Theme

Digital Transformation

Green Transformation

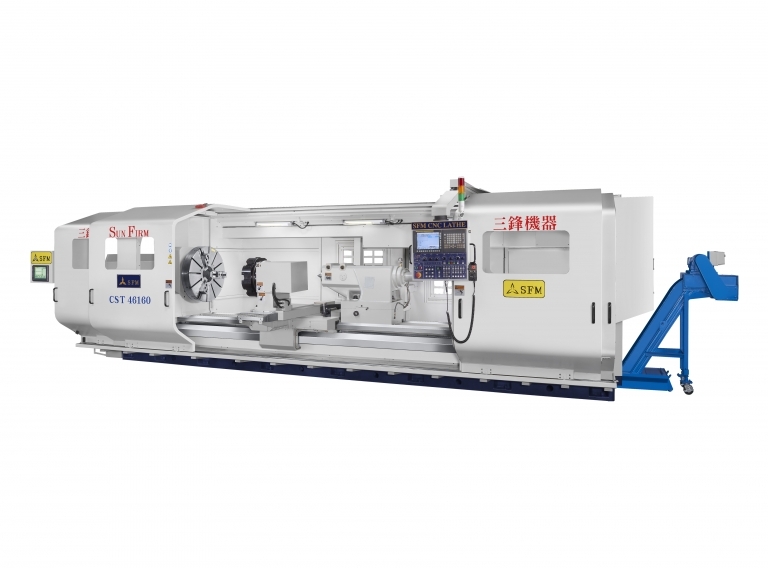

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

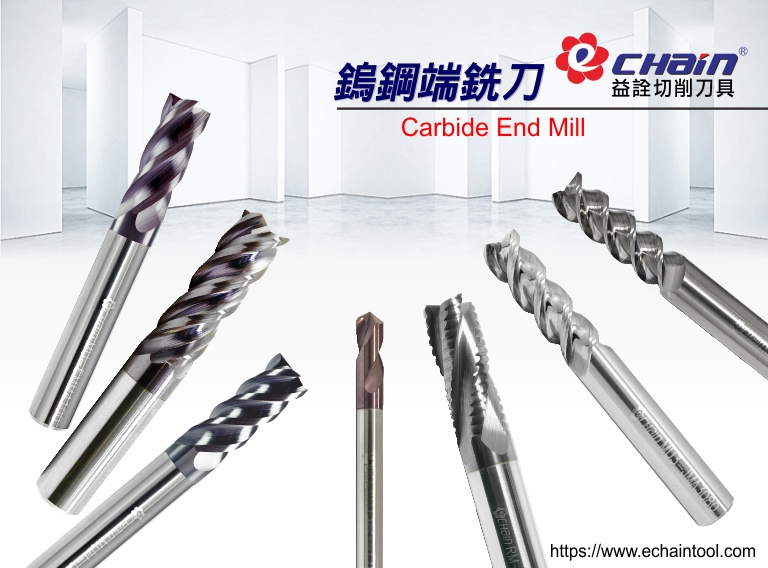

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

主軸箱 <br />

全部齒輪及槽軸都用合金鋼製成<br />

經滲碳處理及精密研磨。 <br />

旋轉式變速機構操作簡單。<br />

<br />

齒輪箱 <br />

全能車製螺紋機構,任意車製。 <br />

公制螺紋、英制螺紋、模數螺紋、<br />

徑節螺紋,不需變換齒輪。<br />

<br />

床身 <br />

高剛性之肋骨結構。 <br />

3V床軌設計,精度永保如新。 <br />

高精度寬大床面、經淬火並研磨。 <br />

一體成型落地底座適合重型工件並延長使用年限。<br />

<br />

兩頂心距離 <br />

全系列兩頂心多300mm可實際車<br />

削更長工件。<br />

<br />

尾座 <br />

軸承支撐,移動輕便。<br />

<br />

護床 <br />

滑座與床鞍加長加寬,重切削更強。 <br />

調整容易的超負荷安全裝置。<br />

SPINDLE 配有潤滑油手動和自動雙重潤滑給油系統。 <br />

<br />

主軸 <br />

超大直徑主軸,主軸孔徑153mm,230mm(OPT)。 <br />

超精密軸承三點支持式。<br />

<br />

快送及自動跳脫 <br />

自動縱向可任意控制跳脫距離,有縱向及橫向<br />

快送選擇。<br />

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

PJ-20V0 is a surprising design. In addition to the dead corners of the bar feeder, there are also many spaces that easy to ignore, used by customers to pile up the stuff and lose the value of use. The idea of PJ-20V0 revitalizes these spaces and is no longer limited to 2D imagination, also to evolve to the concept of 3D space. This system provides a powerful and compliant function system for users continuously. Using for continuous variable volume (pressure), saving the electricity cost and the time of the adjusted pressure. Suitable for the Swiss Lathes and gun drilling.

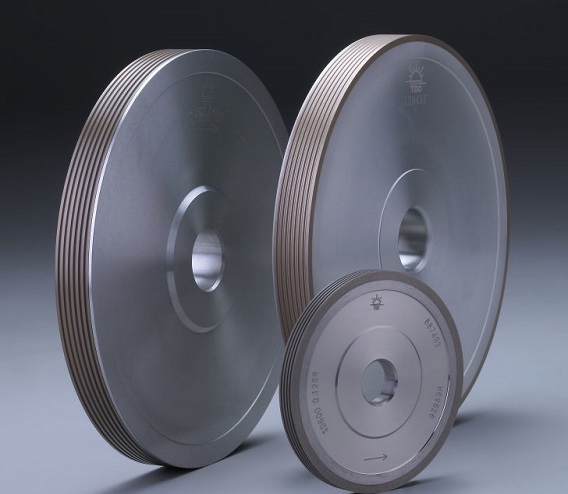

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Semiconductor Material Processing

* Silicon wafer edge grinding wheels require strict shape precision and wear resistance, and require stable grinding capabilities, so metal bond grinding wheels can be used. We can provide single groove or multi groove, integrated coarse and fine grinding wheel according to customer’s requirements.

* Processing Material | Silicon Crystal

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The WTS series combine with double turret, double spindle and double Y axis. Both of 16-station power turrets are available to be equipped of BMT-55 tooling system. The WTS has E-axis shifting function, it allows the sub spindle to move up and down to provide independent working area.

The WTS-52Y2M provide ∅51mm maximum bar feeding dia. and it can install fixed tailstock above the sub spindle when using collet, it allows to keep the longer workpiece dynamic balance with the main spindle and improves precision during machining. The WTS-65Y2M bar capacity up to ∅65mm, the A-6 spindle nose can install larger size chuck and the spindle motor upgrade to higher torque and bigger power.