Theme

Digital Transformation

Green Transformation

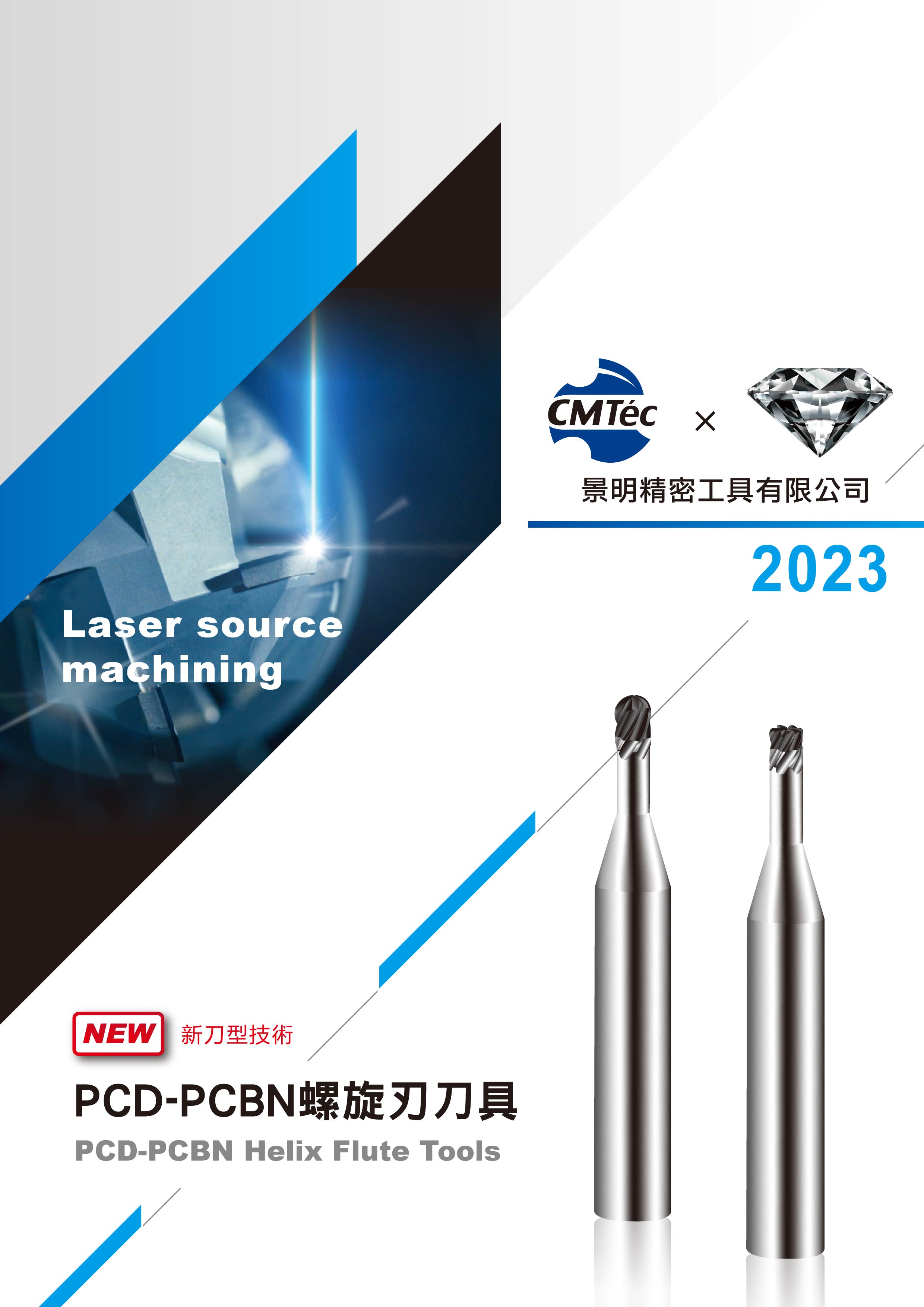

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.

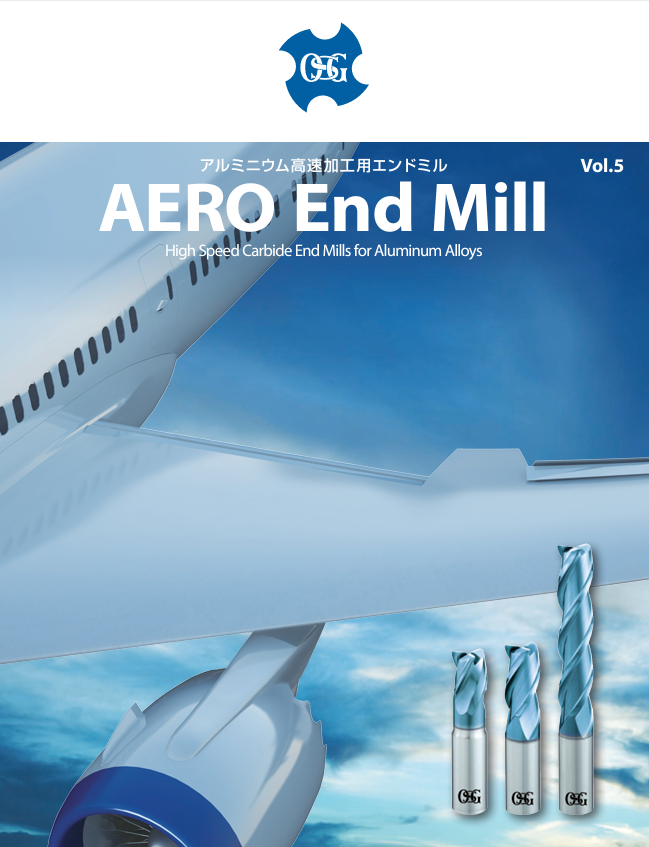

TAIHO TOOL MFG. CO., LTD.

Product Description :

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.

VISION WIDE TECH CO., LTD.

Product Description :

• Patent design high-pressure coolant system up to 125 bar

• Turning 75Kw

• Vertical milling

• Grinding

• Turning-Milling ATC

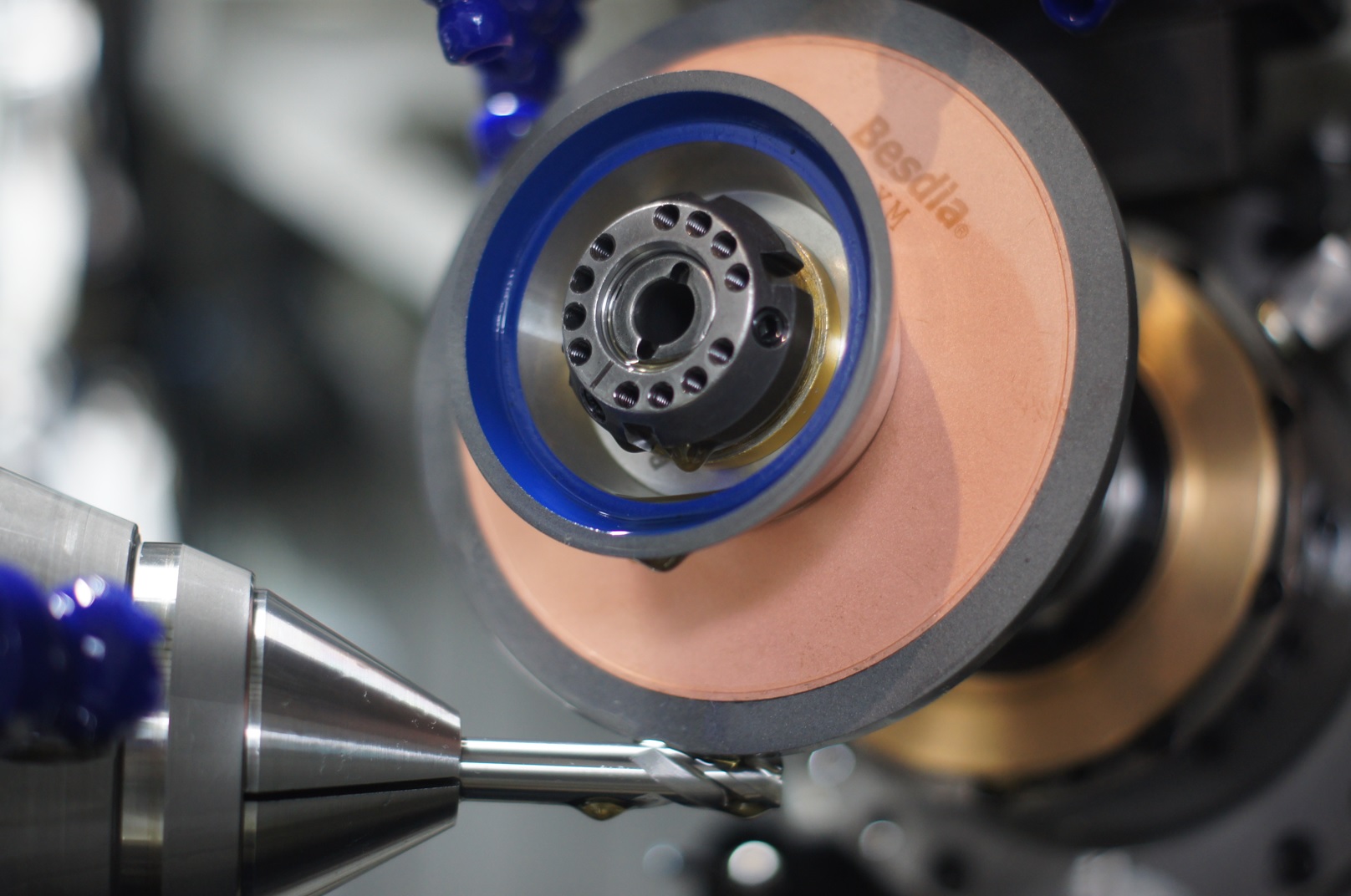

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

●Internal and external threading for both left-thread and right-thread with one tooling

●Safe machining operation and easier to reach the bottom inside the blind holes

●Evacuate the chip more efficiently than the traditional milling process. shank: 20mm~40mm , Internal Thread Insert: 12I , 14I, 21I, 30I , 40I , External Thread Insert: 14E, 21E, 30E , 40E

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

Heat-treated steel

Coolant design

Perfect 90° milling

High number of teeth, increased productivity

PTN10-cutting depth up to 5mm

PTN16-cutting depth up to 10mm

PTN16-the clamping screw is enlarged for easier locking and greatly improved stability

The unique design of low cutting resistance can better machining continuity, achieve milling of 90°, and get a perfect machining surface.

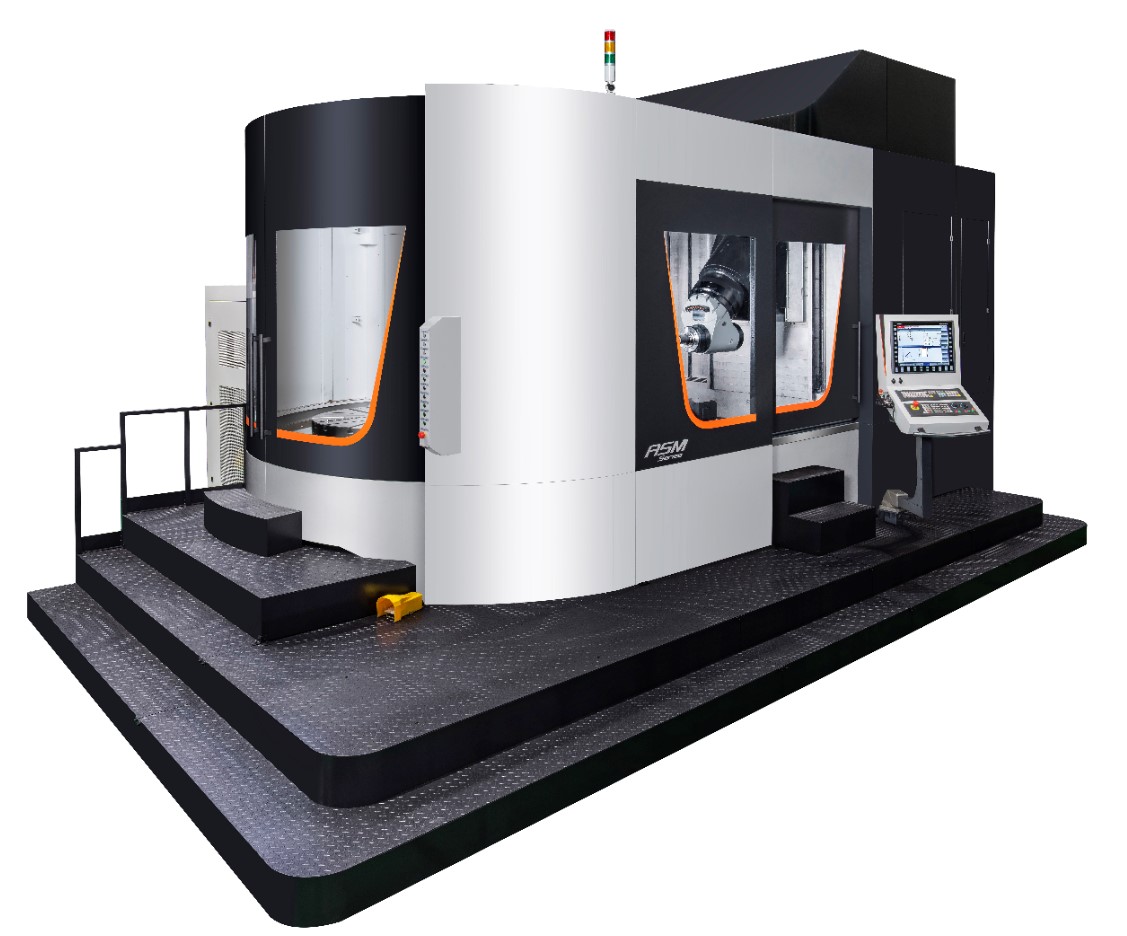

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.