Theme

Digital Transformation

Green Transformation

CIMer Tech co.,Ltd.

Product Description :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.

Administration for Digital Industries, moda

Product Description :

Transforming maintenance history into a digital knowledge base to enhance maintenance efficiency and reduce learning costs.

1.Establishing SOP standard maintenance procedures

2.Uploading text, images, and videos freely

3.Easily accessing through website and app

4.Customizing knowledge base languages based on different countries

5.Calculating average failure rates by region and machine model

6.Maintenance progress scheduling calendar

7.Remote automatic reporting system

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

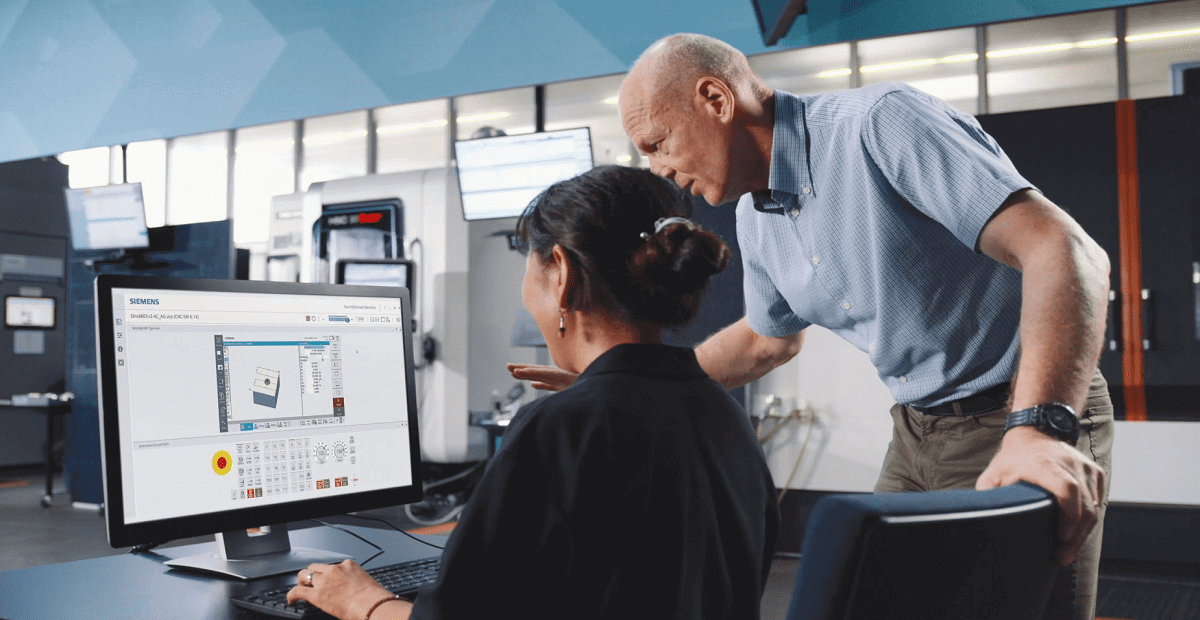

Digital twins of machine tools

Digital twins of machine tools play a major part in optimizing the machine manufacturer's engineering processes. This is because the digital twin in the automation environment makes it possible to execute process steps in parallel, as opposed to consecutively, as used to be the case.

Administration for Digital Industries, moda

Product Description :

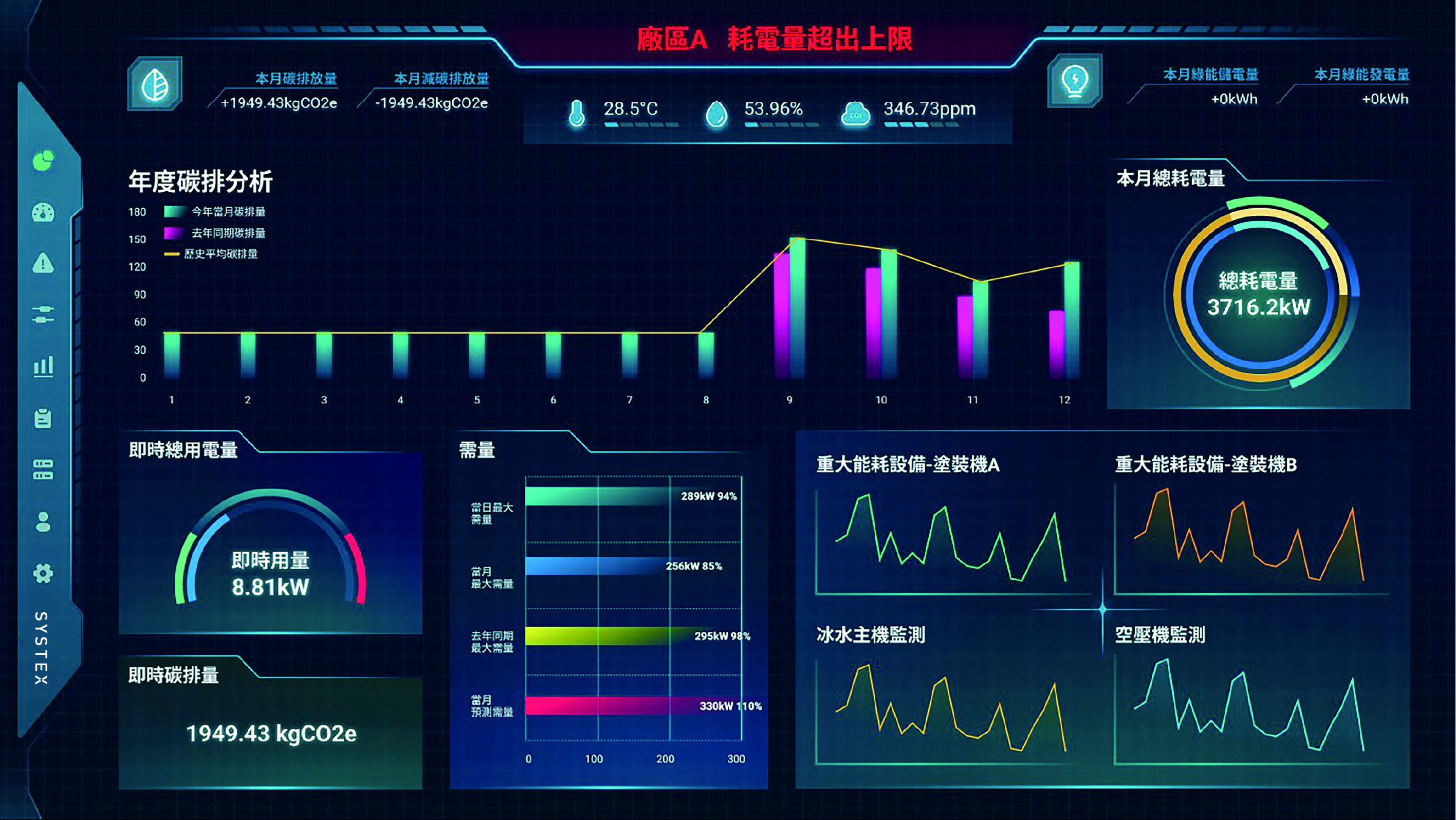

Taifon Computer Co., Ltd. provides the EnVision360 Energy Management Platform, enabling real-time electricity monitoring, that helps users monitor demand response and detect electrical anomalies through data visualization with power consumption trends.

By utilizing this cloud-based energy management platform in conjunction with smart meters, it is possible to establish energy baselines, calculate energy efficiency index, and effectively manage energy consumption with ease.

Administration for Digital Industries, moda

Product Description :

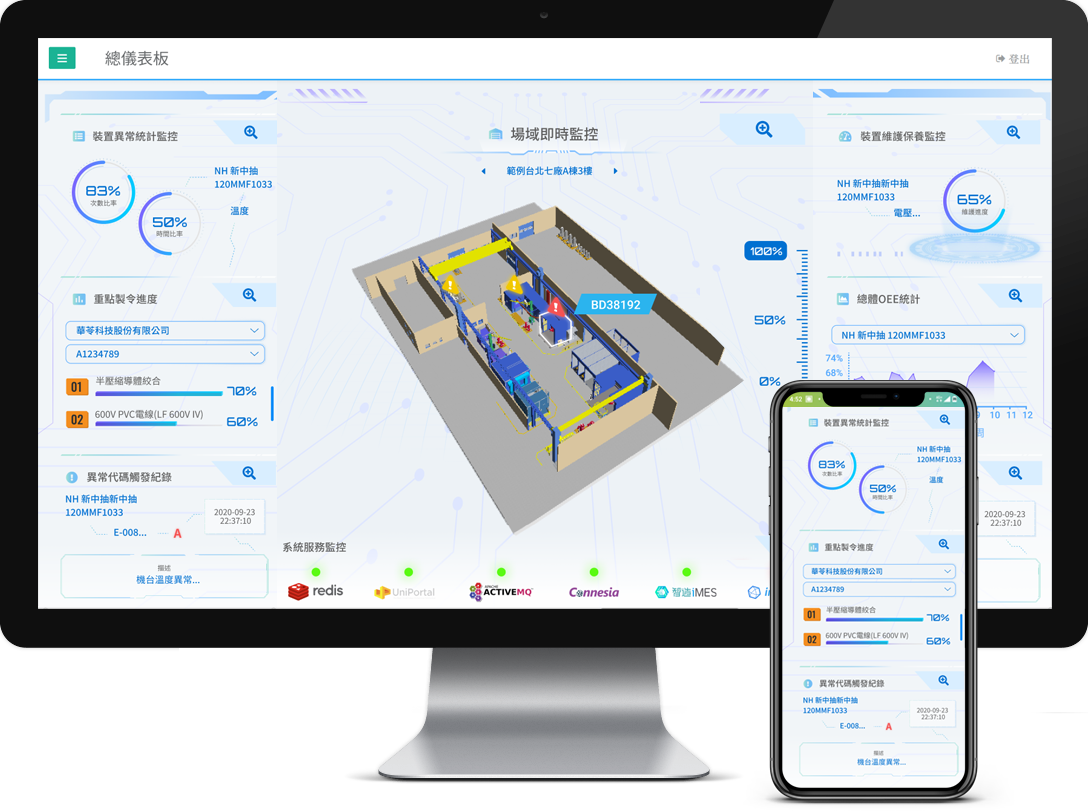

iMES's real-time Internet of Things and monitoring reports gradually achieve smart manufacturing remote monitoring, providing each manufacturing customer with six major capabilities, including real-time collection of production data, working hours management, exception notification, intelligent management of production lines, optimization of production schedules, etc. Intelligent production applications realize automated and efficient interconnected factories.

1. Arrange optimal production schedule.

2. Generate ERP work orders.

3. Automatically manage machine recipe parameters.

4. Two-way real-time control of the machine device.

5. Manage the triggering rules for subsequent tasks on the machine.

6. Automation machine completion report information.

DOWELL CO.,LTD.

Product Description :

ESPRIT® is a high-performance CAM system for CNC programming, optimization and simulation — supporting any class of CNC machine via one common user interface and workflow. Using a digital twin of the CNC to simplify the programming process, ESPRIT delivers edit-free G-code. Combined with ESPRIT's ability to solve workflow challenges with individually tailored automation solutions, ESPRIT is the smart manufacturing solution for any machining application.

With world-class technical support, ESPRIT empowers you to get started quickly and keep your shop running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

Administration for Digital Industries, moda

Product Description :

AEAPLUS Smart Factory empowers you to create the ultimate production workflow!

Highlights include:

MES System: Intelligently manage production for enhanced efficiency!

B2B Solutions: Simplify supply chains, expedite order processing!

WMS System: Precise inventory management, cost-saving!

PSRA Assistant: Smart scheduling for automated production!

PDM Management: Optimize product data for improved performance!

QRM Quality Records: Elevate quality control, continual optimization!

BI Analytics: Data insights for informed decision-making!

RPA Automation: Streamline workflows, unleash manpower!

Irrespective of your factory's scale, our solutions deliver tangible benefits, aiding you in achieving more efficient and intelligent production processes.

SGCAM TECHNOLOGY CO., LTD.

Product Description :

國內市佔率最高的CNC車床CAD/CAM軟體<br />

全中文畫面,簡單易學、繪圖快速,最符合加工業使用的CAD/CAM軟體<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

3D動態實體切削模擬,可預先檢視切削路徑避免刀具干涉及過切。<br />

可設定架刀的安全角度,減少刀刃整面接觸工件而抖動,使刀具壽命延長。<br />

自動檢查、過濾、斷線、刪除重疊線段。<br />

準確的計算加工時間和工件重量,給予客戶精確的報價訊息,即時的爭取客戶的信任與訂單,決解你接單報價的困擾。<br />

支援完整切削複合循環功能G71、G72、G74、G75(不規則形狀也可使用G75) 。<br />

智慧型沿輪廓加工,節省加工時間(G73改良型) 。<br />

智慧型自動挑刀、斷屑、分層,直線、圓弧皆可自動做斷屑或暫停的動作,再也不用為斷刀而傷透腦筋了。<br />

人性化的刀庫設定,可依每位使用者設定不同的常用刀具。<br />

可做特殊造型螺紋切削、連續螺紋多牙嘴 。<br />

刀具路徑圖形化,刀具路徑也可直接作編修,編修完成G碼立即更改。<br />

弧長、角度、斜度比自動換算功能。

SGCAM TECHNOLOGY CO., LTD.

Product Description :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

參數式的加工資料設定,作CAM只需三個步驟:(1)選擇工法(2)指定加工參數(3)計算、轉出加工G碼。<br />

參數式的資料設定,圖形改變後,加工碼會自動隨之改變。<br />

智慧型功能:<br />

工法和加工的輪廓可直接複製修改,不必再重新指定。<br />

自動清角可自動清除前一把刀具,所留下來的角落殘料。<br />

鑽孔時依據孔徑大小,自動搜尋鑽孔的加工位置,不必每一孔都去點選指定。<br />

字型可自動截割輪廓外圍不用慢慢編修。<br />

支援單筆劃字型刻字。<br />

加工路徑最佳化,各加工路徑間依最短距離自動計算,且可指定各加工路徑間不提刀以縮短加工時間,達到最佳之加工效率。<br />

立體加工: 不必畫3D曲面圖形就可做出立體加工工法,簡單夾治具可自行製作。<br />

牽引面加工:可加工彎管、簡單的立體。<br />

規則面加工:規則斜面、四角錐面、圓錐面。<br />

旋轉面加工:圓球面、葫蘆形狀。<br />

Z軸投影加工:可在不等高的平面上作投影加工。