展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

ACCUTEX TECHNOLOGIES CO., LTD.

製品の説明 :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

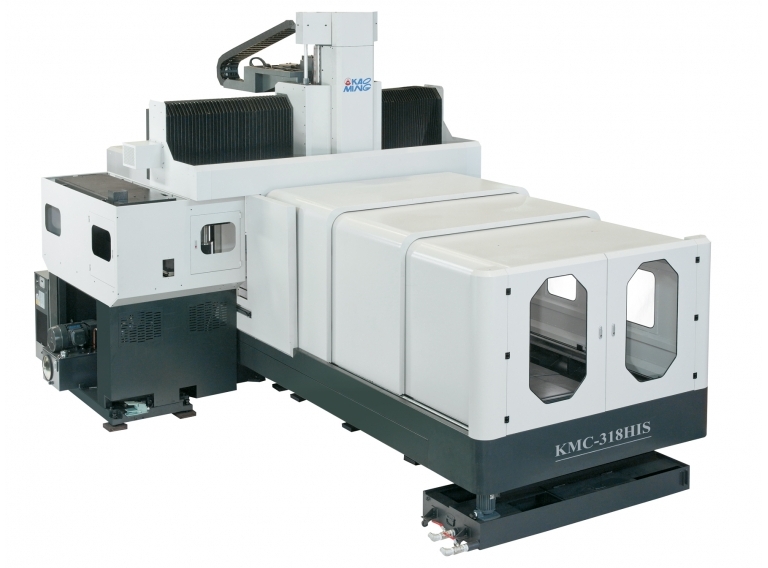

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />

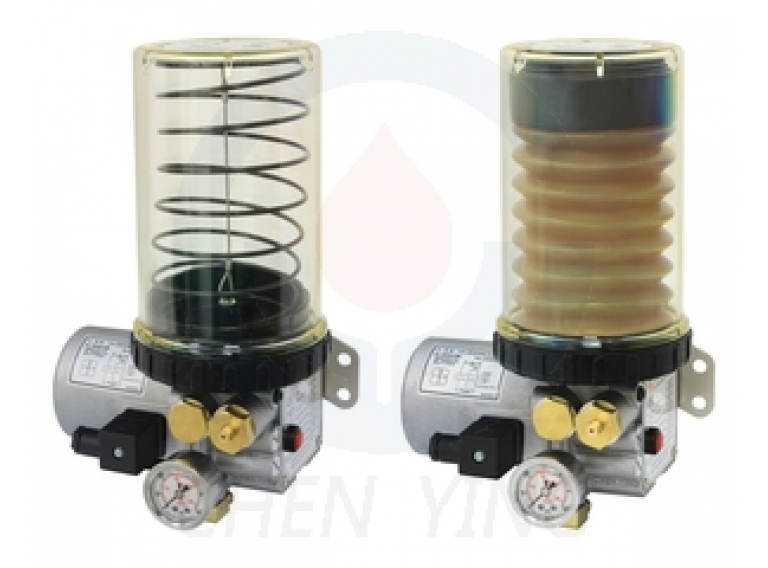

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

製品の説明 :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.

Administration for Digital Industries, moda

製品の説明 :

AEAPLUS Smart Factory empowers you to create the ultimate production workflow!

Highlights include:

MES System: Intelligently manage production for enhanced efficiency!

B2B Solutions: Simplify supply chains, expedite order processing!

WMS System: Precise inventory management, cost-saving!

PSRA Assistant: Smart scheduling for automated production!

PDM Management: Optimize product data for improved performance!

QRM Quality Records: Elevate quality control, continual optimization!

BI Analytics: Data insights for informed decision-making!

RPA Automation: Streamline workflows, unleash manpower!

Irrespective of your factory's scale, our solutions deliver tangible benefits, aiding you in achieving more efficient and intelligent production processes.

Parjet Co.,Ltd.

製品の説明 :

Parjet has become a leader in the sealing industry by providing a full range of sealing solutions. For every complex seal application, Parjet has a solution.

Mechanical shaft seals are often an ideal sealing method. They provide the most suitable sealing method under many conditions especially high temperatures, high pressures, high viscosity (sediment), high speeds, large diameters, and many others. Most importantly, we have a highly technical mechanical seal providing and customizing the most optimal sealing solution for you.

GP MACHINERY CO., LTD.

製品の説明 :

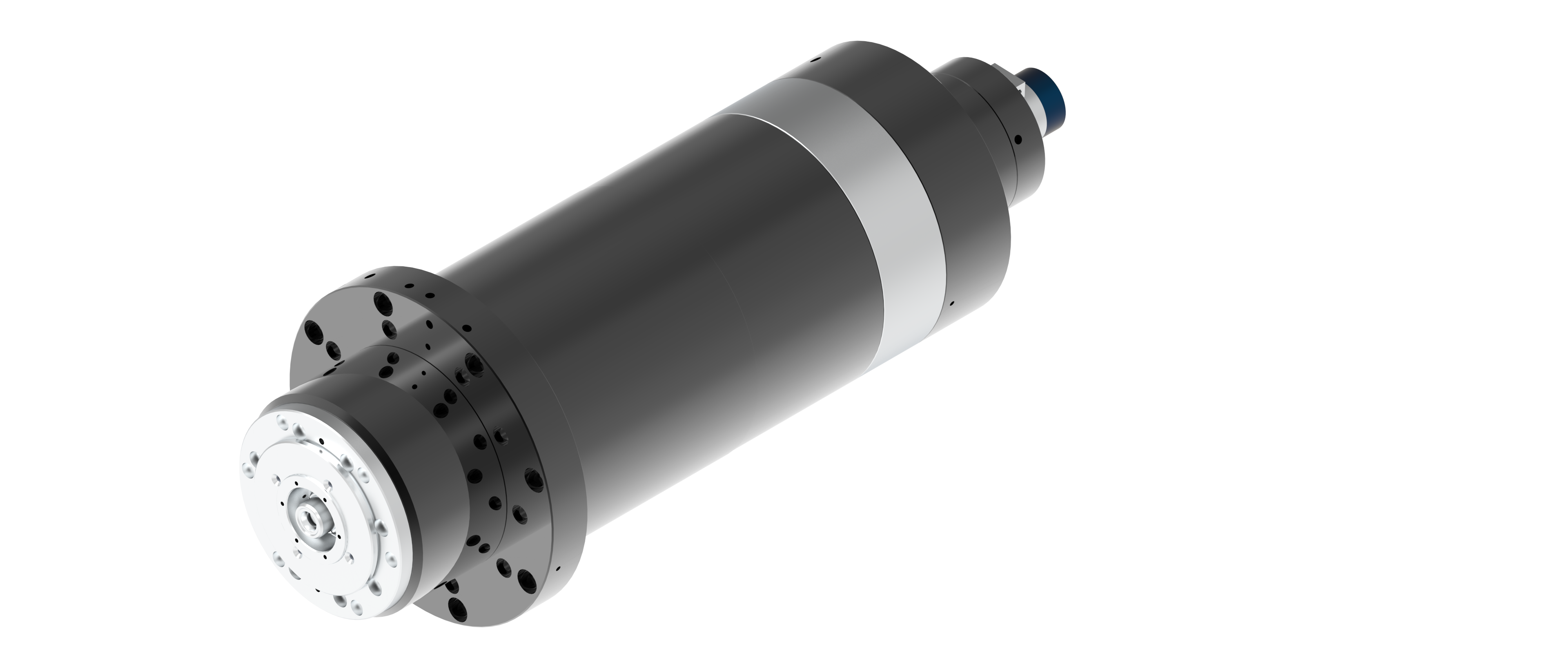

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.