展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

MAROX TOOLS INDUSTRIAL CO., LTD.

製品の説明 :

External Turning Tools、Boring Bar、Tool holders for Threading、Boring Bars for Threading.

Fulson Industrial Co., Ltd

製品の説明 :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

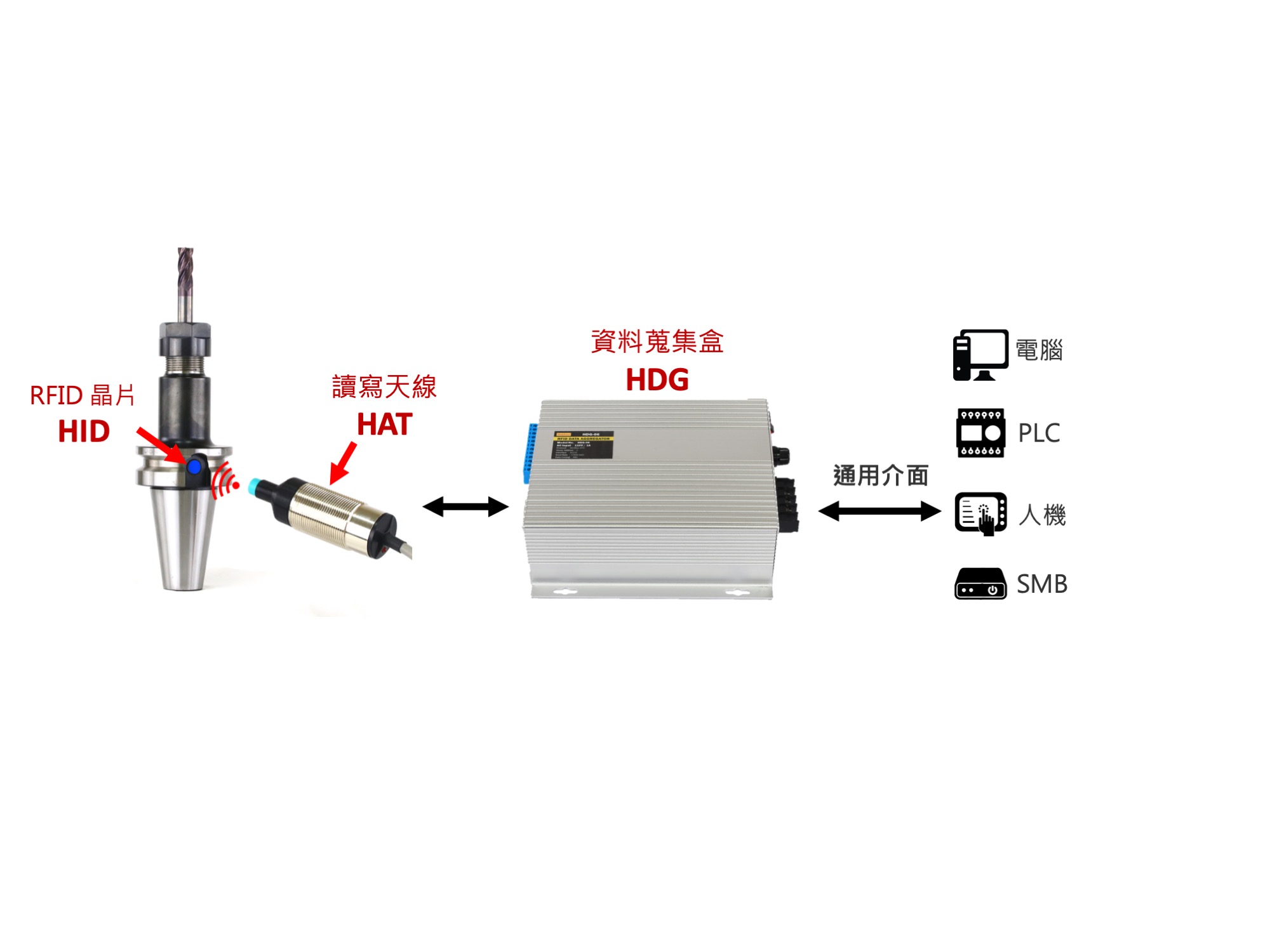

HOLDING ELECTRIC CO., LTD.

製品の説明 :

豪昱自主研發,國產工業級RFID系統。適用於智慧刀具或模具管理等工業物聯網loT應用。本系統為台灣生產製造,價格俱競爭力並提供完整富彈性的技術支援

DI CHUN IRON WORK CO., LTD.

製品の説明 :

1. CRANK structure N-type extra long stroke.

2. High-strength alloy, all sliding surfaces are hardening and grinding.

3. Can clamp over workpieces will extremely uneven surface.

4. The installation is the same as the N-type chuck replaceable change.

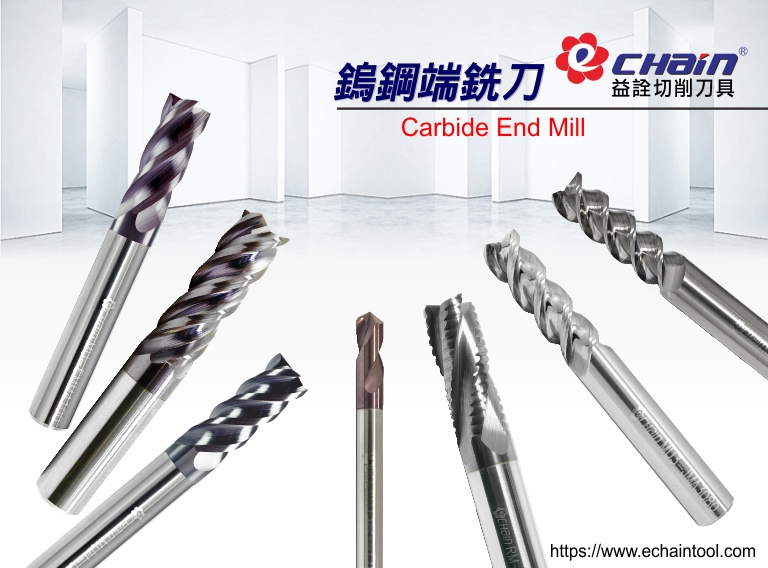

ECHAINTOOL PRECISION CO., LTD.

製品の説明 :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

SHEN SHAN INTERNATIONAL GLIDE MFG. CORP.

製品の説明 :

Twin caster with brake , can be assembled plate, stem with ring, stem, screw

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

JAINNHER MACHINE CO., LTD.

製品の説明 :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

ZHONG YANG CUTTING TOOLS CO ., LTD.

製品の説明 :

阻尼吸震刀桿為本公司專利產品,

抗震倍數可達到12倍!

影片連結:

https://www.youtube.com/watch?v=cnFy1i0elvI&t=6s