Theme

Digital Transformation

Green Transformation

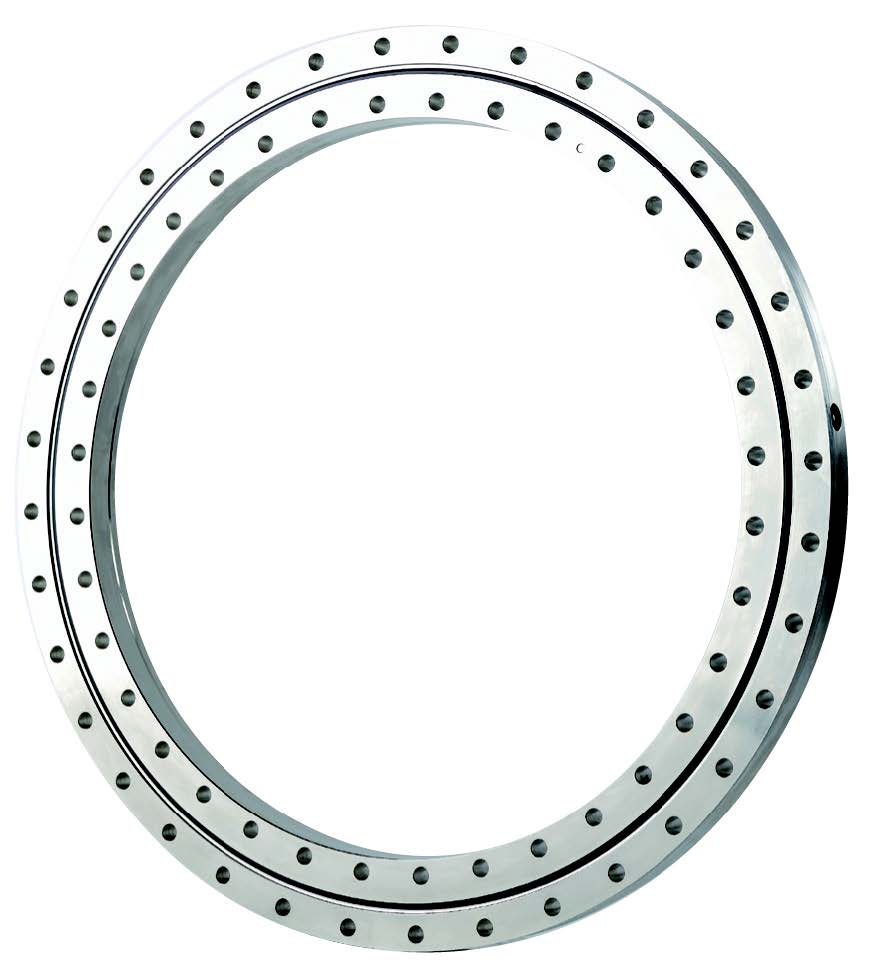

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.

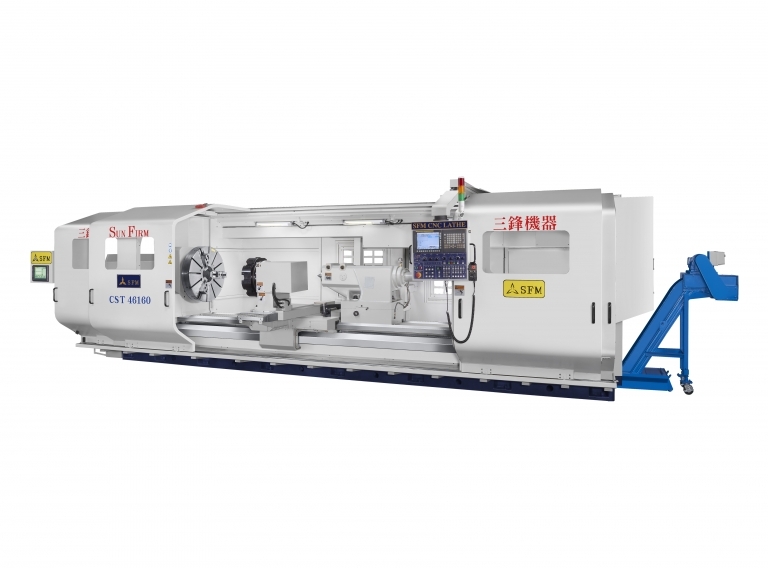

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.

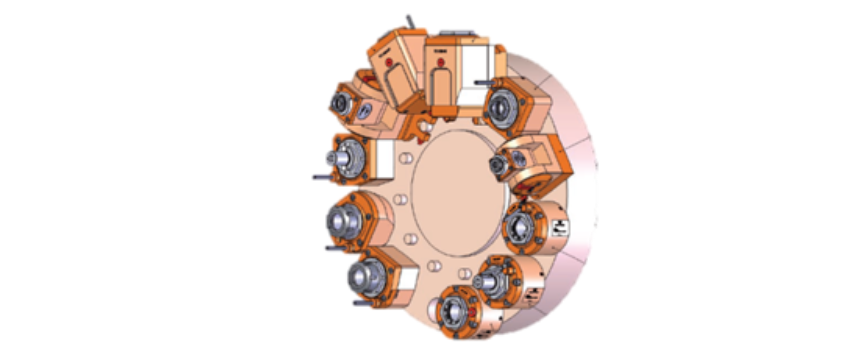

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.