展览主题

数位转型

绿色转型

AUTOMAZIONI INDUSTRIALI SRL

产品描述 :

The FT 7100 AP model features:

- 3 horizontal extruders (full-electric) + 1 adjustable extruder from 0 to 45 degrees. Special extruder to forge Y valves.

- 260 Tons forging capacity

- 107mm stroke

- energy consumption: max. 35 kW/h

- productivity: 4500 parts per hour

- cycles per minute: 24/25 depending on the type of part

- size of parts: up to 2''; 4 kg

- burr-free forging

With FORGE TRONIC presses you can produce a wide range of parts including:

• Heating system fittings: HVAC fittings,fittings for gas applications, radiators and central heating fittings, gas plumbing,

• Fittings for water supply: water meters, water plumbing, plumbing fittings, valves for water (ball o gate valves for water, elbows, Tee fittings, water intake, plumbing, strainers)

• Fittings for hydraulics

• Fittings for pneumatics

- ELECTRIC TECHNOLOGY:

All the axes, the upper die, the four extruders and the unloading arm are directly driven by electric motors, allowing the user to regulate and monitor the process variables: position, speed, torque, etc. Thanks to a touchscreen monitor, the operator can set up the work cycle, the stroke, start and end parameters for each extruder.

This way, the press is so accurate and precise that the forged parts have no burrs after forging and do not need any extra machining.

The press has an integrated die lubrication through 16 upper nozzles and 16 lower nozzles and the required oil volume can be adjusted directly through machine settings.

A specific Cad-Cam software allows the import of Step files of the die, workpiece, pins and pin bushings and other relevant settings can be saved, such as the start/ stop sequences of the pins. In addition, the software enables the operator to emulate the machine cycle and then the relevant file can be transferred directly to the Forge Tronic press. The press is available in different versions in order to meet the needs of different customers and reach various machine throughputs.

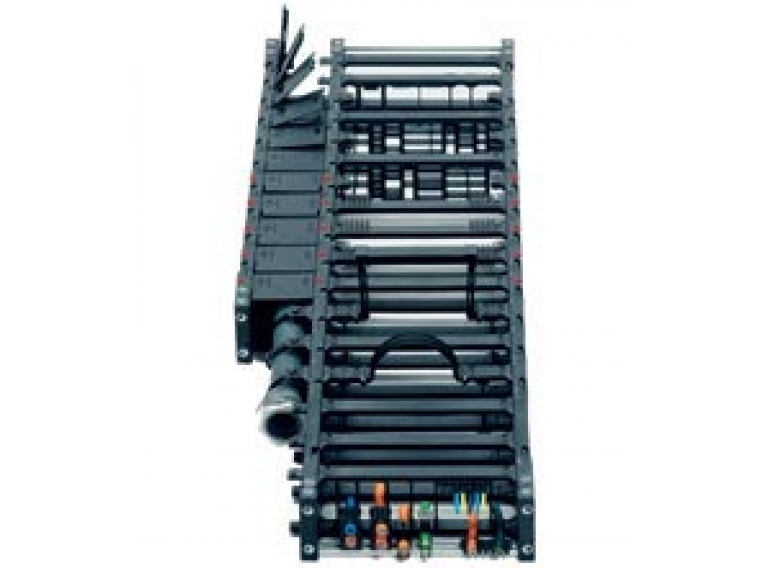

台灣易格斯有限公司

产品描述 :

●拖鏈系統<br />

根據拖鏈類型預先選擇<br />

V高性價比,易於裝填的拖鏈,一片式,拉鏈式<br />

V極小,小及中型尺寸拖鏈,一片式和兩片式<br />

V防護電纜不受碎屑和污垢的影響 - 用於能量供應系統的拖管,兩片式<br />

V幾乎適用於所有應用的標準四片式拖鏈套件<br />

V低噪音,低磨損,無震動的三片式或六片式拖鏈<br />

V適用於3維和圓周運動的拖鏈,尤其適用於機器人應用<br />

V長行程拖鏈和特別應用的拖鏈解決方案。<br />

V浪管和軟管導向解決方案<br />

<br />

●用於移動供電的chainflex®<br />

用於移動供電的 chainflex® 耐彎曲電纜<br />

chainflex® 耐彎曲電纜是非訂製電纜,用於拖鏈中的運動應用或機器手臂應用,保證36個月無故障。 <br />

chainflex® 耐彎曲電纜符合EMC安全要求以及各種標準和準則,如UL、CSA、VDE、EAC、CTP、Interbus和Profibus。 c可採用多種護套材質。產品系列涵蓋了控制電纜、伺服電纜、馬達電纜、機器人電纜,以及總線電纜、數據電纜、編碼器電纜和光纖電纜。用於拖鏈的 chainflex® 耐彎曲電纜在長時間內完美運轉,承受眾多循環、高速和高加速度以及非常極端的環境條件。<br />

<br />

●訂製電纜 readycable®<br />

readycable® 全裝配電纜是適合在拖鏈中使用的易於連接的電纜。作為製造商和訂製廠商,igus® 從單一來源提供所有產品,從而減少生產時間和供應商的數量。產品組合包含廣泛的目錄產品系列,如根據製造商標準和不同工業標準訂製的電纜以及單獨或量產的部件。許多不同質量、不同類型、符合不同標準、不同認證的電纜可供選擇。所有部件都接受廣泛的品質檢查和功能測試。<br />

<br />

●組裝到好的 readychain®全裝配拖鏈<br />

客製的拖鏈系統:精簡從設計到組裝的流程<br />

我們即插即用的客製拖鏈可將採購選項、零件清單項目、聯絡人數量和安裝工作量降至最少。 這樣以避免不必要的倉儲空間和資源浪費。 它們創造出最佳的解決方案並增加加您的競爭優勢。 它們優化了拖鏈、電纜、接頭、空壓管、液壓管、金屬件、傳感器、PLC、軸承、線性滑軌裝置和其他機械零件的供應鏈。 <br />

拖鏈、電纜、模組化——以 igus® 的全裝配拖鏈優化流程!<br />

<br />

更多資訊: https://www.igus.com.tw/