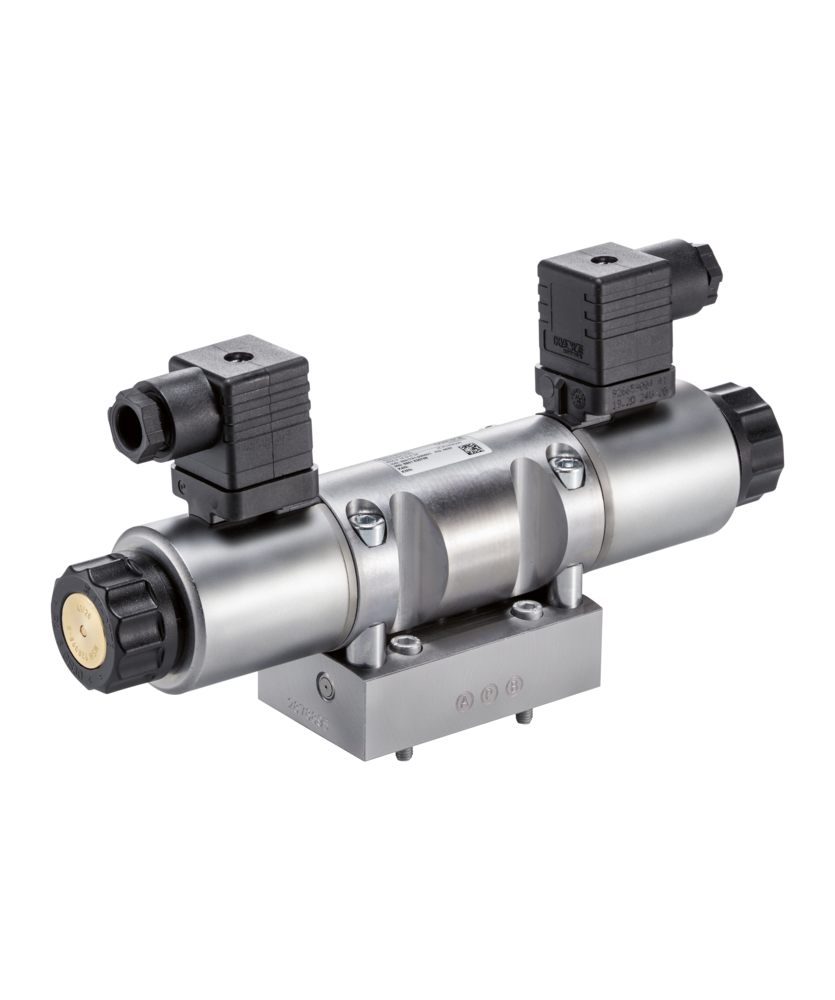

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

KING NICE TECH.CO., LTD.

Product Description :

It can effectively separate the slide oil,foreign matter oil,etc.on the surface of the water tank.Reduce the foul smell produced by the fusion of cutting fluid.

Reduce oil mist and liquid fly rafts causing grease on machinery and workpieces.Free from skin irritation and allergies.

No need to discharge,can reduce the amount of waste oil and wastewater treatment.

Reduce workpiece corrosion,rust,improve machining accuracy and extend tool life.

Purify cutting fluid to stabilize its quality,extend life and improve processing efficiency.

Filter impurities such as suspended solids to prevent backlash form affecting the surface of the motor and theworkpiece.

Stop theproduction of anaerobice bacteria and reduce the frequency of changing cutting fluid.

Reduce the failure rate of pipe and motor blockage.

Reduce labor costs and cleaning time for cutting fluids .Save processing costs for waste oil recovery.