展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

AUTOBLOK COMPANY LIMITED

製品の説明 :

1 .用戶可降低安裝時間高達90%

2. 最高的工藝可靠性和重複精度<0.005 mm

3. 完全密封

4. 由於渦輪增壓功能,最大牽引力可達45 kN(APS 190)

5. 由於經過熱處理的元件和額外的硬質保護塗層,因此具有耐磨性和防銹(或不銹)性

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

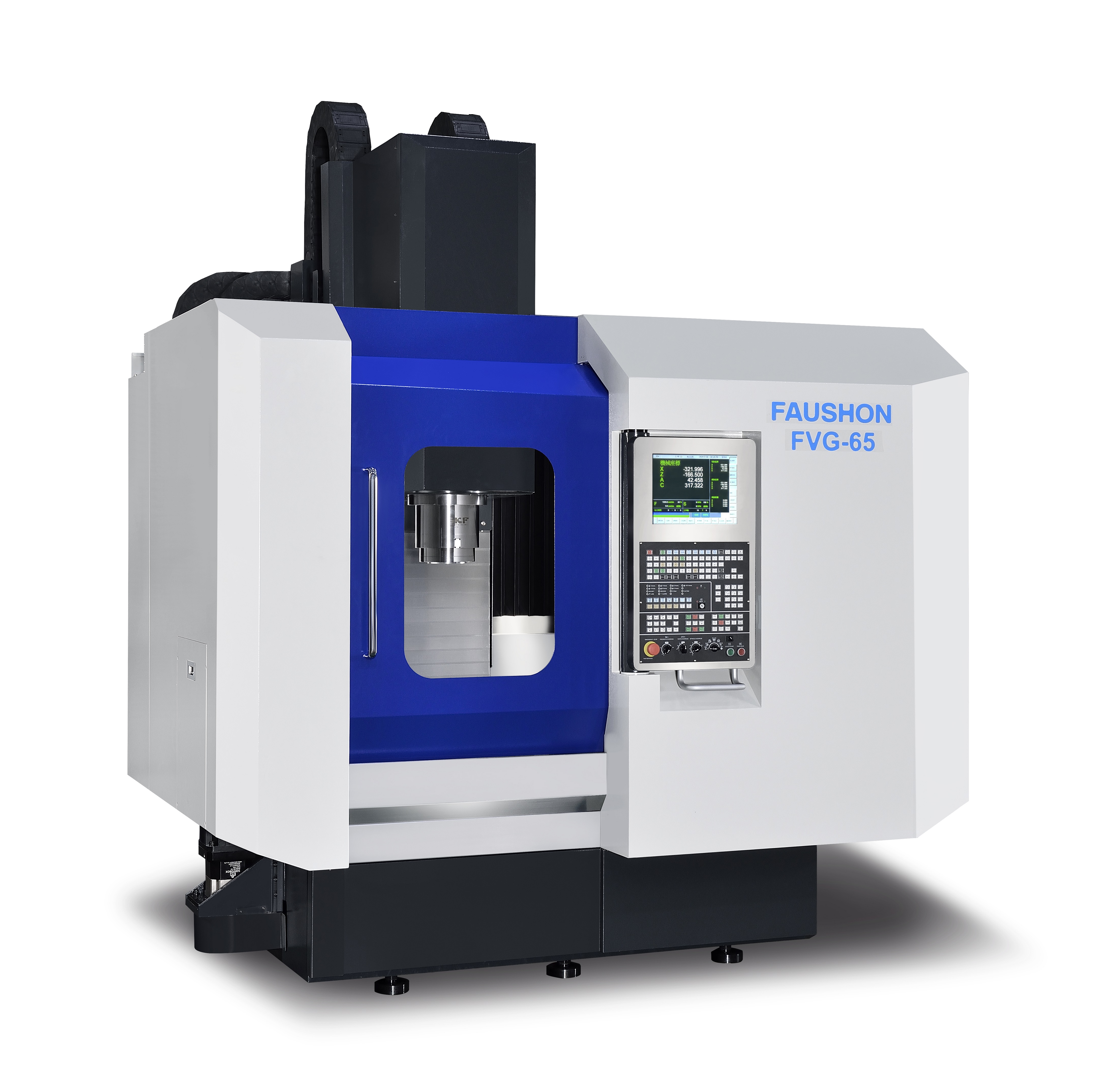

Fulson Industrial Co., Ltd

製品の説明 :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.

HSU PEN INTERNATIONAL PRECISION MACHINERY CO., LTD.

製品の説明 :

*Employs high rigidity, extra large radial and axial bearing.

*Equipped with special labyrinth type multi-piece disk brake that provide multi-surface braking. Big area design effectively increases clamping force. The table structure eliminates table surface floating problem.

*Big hole design makes machining more convenient. Manufactured from high quality, durable cast iron. Increased body thickness increases load resistance capability. Large through-hole diameter. High strength, heavy cutting resistance as well as high precision.

HC FENG CO., LTD.

製品の説明 :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

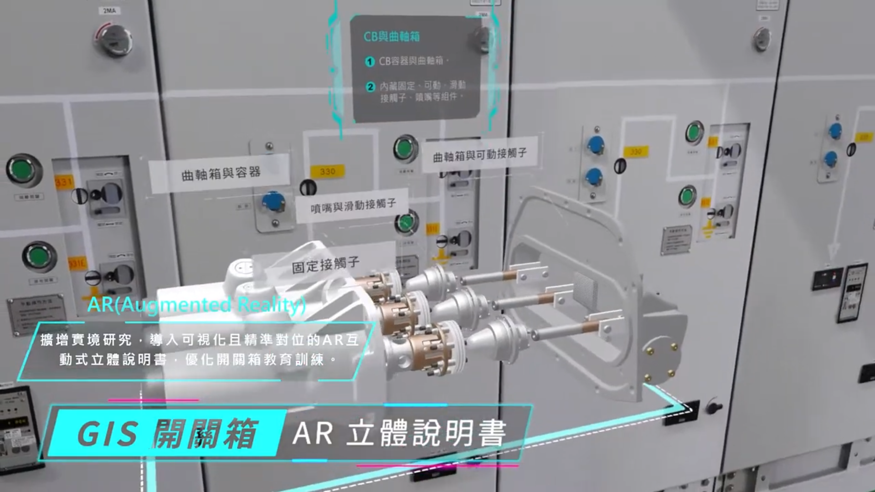

Administration for Digital Industries, moda

製品の説明 :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

LINTRONIX CO., LTD.

製品の説明 :

瑞士ABB PMA針對工具機的應用,提供相對應的解決方案:例如針對加工區配管需要抗鐵屑噴濺、高IP防護等級,研發出三層電線保護管與IP69耐高壓水柱沖擊的產品;針對需要較高抗壓強度的機台外部配管,俱彈性又耐高壓荷力不變形的保護管;針對加工區上下料自動化設備配管,可提供耐撓曲的產品。PMA產品俱有難燃性、低煙、無毒等特性,符合歐盟CE規範與UL認證,滿足工具機廠外銷歐美市場的需求。