展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

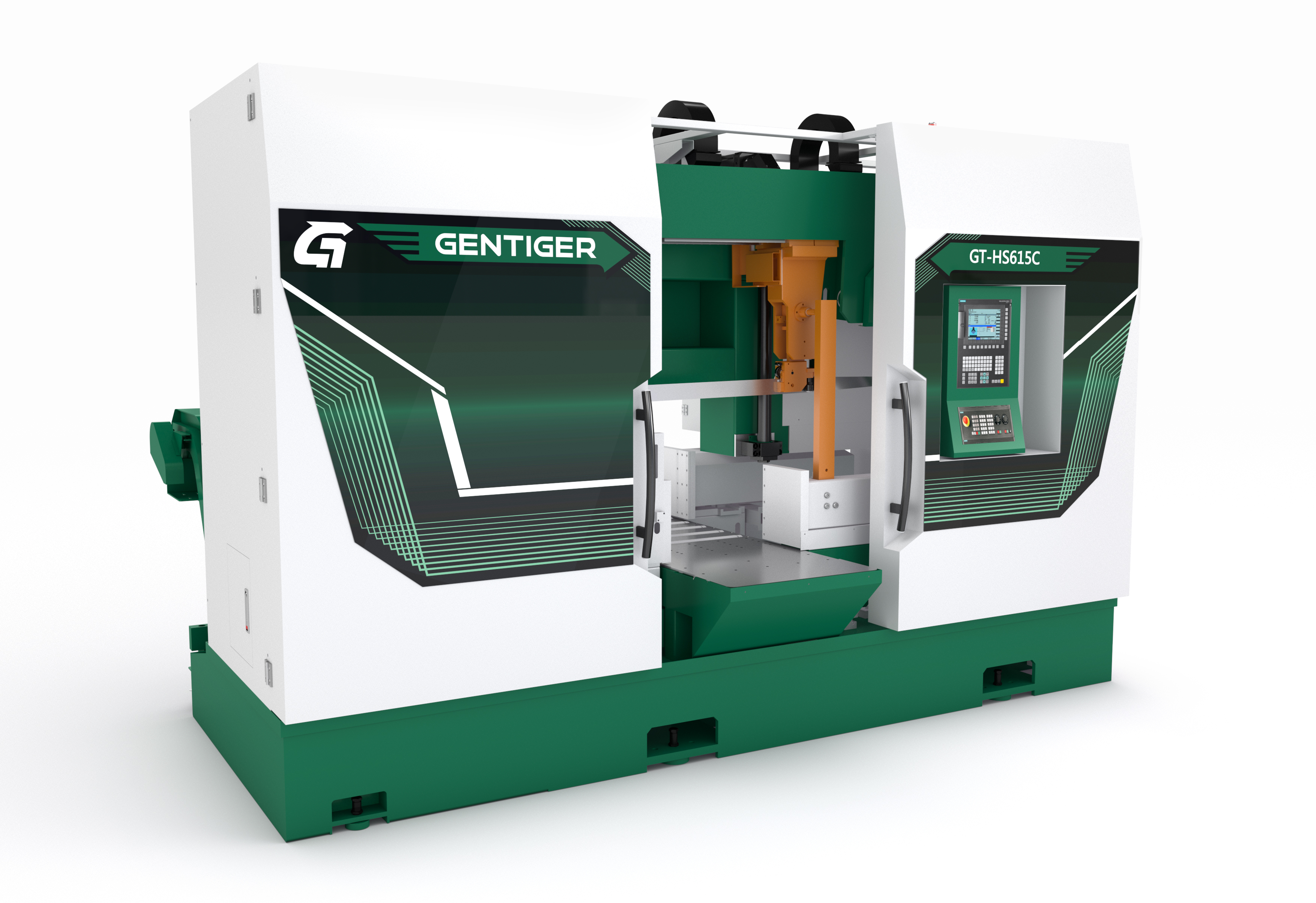

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

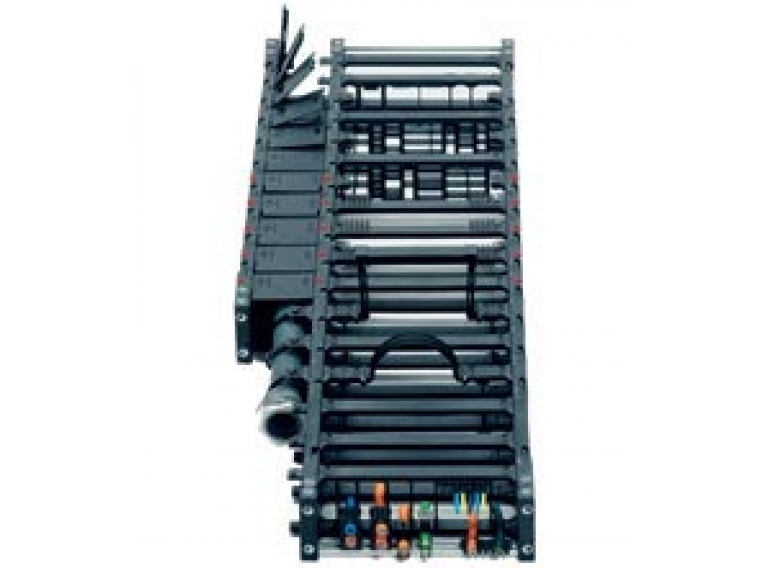

IGUS TAIWAN COMPANY LTD.

製品の説明 :

●拖鏈系統<br />

根據拖鏈類型預先選擇<br />

V高性價比,易於裝填的拖鏈,一片式,拉鏈式<br />

V極小,小及中型尺寸拖鏈,一片式和兩片式<br />

V防護電纜不受碎屑和污垢的影響 - 用於能量供應系統的拖管,兩片式<br />

V幾乎適用於所有應用的標準四片式拖鏈套件<br />

V低噪音,低磨損,無震動的三片式或六片式拖鏈<br />

V適用於3維和圓周運動的拖鏈,尤其適用於機器人應用<br />

V長行程拖鏈和特別應用的拖鏈解決方案。<br />

V浪管和軟管導向解決方案<br />

<br />

●用於移動供電的chainflex®<br />

用於移動供電的 chainflex® 耐彎曲電纜<br />

chainflex® 耐彎曲電纜是非訂製電纜,用於拖鏈中的運動應用或機器手臂應用,保證36個月無故障。 <br />

chainflex® 耐彎曲電纜符合EMC安全要求以及各種標準和準則,如UL、CSA、VDE、EAC、CTP、Interbus和Profibus。 c可採用多種護套材質。產品系列涵蓋了控制電纜、伺服電纜、馬達電纜、機器人電纜,以及總線電纜、數據電纜、編碼器電纜和光纖電纜。用於拖鏈的 chainflex® 耐彎曲電纜在長時間內完美運轉,承受眾多循環、高速和高加速度以及非常極端的環境條件。<br />

<br />

●訂製電纜 readycable®<br />

readycable® 全裝配電纜是適合在拖鏈中使用的易於連接的電纜。作為製造商和訂製廠商,igus® 從單一來源提供所有產品,從而減少生產時間和供應商的數量。產品組合包含廣泛的目錄產品系列,如根據製造商標準和不同工業標準訂製的電纜以及單獨或量產的部件。許多不同質量、不同類型、符合不同標準、不同認證的電纜可供選擇。所有部件都接受廣泛的品質檢查和功能測試。<br />

<br />

●組裝到好的 readychain®全裝配拖鏈<br />

客製的拖鏈系統:精簡從設計到組裝的流程<br />

我們即插即用的客製拖鏈可將採購選項、零件清單項目、聯絡人數量和安裝工作量降至最少。 這樣以避免不必要的倉儲空間和資源浪費。 它們創造出最佳的解決方案並增加加您的競爭優勢。 它們優化了拖鏈、電纜、接頭、空壓管、液壓管、金屬件、傳感器、PLC、軸承、線性滑軌裝置和其他機械零件的供應鏈。 <br />

拖鏈、電纜、模組化——以 igus® 的全裝配拖鏈優化流程!<br />

<br />

更多資訊: https://www.igus.com.tw/

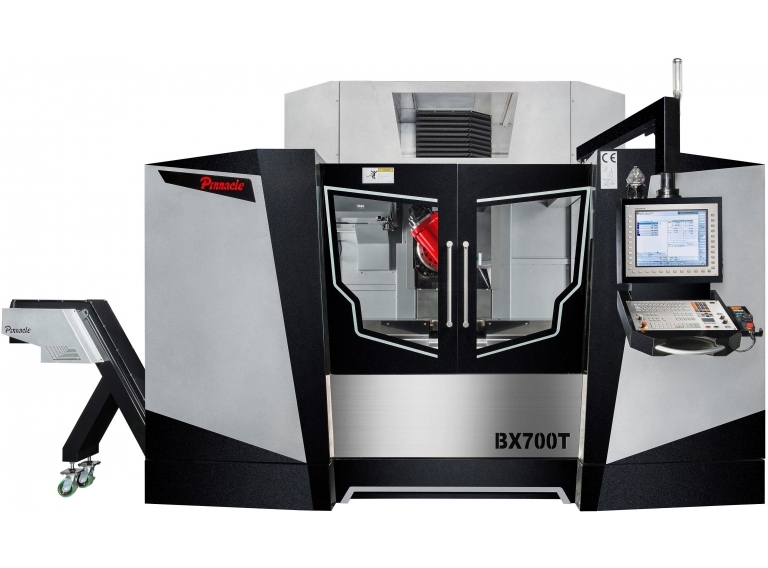

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

製品の説明 :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Cutting Tools

* Applications|Die and Mold

* Customized tool design, lower cutting resistance and torque and better lifetime compared to conventional tools. Reduces the times of tool changes; Suitable for production-related molds.

* Processing Material | NAK80, SKD61, STAVAX, DC53, ELMAX, PD613, HSS, DRM, YXR3, SKHHAP

Graphite, aluminum alloy ADC12, carbon fiber reinforced plastic CFRP, glass fiber GFRP, chemical nickel, copper, oxygen-free copper, various plastic materials PU, etc.

DA CEI TRADE CO.,LTD.

製品の説明 :

* Electric heater for generating the high temp. hot-air of the hige pressure.

* Temp. control can be be satisfactory because A-sensor (for detecting the hot-air of the outlet) and B-sensor (for

detecting the hot-star and overheat temp. ) is incorporated.

* Life of the heater element becomes long and the high temp. hot-air of 800゚C can be used the long time stably by using

with Multi-controller TRC202.

* Hot-start operation for intermittent operation is possible by using with Multi-controller TRC202.

BUFFALO MACHINERY CO., LTD.

製品の説明 :

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining center while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements, with multiple options available based on workpiece specifications:

8 pallets (workpiece max. size 500 x 305 mm; max. weight 220 kg)

10 pallets (workpiece max. size 400 x 305 mm; max. weight 220 kg)

16 pallets (workpiece max. size 230 X 305 mm; max. weight 98 kg)

20 pallets (workpiece max. size 160 x 250 mm; max. weight 30 kg)

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

JIN YEAR PRECISION CO., LTD.

製品の説明 :

Features:

1. This machine has the "CE safety authentication".

2. Operates is fast and simple.The quality is stable.

3. Point Angle 90°~135°.(Generally is suitable 118°)

4. Chisel edge grinding. Can adjusting by your demand.(Generally is suitable 0.7mm)

5. It's the first to research and development "up to down" swinging grinding way.The finished drill is sharpest, and the most durable.

Our company new researches and develops, swing the drill grinding from up to down, very sharp.

Generally rotate the drill grind left to right, it's blunt.