展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

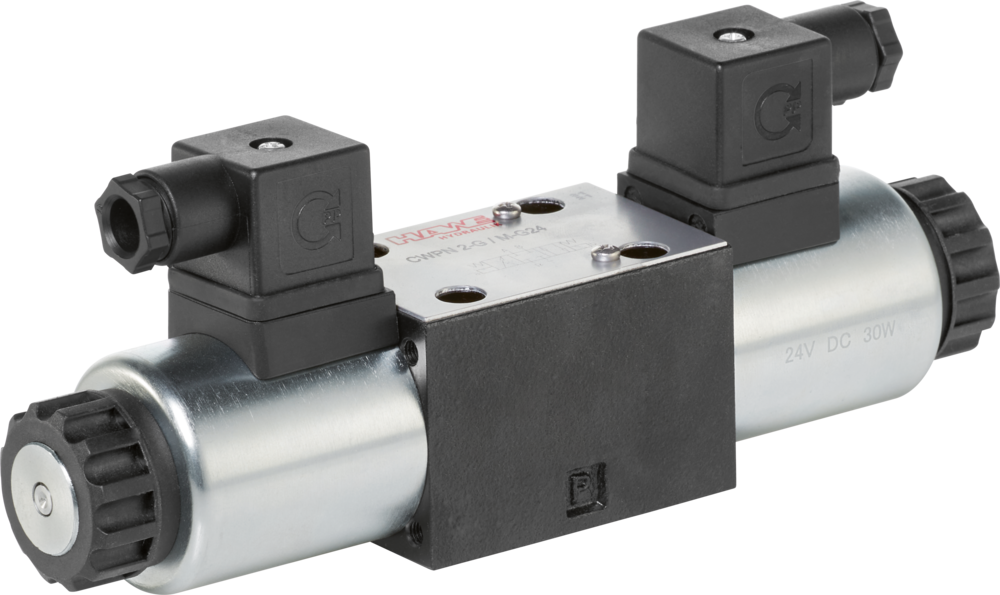

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

製品の説明 :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

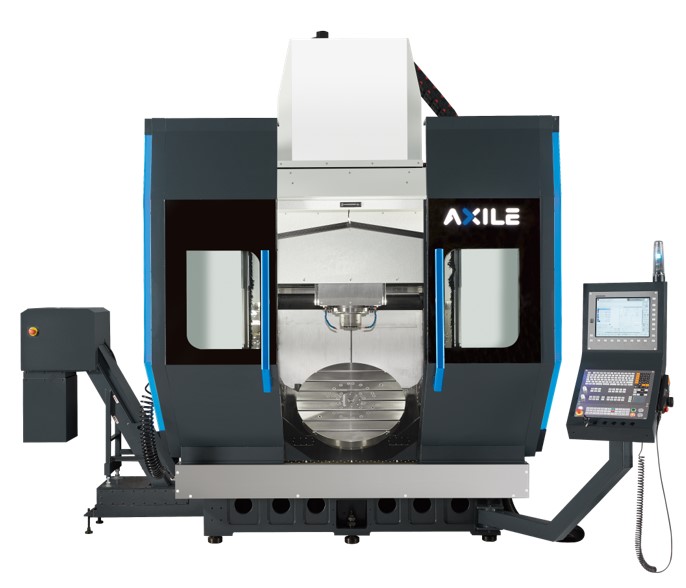

BUFFALO MACHINERY CO., LTD.

製品の説明 :

The AXILE G8’s powerful gantry design perfectly balances rigidity and precision, ideal for the machining of complex workpieces.

With a maximum loading capacity up to 1,300 kg on a swiveling, rotary table, complemented by high-performance built-in spindles, the G8's agility enables production of a wide range of large parts and tools.

The G8 MT option offers both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G8 MT can efficiently machine a wider variety of parts, including cylindrical components.

BENIGN ENTERPRISE CO., LTD.

製品の説明 :

• Selective bed width: 300 mm

• With FAG or SKF precision bearings installed on spindle, maximum cutting depth can be 8 mm on 50 mm diameter and best roundness 0.003 mm (200 mm long).

• Thermal treated and precision ground alloy gears.

• Universal gearbox for both imperial and metric thread-conversion table also attached.

• Tracks of cross slide and bed are well lubricated with lubrication pump (manual).

• CE certified

CENTURY TRADING CORPORATION

製品の説明 :

高性能

● 高速、高精度、高功率

● 穩定加工

● 廣泛的應用範圍

高效率

● 高可靠性

● 充實的預防維修功能

● 便於保養維護

易操作

● 優異的操作性

● 高擴展性

● 自動化對應

SPINDLEX TECHNOLOGIES CO., LTD.

製品の説明 :

Spindle housing diameter : 120mm

Tool interface : Quill D22/38 M22XP2.0

Maximum speed : 42,000 RPM

Lubrication : Oil-Air

Motor power : 11.5/17 Kw

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

主功能介紹:<br />

全中文畫面,易學、易懂、易用,為加工業最適合的加工軟體,操作軟體完全不用背指令。<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

參數式的加工資料設定,作CAM只需三個步驟:(1)選擇工法(2)指定加工參數(3)計算、轉出加工G碼。<br />

參數式的資料設定,圖形改變後,加工碼會自動隨之改變。<br />

智慧型功能:<br />

工法和加工的輪廓可直接複製修改,不必再重新指定。<br />

自動清角可自動清除前一把刀具,所留下來的角落殘料。<br />

鑽孔時依據孔徑大小,自動搜尋鑽孔的加工位置,不必每一孔都去點選指定。<br />

字型可自動截割輪廓外圍不用慢慢編修。<br />

支援單筆劃字型刻字。<br />

加工路徑最佳化,各加工路徑間依最短距離自動計算,且可指定各加工路徑間不提刀以縮短加工時間,達到最佳之加工效率。<br />

立體加工: 不必畫3D曲面圖形就可做出立體加工工法,簡單夾治具可自行製作。<br />

牽引面加工:可加工彎管、簡單的立體。<br />

規則面加工:規則斜面、四角錐面、圓錐面。<br />

旋轉面加工:圓球面、葫蘆形狀。<br />

Z軸投影加工:可在不等高的平面上作投影加工。

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 1850 x 650 mm

Longitudinal travel: 1500 mm

Cross travel: 800 mm

Y slide way width: 1000 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 40~3000 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 5500 kgs

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.