Theme

Digital Transformation

Green Transformation

7-LEADERS CORP.

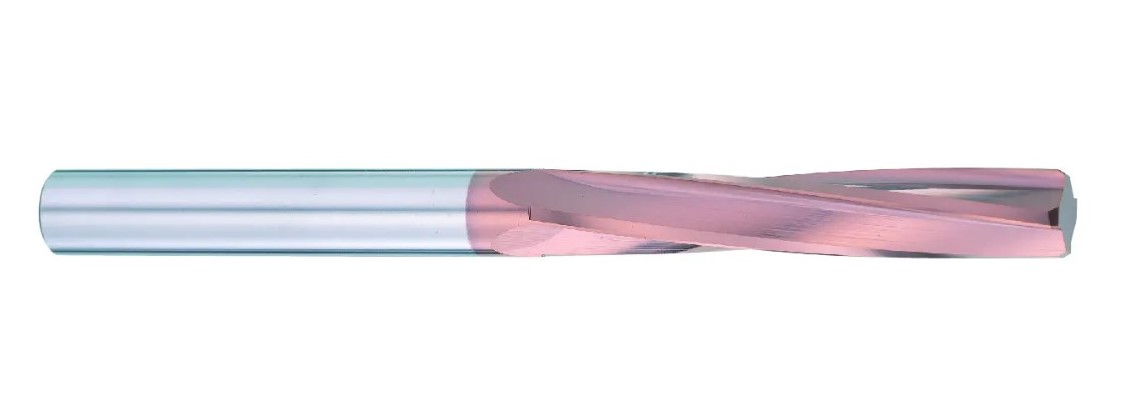

Product Description :

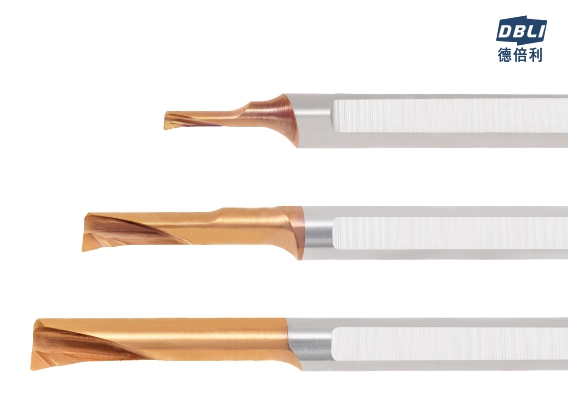

Designed with left helix and right cutting flutes with unequal flute design.

Downward chip evacuation.

Application for reaming different steels below 62HRC, stainless steel, High temp alloys, cast iron, copper…and etc.

Extremely high reaming life with coolant holes for blade cooling.

Nano multilayer coating AlTiSiN with superior wear resistance is suitable for high hardness materials reaming.

Accuracy tolerance: H7 (m5)

0/+0.004mm

TAIHO TOOL MFG. CO., LTD.

Product Description :

The blade design that emphasizes cutting force and the unequal lead groove shape promote chip discharge and realize high-quality threading.

The lineup includes screw type for blind holes and through holes, and features that chips are discharged upwards.

The tip sample is for through holes, and the characteristic is that the chips are discharged downward.

There are two types of pipe specimens: parallel thread for mechanical bonding and tapered thread for tightness.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

● low resistance to prevent vibration and works efficiently

● Various applications for profiling, ramping, and face milling.

● with many cutting edges to save the cost

● Precision coolant design enhances the insert life

diameter: 16mm~50mm

CHIN MING PRECISION TOOLS CO., LTD.

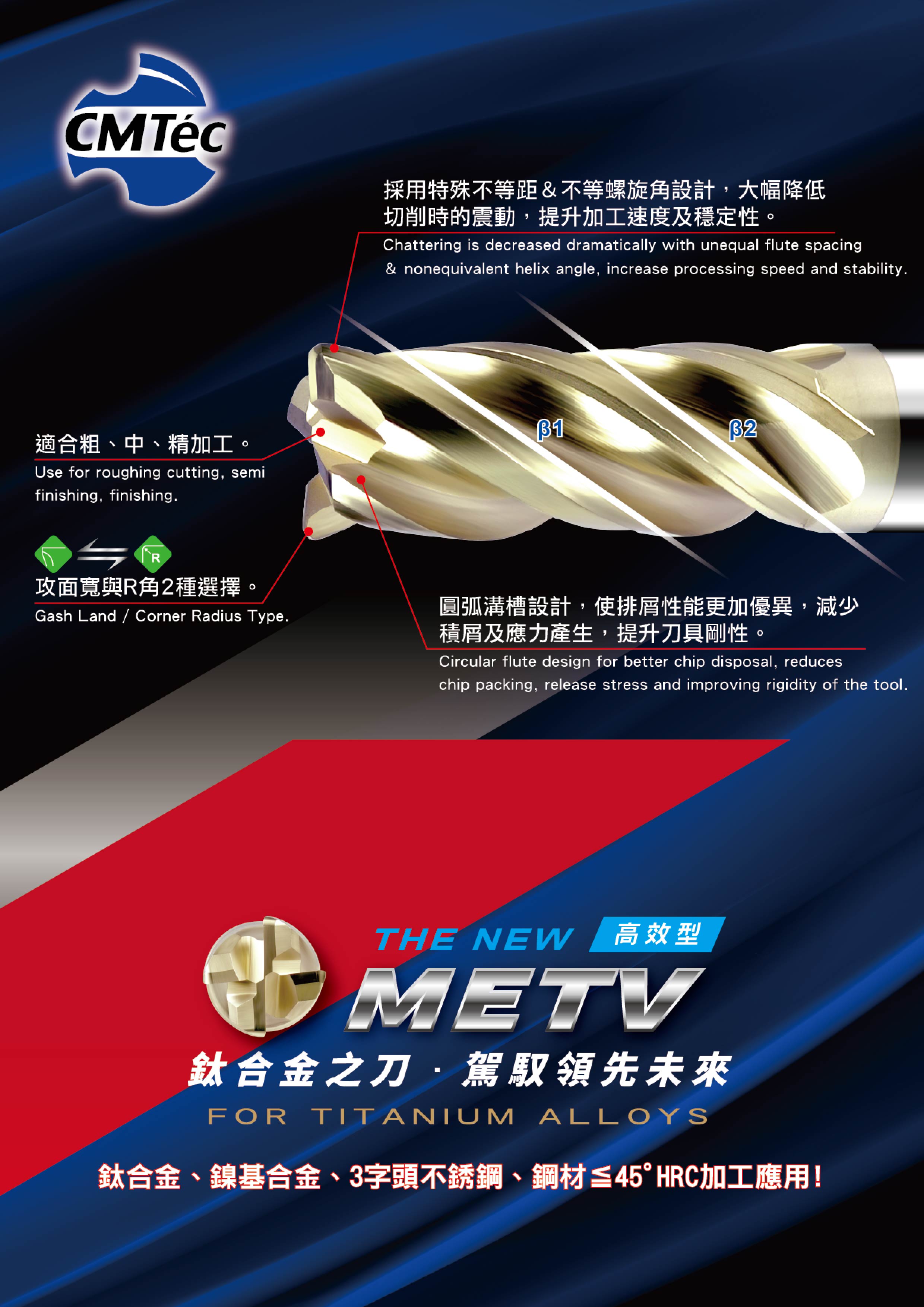

Product Description :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

LEADRANK CO., LTD.

Product Description :

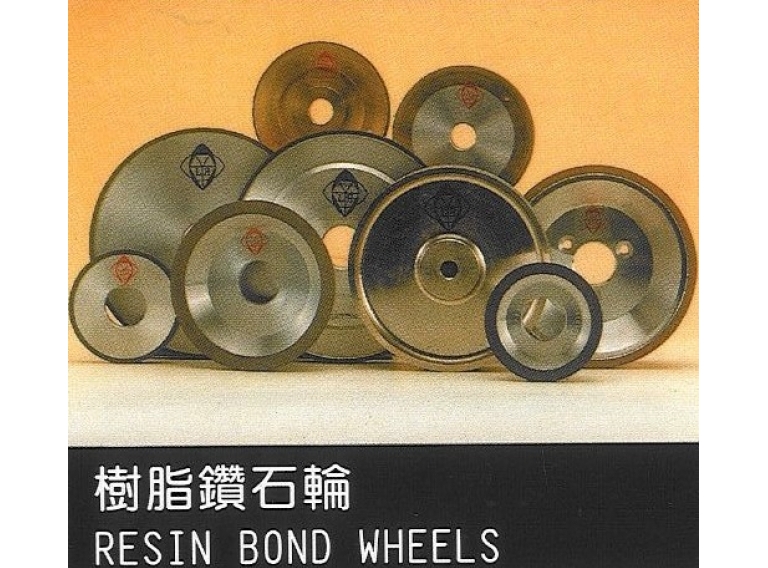

●樹脂結合法為採用酚醛樹脂或高溫樹脂這類熱固型樹脂較軟且富有彈性;自銳性及研磨性能佳,研磨時不易產生工件燒焦現象,因樹脂砂輪製品具有彈性可以減少加工時的破壞力,進而使得加工面較為精細!

●而鑽石通常應用在:碳化鎢、玻璃、陶瓷、氧化鋁、碳化矽

●CBN則是應用在:1.工具鋼:切割刀具、刀具、拉絲模、鋸片...等。 2.合金鋼:齒輪、軸、閥杆刀片、航空零件、不鏽鋼、鑄鐵。

LIN PONG TRADING CO., LTD.

Product Description :

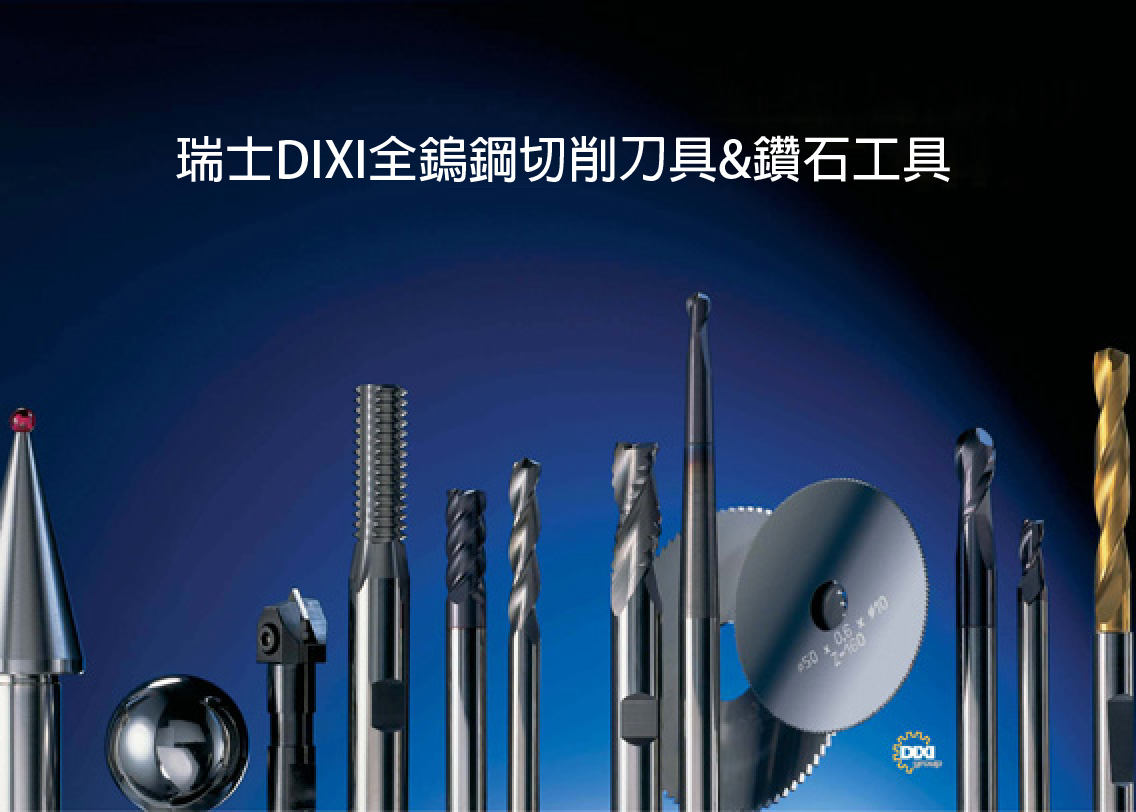

由瑞士DIXI POLY公司生產製造的全鎢鋼立銑刀、球刀、圓鼻刀、<br />

銑牙刀、鑽頭、中心定位刀、倒角刀、丸鋸片、鑽石刀具...等產品,<br />

是高精密加工不可或缺的生產工具。

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

VISION WIDE TECH CO., LTD.

Product Description :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

JIMMORE INTERNATIONAL CORP.

Product Description :

- 功率: 13KW

- 電壓: 3 相/400~480V,16A

- 適用刀具: 直徑: Ø3~32mm 的碳化鎢和高速鋼

- 最大刀長 : 570 mm

- 線圈 : 高效能新一代燒結線圈, 只需調整刀具尺寸,

不需更換刀具定位環∘

- 三孔迴旋式刀具座

- 含接觸式高效率冷卻機與冷卻水套

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. With excellent features of coating to increase the tool's wear resistance and thermal conductivity to reduce the chip residue problem.

2. Use special flute design to decrease the chip-off problem during machining.

3. Increase machining accuracy and surface roughness.