展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

KAO FONG MACHINERY CO., LTD.

製品の説明 :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The MT-900 has a 5-axis milling head, two turrets, a tool magazine and twin spindles.

The design layout allows for maintaining a large work envelope for both lathe operations-turning and milling.

All six sides of a part can be machined without an operator having to manually resettle the workpiece, so nearly any parts can be machined in an automated manner.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

TMT TG series with meticulous design, is your best choice in precision finishing. Multi-performance, while satisfy different machining demand. Work table can be mounted with APC, 5 Axes or fix table.

-High cutting rigidity with ganty type structure design.

-Compact design less floor occupation.

-Without carring ATC system on moving parts to make it lighter, make sure cutting without vibration.

- Cutting area isolation to ensure the transmission system life longer and easier to install linear scale.

-High efficiency servo drive ATC system, C-C(T1-T2)only 4sec., with high stable performance.

-ATC install at the center of basement to reduce the width of machine to save the walking steps to loading and unloading workpiece.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

CAMPRO develops a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. The T Series are focus on cutters which is able to adjust the width according to different cutter such as milling, drilling, end-mill, tapping and so on. The patented transmission system allows user to select and dispense, withdraw cutters easily. Available to augment cabinets, max. support 100 cabinets. (Disc Type Cabinet, Tools Holders Cabinet, Recycling Cabinet, Compartment Type Cabinet, and Drawer Type Cabinet)

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

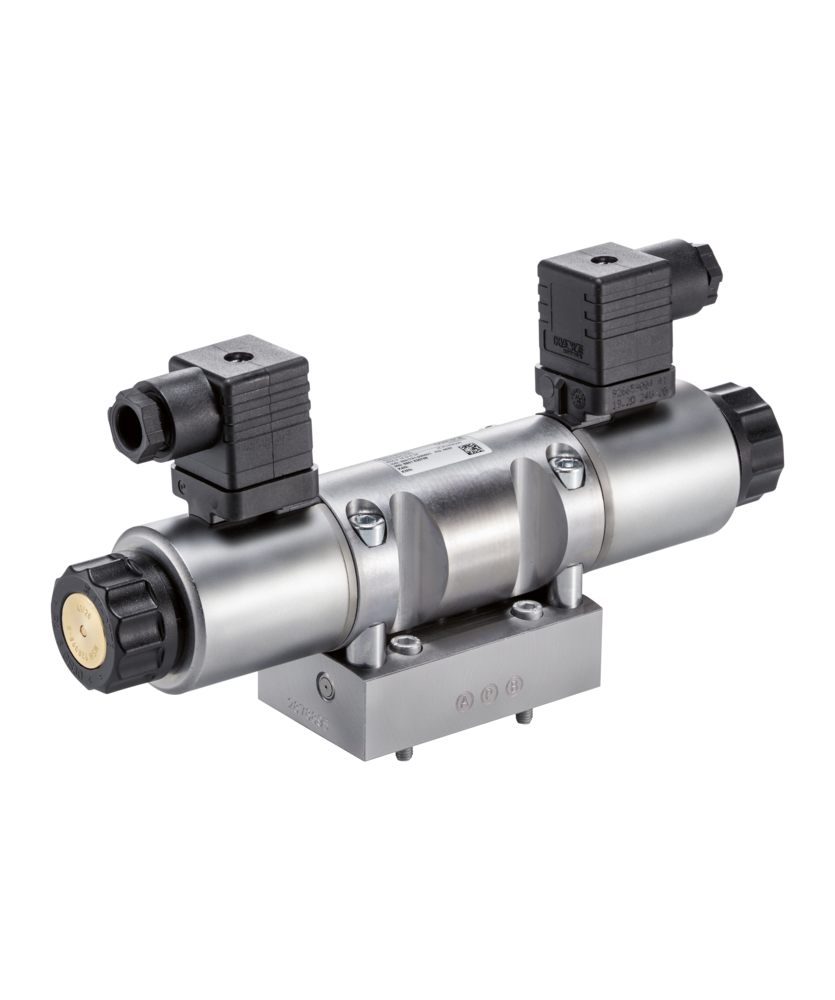

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

MANFORD MACHINERY CO., LTD.

製品の説明 :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

EUMACH CO., LTD.

製品の説明 :

HSM-5X系列是最新的機器與萬能的應用,完美回應數控五軸加工與工件的定位與刀具軸空間要求,為複雜零件的加工提供了廣闊的應用範圍。

本機採用C型架構,機床為高剛性完全支撐結構,機械經久使用,能長時間維持穩定狀態,旋轉銑頭B軸與旋轉工作臺C軸為獨立分開無重迭之兩旋轉軸,便利於工件、刀具及夾制具等設計及擺放,尤其相互干涉現象較旋轉兩軸重迭之銑頭或工作臺大幅減少。並可選用車銑主軸及高速旋轉工作台,達到車銑複合綜合加工。

HSM-5XC是大型高效切割和加工應用的最佳解決方案,無論您的重點是靈活的單元生產還是大批量精密製造,如航空工業的渦輪葉輪,葉盤等,或醫療的心臟瓣膜,人工關節或牙齒等,當然,一般加工,如模具加工或僅5面或多面加工都非常容易!

本機採用實的米漢娜鑄鐵結構,三軸為重型滾柱直線導軌進給系統,能很短時間內加速到48m/min,三軸行程1020/610/610mm,力矩電機驅動B軸連續擺動銑頭0.001角度分割,旋轉範圍-30~120゚,裝進口電機主軸26&32Kw / 124&154Nm / 18000RPM/HSK-A63設計及標準長工作台崁入φ610mm由力矩電機驅動的旋轉工作臺(C軸),最大轉速50RPM承重500KG,搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,刀臂式60把刀,該加工中心用於多面高性能加工和最智能的加工概念提高了生產力。

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

■ The unique IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

■ Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

■ High precision rotary encoders in the B and C

axes as a standard feature, allowing for the most demanding machining accuracies.

■ ø650 mm table provides stable machining performance with a wide machining area and trunnion support.