展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

Administration for Digital Industries, moda

製品の説明 :

Transforming maintenance history into a digital knowledge base to enhance maintenance efficiency and reduce learning costs.

1.Establishing SOP standard maintenance procedures

2.Uploading text, images, and videos freely

3.Easily accessing through website and app

4.Customizing knowledge base languages based on different countries

5.Calculating average failure rates by region and machine model

6.Maintenance progress scheduling calendar

7.Remote automatic reporting system

ASMITH MANUFACTURING COMPANY

製品の説明 :

Spring Loaded Draw Latch |The proposed load of 22~50 kgf.

Both sides spring design with compression function.

Standard Lock-hole can using with lock. Suitable for vibration equipment.

Smooth surface, excellent brushed finish appearance, in accordance with RoHS.

The draw latch is including the horizontal keeper [CS(T)-0120-2 or CS(T)0130-2], if you need another type keeper then you can reference the below "Accessories".

➤Material: SUS304(Stainless steel)-vibration ground and brushed finish, SPCC(cold-rolled steel)-zinc plated

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

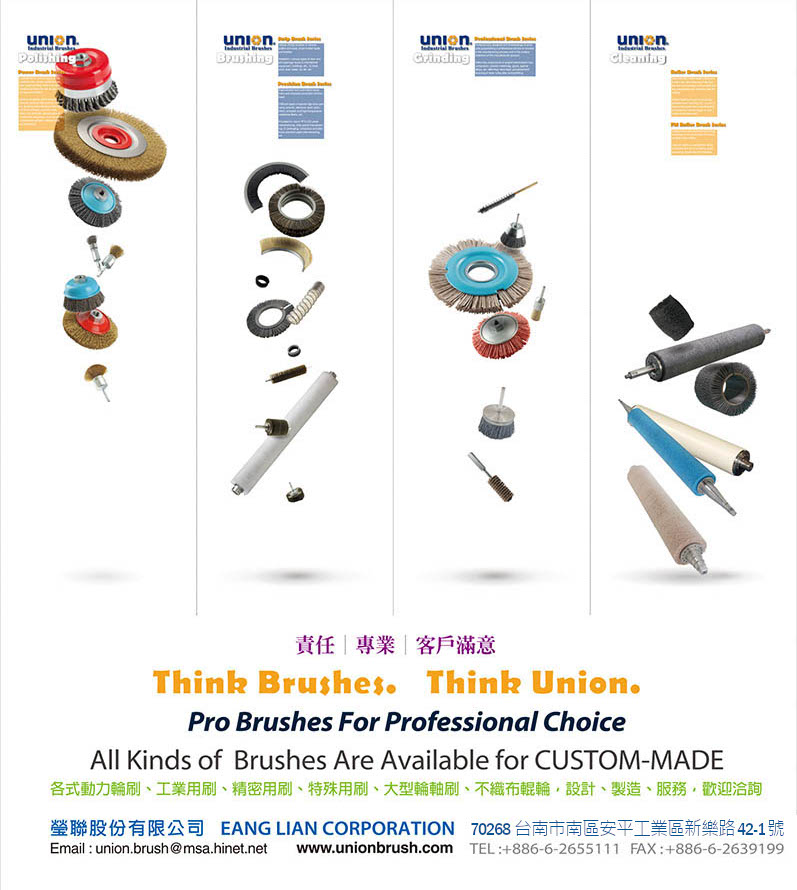

EANG LIAN CORPORATION

製品の説明 :

刷、磨、拋、洗<br />

專業化的設計能力<br />

多樣化的線材應用<br />

客制化的生產系統<br />

提供客戶製程製品-刷、磨、拋、洗.全方位的解決方案<br />

瑩聯股份有限公司—主要供應各式工業用刷是工業用刷之專業設計製造廠、擁有自有品牌(優利牌),產品適用於各行各業。無論需要刷洗、精細研磨、拋光、輕研磨、重研磨、毛邊去除、深孔加工皆有顯著效果!<br />

<br />

主要產品:<br />

1.動力輪刷系列適用於各型電動及汽動工具.<br />

2.矽砂尼龍研磨刷系列可針對各種表面精細研磨.<br />

3.輪軸刷及板槽刷系列接受各種線材及特殊尺寸訂製<br />

4.鋼鐵業退火酸洗、脫脂清洗、刷磨、清洗等大型刷輥<br />

5.德國技術合作專業生產高科技合成纖維輥適-用於鋼鐵軋片產線之刮油輥、塗油輥、擠水輥、張力輥、轉向輥、擠油輥、擠乾輥、擠壓輥、擠水輥、不織布擠水 輥。 6.各種線材及特殊尺寸可依照客戶需要量身訂製

JEFFER MACHINERY CO., LTD.

製品の説明 :

JF-40S is a universal grinder with accuracy grinding technology. It can grind variety of woodworking knife tools, such as woodworking grooving cutter, shank router bit, finger jointer cutter and so on.

On the other hand, 40S is the most important metalworking machining machine tool which can grind knife tools used by Lathe and milling machine, if you need grind variety of machining metalworking knife tools, 40S is the best choice. JF-40S is a precise grinder with multifunction capability and also owns attractive pricing. Besides, JF-40S owns unique function that it is indispensable for broaching machine knife tools.

In addition to JF-40S, we do have JF-60S, JF-150S that is adjusted available on request.

Fey Che Trading Co., LTD.

製品の説明 :

MUGEN COATING PREMIUM Plus具有高抗氧化性和耐磨性,適用於 60HCR 以上的加工。即使在 45~60HRC的加工中也能表現出與 MUGEN COATING PREMIUM 相同的性能。____________________________________________________________

[ 方 頭 銑 刀 ]

[ 型號 : MHDSH445・MHDSH645 ]

*刃長有2D與3D型式可供選擇

*採用最新開發之白金級PLUS無限鍍膜,最適合加工45~70HRC之高硬度鋼材

*高剛性設計實現高精度加工____________________________________________________________

[ 球 頭 立 銑 刀 ]

[ 型號 : MSBSH330-5X ]

*採用耐崩損性佳的新素材及銳角刃口設計,可以減輕切削抵抗

*採用不等分割設計,可以防止震刀

*5軸機專用圓球立銑刀

[ 型號 : MRBSH330 ]

*最優化中心刃形狀、 能進行高切削深的高效率

*加工即使在45〜70HRC高硬度鋼,兼具切削性與

*耐磨耗性,能實現長壽命、高效率的加工

[ 型號 : MRBSH230SF ]

*加工70HRC的高硬度鋼材,也能實現長壽命及穩定的加工性能

*採用耐崩損的新素材及減低切削抵抗的刃口設計____________________________________________________________

[ 端 角 R 立 銑 刀 ]

[ 型號 : MHRSH430RSF ]

*全新的修光刃設計可提升平面加工表面品質

*R角無段差設計,提升側面加工表面品質

*高剛性設計實現高精度加工

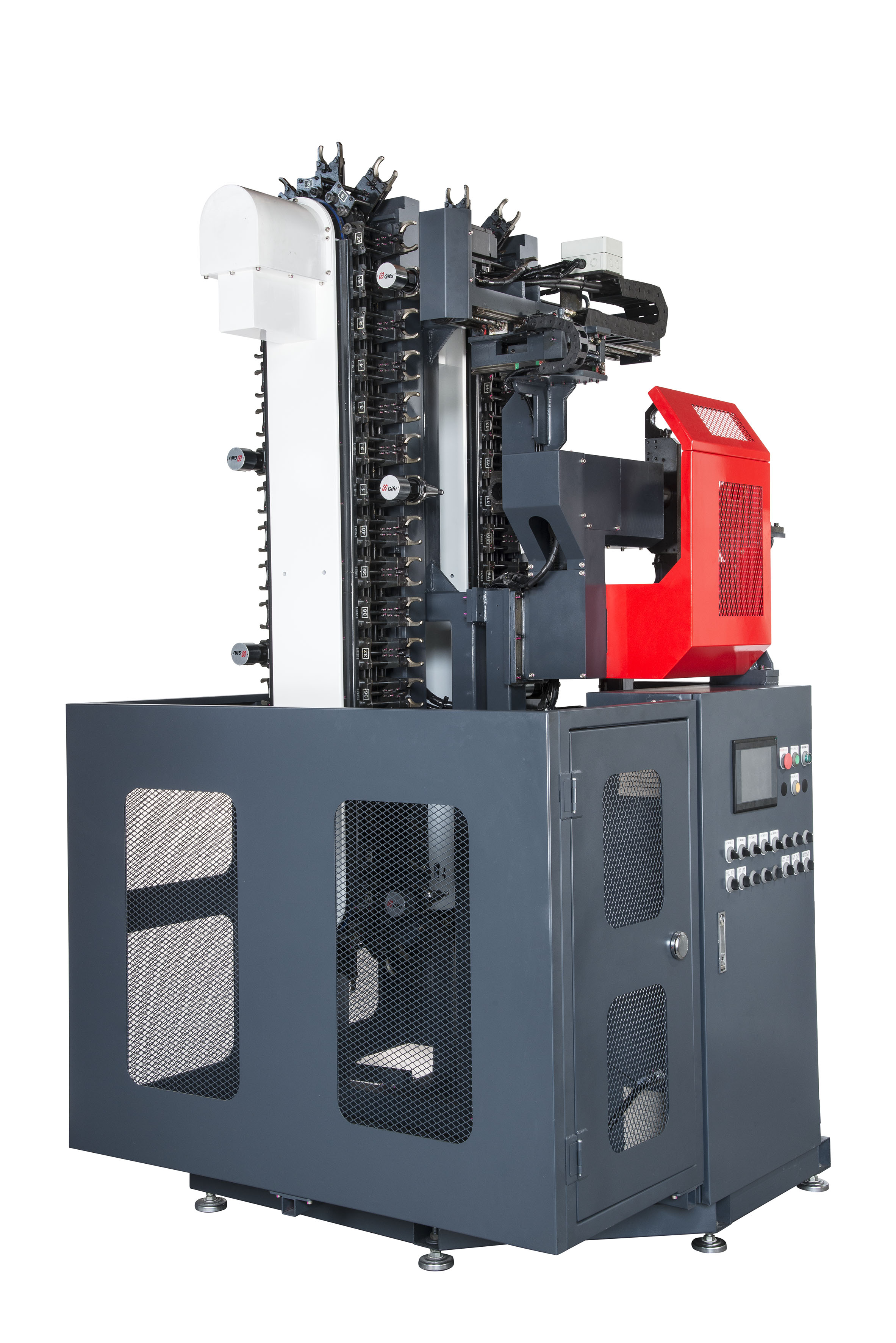

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.The magazine can load 60/120/180 tools by front and rear allocation. Also, the magazine is adopted with high-quality and high positioning accuracy reducer and servo motor driven system.

2.The gripper replaces the tool pot to catch tools and achieve the purpose of lightweight and modularization

3.Innovative sub-tool pot tool catching system reduces 30% of the volume. The design of lightweight structure with fast moving speed achieves max. speed at 15m/min and the positioning accuracy of heavy loading is within ±0.1mm.

4.Two-stage advanced speedy tool changing system The best tool changing time can be adjusted according to different tool weights. The tool under 3 kg can complete tool changing procedure within 1 second.

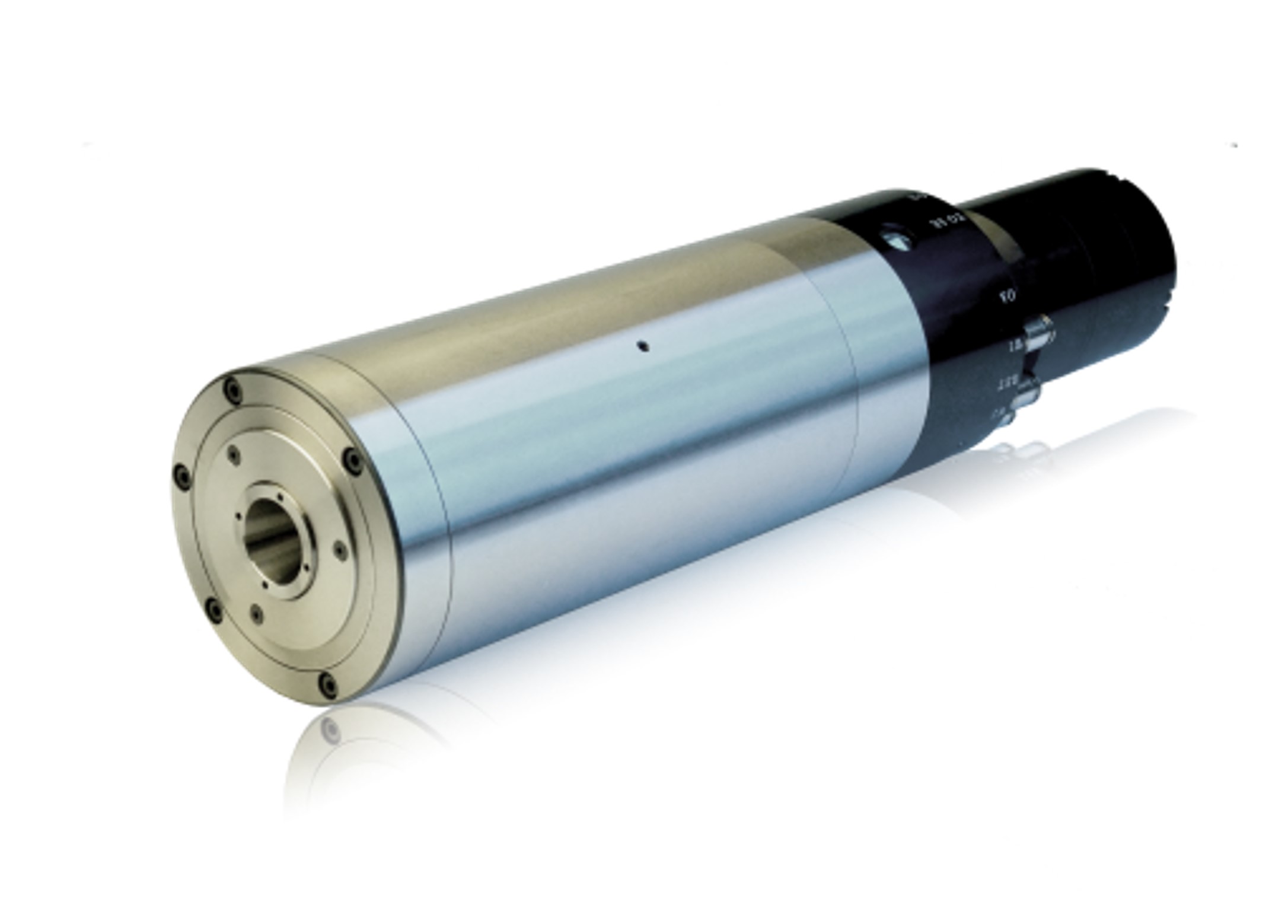

GRINTIMATE PRECISION INDUSTRY CO., LTD.

製品の説明 :

a.Equipped with the exclusive hydrostatic spindle.

b.Equipped with the exclusive hydrostatic guideway .

c.The grinding wheel can be widened to 300mm with one-feeding grinding.

d.Headstock and tailstock both work with double sided synchronous.

e.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process