Theme

Digital Transformation

Green Transformation

MATRIX PRECISION CO., LTD.

Product Description :

Matrix (Formed as Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (Formed as Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (Formed as Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

Our grooving tool and parting-off tool holders are both used with the indexable carbide insert. The selection is determined by the width and depth of the groove and parting-off.shank: 10mm~32mm . cutting width: 2mm~5mm

7-LEADERS CORP.

Product Description :

Designed with left helix and right cutting flutes with unequal flute design.

Downward chip evacuation.

Application for reaming different steels below 62HRC, stainless steel, High temp alloys, cast iron, copper…and etc.

Extremely high reaming life with coolant holes for blade cooling.

Nano multilayer coating AlTiSiN with superior wear resistance is suitable for high hardness materials reaming.

Accuracy tolerance: H7 (m5)

0/+0.004mm

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

DEEP JET INDUSTRY CO., LTD.

Product Description :

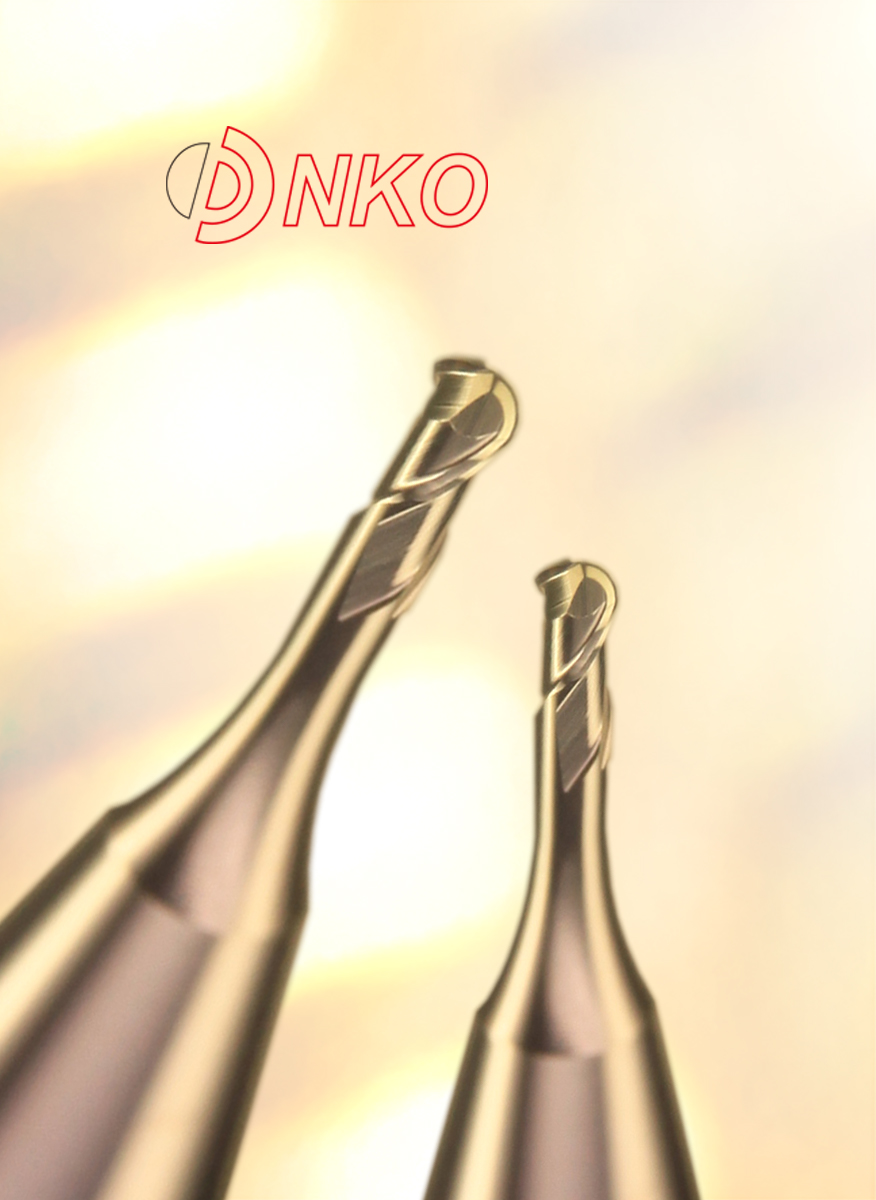

1.Special cutting-edge design with low resistance to reach better chip-off from the groove. This shows the tool's stability in high speed machining.

2.The special coating enhances the anti-oxidation and wear resistance to increase high speed performance.

◆Carbide Drills With Internal Coolant Holes:

Internal coolant holes can highly increase the performance of cooling and chip removal rate.

◆Carbide Flat Drills:

Good for curve and inclined surface machinning.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

Heat-treated steel

Coolant design

Perfect 90° milling

High number of teeth, increased productivity

PTN10-cutting depth up to 5mm

PTN16-cutting depth up to 10mm

PTN16-the clamping screw is enlarged for easier locking and greatly improved stability

The unique design of low cutting resistance can better machining continuity, achieve milling of 90°, and get a perfect machining surface.