Theme

Digital Transformation

Green Transformation

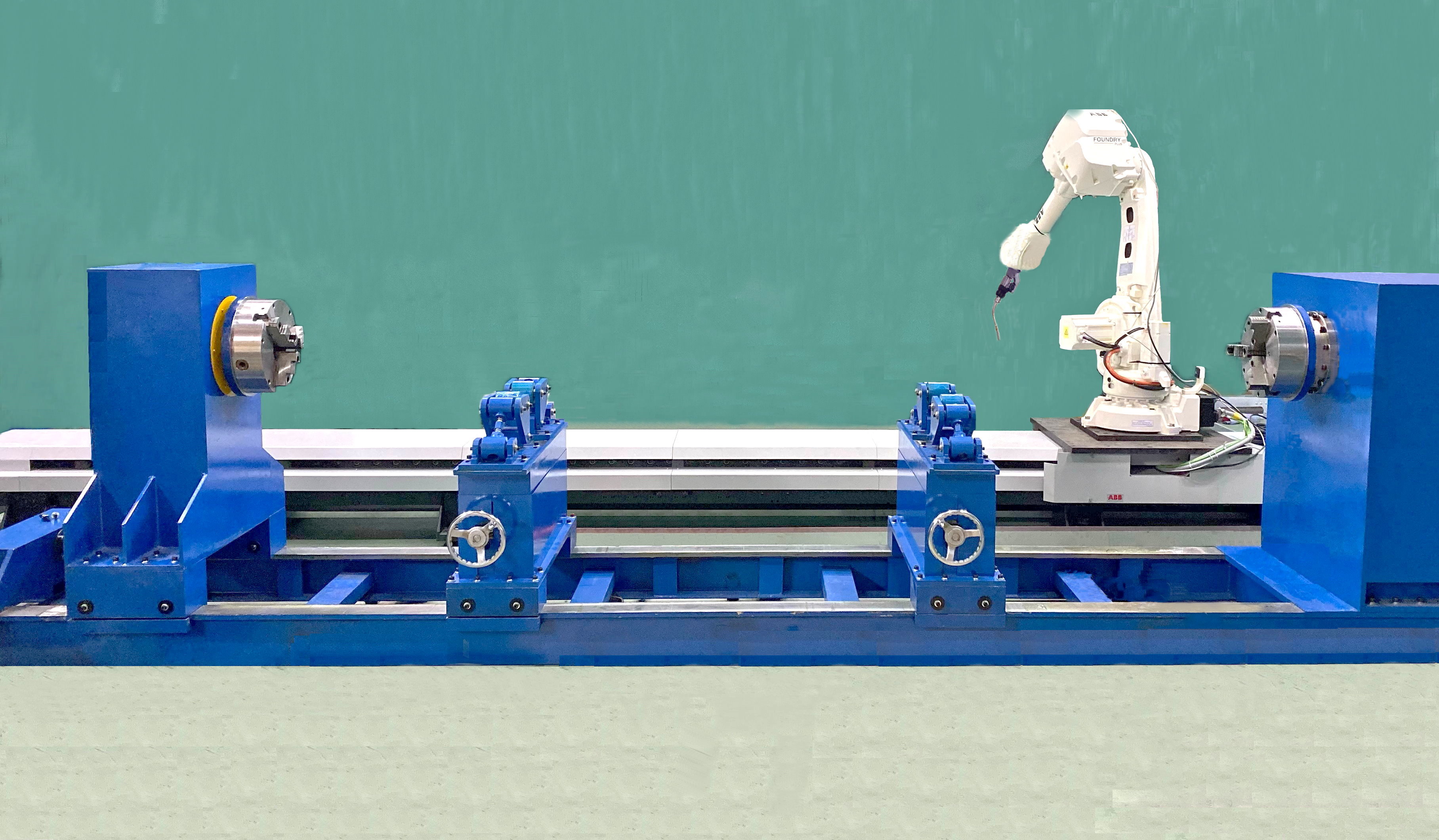

LEPAO ELECTRICITY MACHINERY CO., LTD.

Product Description :

精密定位滑台系統配合銲接機械手臂(Welding Roboter),採多組選擇設定/記憶作全自動銲接加工,

旋轉精準,傳動無間隙,移行定位準確,全自動記憶功能,生產效益

和品質提昇。

移行定位滑台可依客戶工件需求而設計,可適用最大直徑ψ2000mm,最長長度5000mm,適用範圍:精密銲接、運動器材

、航太科技、腳踏車業,汽/機車業..等。

G-TECH INSTRUMENTS INC.

Product Description :

★Multi-Channel Dynamic Measurement: 4-CH simultaneous analog input, compatible to accelerometer, microphone, etc.

★Digital Data Processing: Local real-time computing, data storage, and transmit to data center via ethernet.

★Test & Measurement : Remote Mode--FFT Analyzer;Standalone Mode--Data Recorder & Transmitter.

★Condition Monitoring: Programable multiple I/O interface, connect to controller for intelligent manufacture.

LASER APPLICATION TECHNOLOGY CO., LTD.

Product Description :

◎ To measure 2D, 3D, and 5D point position of robotic arm

◎ To improve mechanical arm's accuracy

◎ To solve arm's drift problem

◎ Easy to install, measure fast and accurately

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

COMETECH TESTING MACHINES CO., LTD.

Product Description :

If you are looking for a low-cost but with great function performance motor driver, then the C2A series will be a great bargain. This series is suitable for motors below 150W, and the small size occupies no space. Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 150W

-Rated Current: 7.5A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485

-Speed Control: Analog input, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Compact size

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

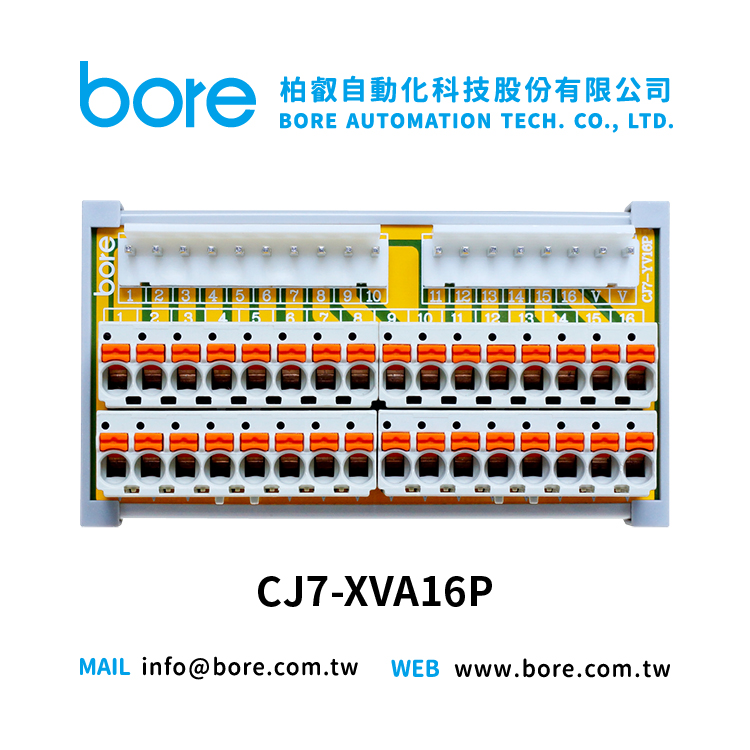

BORE AUTOMATION TECH. CO., LTD.

Product Description :

16 PIN Interface Module with Sensor, equipped with WAGO PUSH-IN Type PCB terminal block, indication LED's for output status , with high quality 3.96 quick connector, fully compatible with variety PLC/CNC controller, Ultra-narrow, space-saving

COMETECH TESTING MACHINES CO., LTD.

Product Description :

RS-485

型號:K0118-000F51A2

通訊速度:9600、19200、38400、115200、921600、1M、2M bps

連接器型式:2P歐式端子

尺寸:38 x 31 x 15 mm

使用環境溫度:0°C~55°C

RS-232

型號:K0118-000F41A2

通訊速度:9600、19200、38400、115200 bps

連接器型式:D-Sub 9P母座

尺寸:33 x 31 x 15mm

使用環境溫度:0°C~55°C

CAN Bus

型號:K0118-000F61A2

通訊速度:1M bps

連接器型式:2P歐式端子

尺寸:38 x 31 x 15 mm

使用環境溫度:0°C~55°C

SHENG FENG TECHNOLOGY CO.,LTD

Product Description :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

BORE AUTOMATION TECH. CO., LTD.

Product Description :

24V DC 16 Channels Relay Module, equipped with high qaulity OMRON G2R-1-E-DC 24V power relay, high quality DECA Double-Deck PCB terminal block, fully compatible with variety PLC / CNC controller, muti-functional protection , optimized installation effort

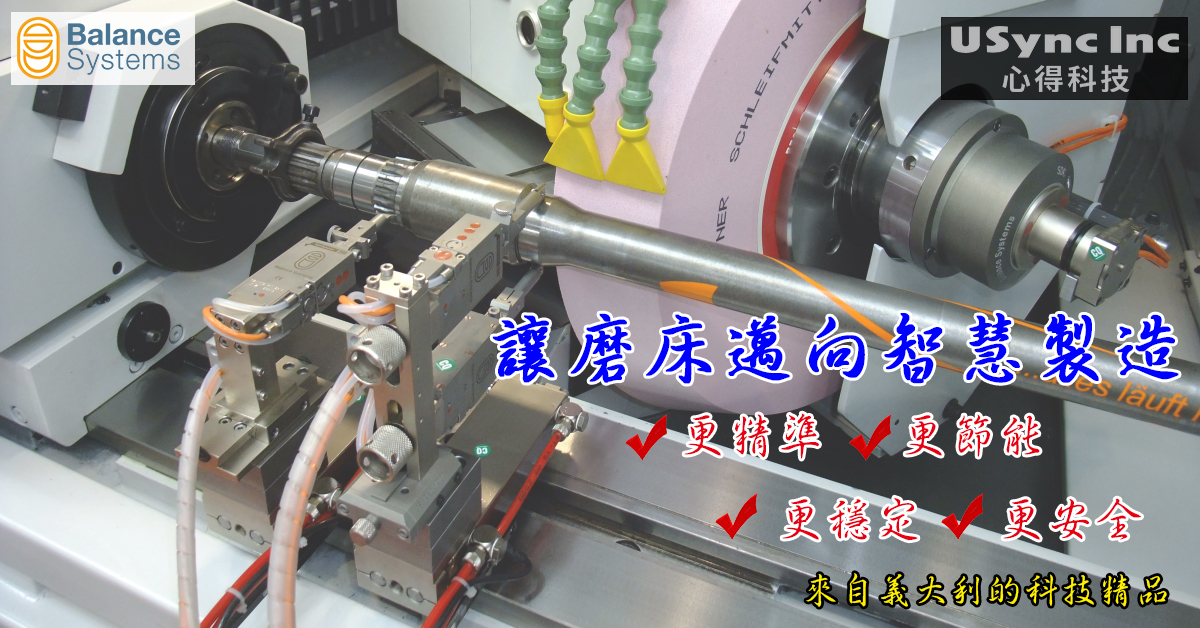

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

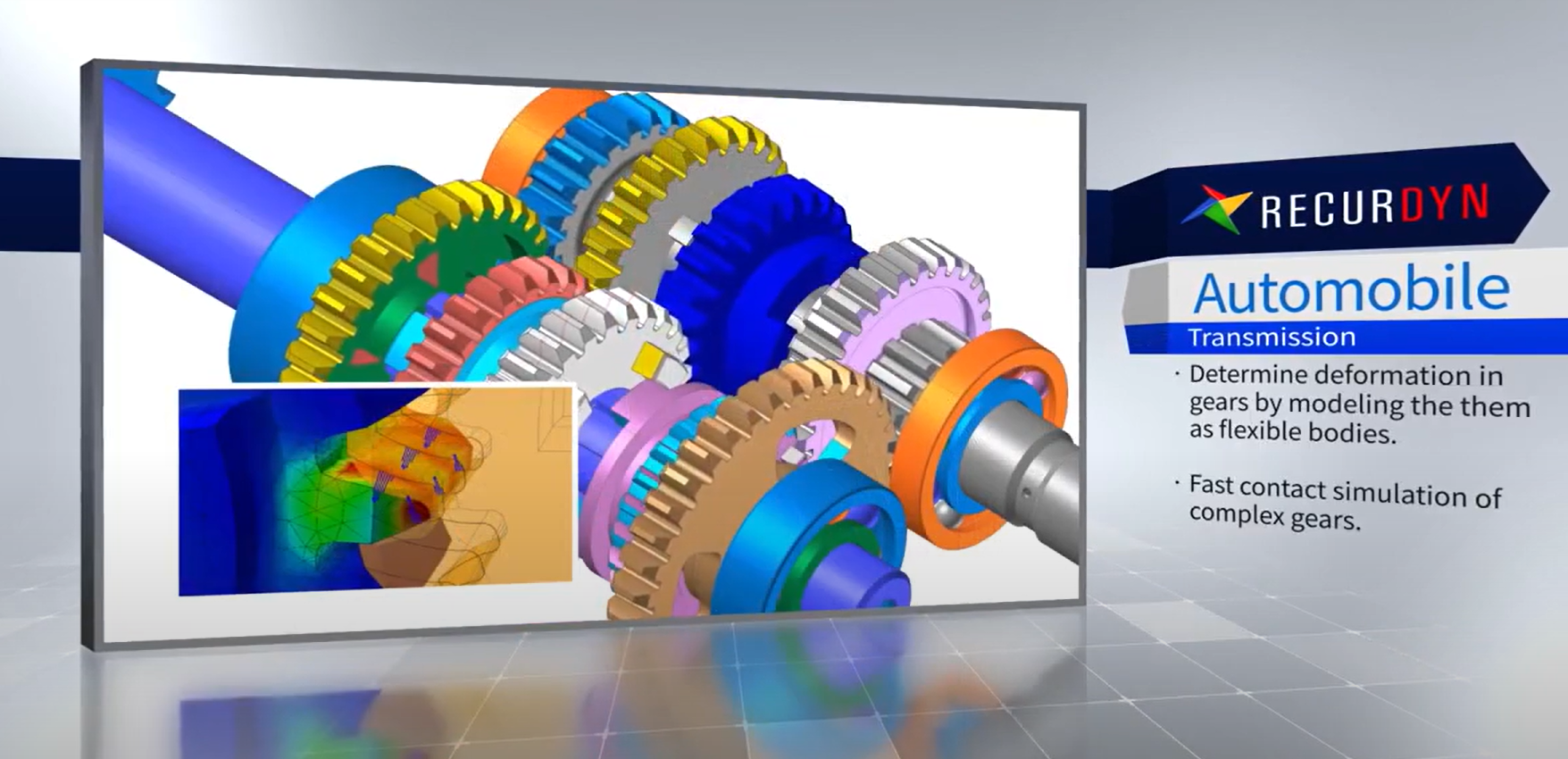

Taiwan Auto-Design Co.

Product Description :

RecurDyn is an interdisciplinary CAE (Computer-Aided Engineering) software based on Multi-Body Dynamics (MBD).

It provides fast and efficient solvers, an intuitive interface, and various libraries.

RecurDyn simulates both rigid and flexible body dynamics by combining traditional rigid MBD with cutting-edge

finite element technology for modeling flexible bodies. In addition to MFBD (Multi Flexible Body Dynamics), RecurDyn

also includes a tightly integrated controller design tool, design optimization, and durability and fatigue analysis.

RecurDyn also supports co-simulation with various other CAE software tools. It enables a seamless co-simulation

environment (Particleworks Interface) for coupled simulations with computational fluid dynamics solver, Particleworks,

allowing for detailed analysis of the interaction of fluids and multi-body systems.