展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HOLDING ELECTRIC CO., LTD.

製品の説明 :

The magnetic grinding machine is an innovative product of Holding Electric, and has won invention patents from many countries in the world

This patented device generates a magnetic field that motivates magnetized pins to bounce rapidly and to grind parts

Features

1.For High Precision

2.Grind Every Corner:

Effect

1.Deburring

2.Polishing

WEXTEN PRECISE INDUSTRIES CO., LTD.

製品の説明 :

■ Maintained the constant oil temperature in order to prevent process-ing precision-losing.

■ Kept oil viscosity and avoid oil deterioration to stable spindle working.

■ With the temperature control panel to avoid thermal expansion.

■ Built-in failure-detection system that connects to control panel in order to warn users and prevent further damage to machine.

■ Filling high-efficiency environmental refrigerant, without pollution.

SHE HONG INDUSTRIAL CO., LTD.

製品の説明 :

Huge Range of Machining Heads Hartford delivers a full range of machining head options to customize the machine to your particular cutting requirements. We also offer the auto swivel arm head changer to automate the head changing process and save you machining time.

Automatic heads

+Automatic Universal Head(5°/2.5°/1°)

+Automatic 90° Head(5°/2.5°/1°)

+Automatic Extension Head(350/500mm)

EQP SERIES CO., LTD

製品の説明 :

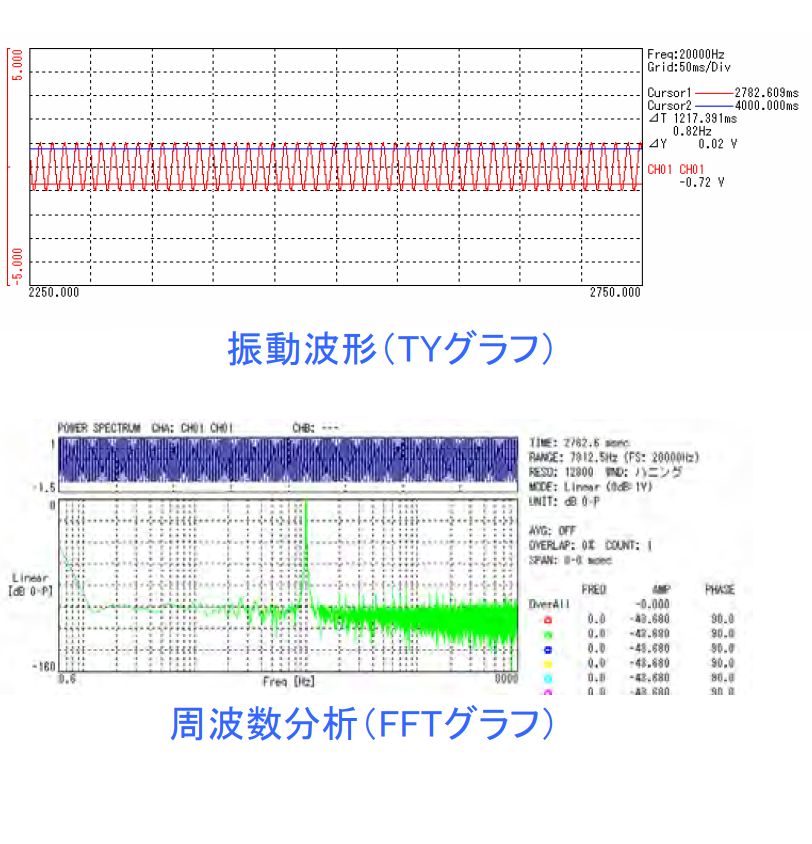

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

HERBERT ENTERPRISE CO., LTD.

製品の説明 :

1.Modelling

The main structure could do universal machining with soft or hard jaws without any limit of angle.

2.Function

The universal vise is suitable for milling, lathe, and CNC machining center especially for 5-axis CNC machining center with 200-1000cm machining table and 12000 rpm. The swivel base can move in two-way to find the center point, easy and efficient to meet customer’s requi-rement.Can be mounted to CNC machining center to rotate the work-piece via swivel base for processing.

3.Quality

With the heat treatment alloy steel, it’s hardness reach 50-60 degree with high durable quality. The parallelism accuracy reaches to 0.01mm. The main body can support the sliding base increase its stability.

4.Innovative

HERBERT TMV successfully conveys the spirit of HERBERT - reliable, stable, innovative and professional.

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

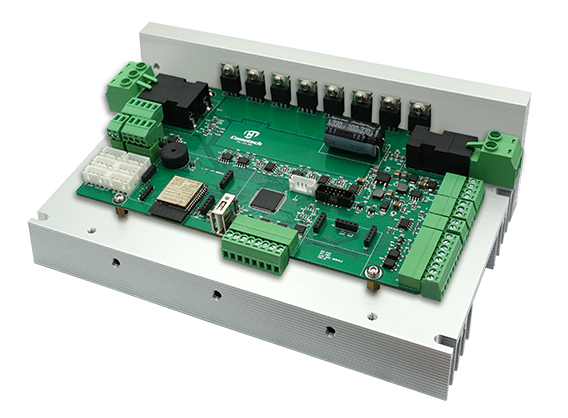

Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 800W

-Rated Current: 35A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Speed Control: Analog input, Digit input, PWM, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

HOLD WELL INDUSTRIAL CO., LTD.

製品の説明 :

● With a U-Drive unit commanding the feed control of the tool slide and the tool placement even during rotation, it is made to o er the solution to a series of processes such as threading, conical threading, grooves, slots, curve surface machining and other complex pro

les. It makes it possible to

do turning operations on all machining centers.

● It is designed to be used on automatic tool changers to maximize the working e

ciency.

● Modular tool-holder slide with interchangeable design permits the various tool applications and machining.

● It is specially designed with two counter-weights for automatic balancing, which move opposite to the slide to e ectively eliminate oscillations.

Taiwan Auto-Design Co.

製品の説明 :

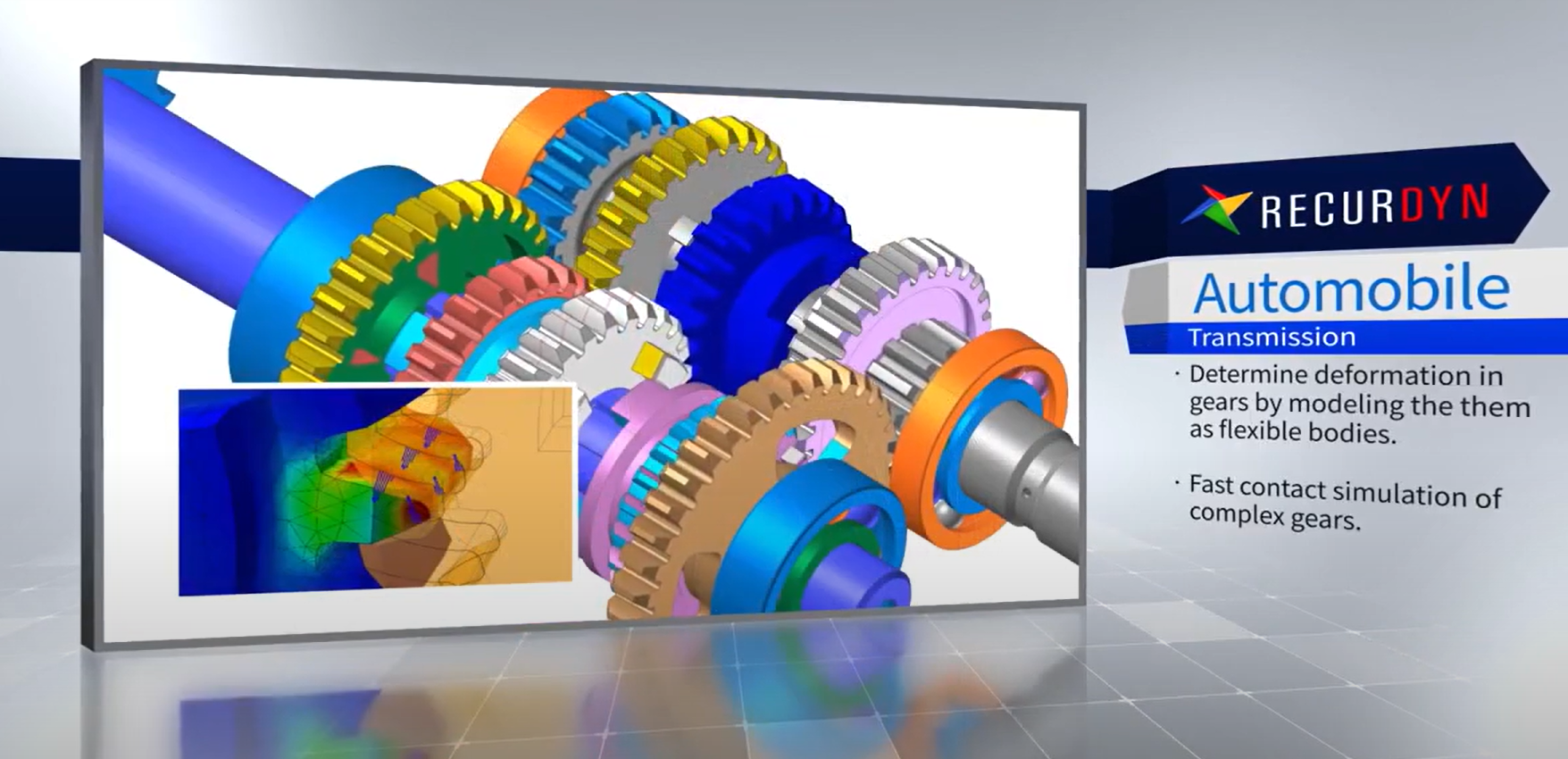

RecurDyn is an interdisciplinary CAE (Computer-Aided Engineering) software based on Multi-Body Dynamics (MBD).

It provides fast and efficient solvers, an intuitive interface, and various libraries.

RecurDyn simulates both rigid and flexible body dynamics by combining traditional rigid MBD with cutting-edge

finite element technology for modeling flexible bodies. In addition to MFBD (Multi Flexible Body Dynamics), RecurDyn

also includes a tightly integrated controller design tool, design optimization, and durability and fatigue analysis.

RecurDyn also supports co-simulation with various other CAE software tools. It enables a seamless co-simulation

environment (Particleworks Interface) for coupled simulations with computational fluid dynamics solver, Particleworks,

allowing for detailed analysis of the interaction of fluids and multi-body systems.

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Linear encoders are indispensable for machines with high demands regarding positioning accuracy and machining speed. Linear encoders directly and immediately measure the actual position of the feed axis. This makes it possible to eliminate a number of potential error sources: Positioning error due to thermal behavior of the recirculating ball screw

, Reversal error, errors due to deformation of the drive mechanics by machining forces, kinematic errors through pitch error in the recirculating ball screw.

BENIGN ENTERPRISE CO., LTD.

製品の説明 :

• Selective bed width: 300 mm

• With FAG or SKF precision bearings installed on spindle, maximum cutting depth can be 8 mm on 50 mm diameter and best roundness 0.003 mm (200 mm long).

• Thermal treated and precision ground alloy gears.

• Universal gearbox for both imperial and metric thread-conversion table also attached.

• Tracks of cross slide and bed are well lubricated with lubrication pump (manual).

• CE certified