展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JIN LI CHENG CUTTING TOOL CO., LTD.

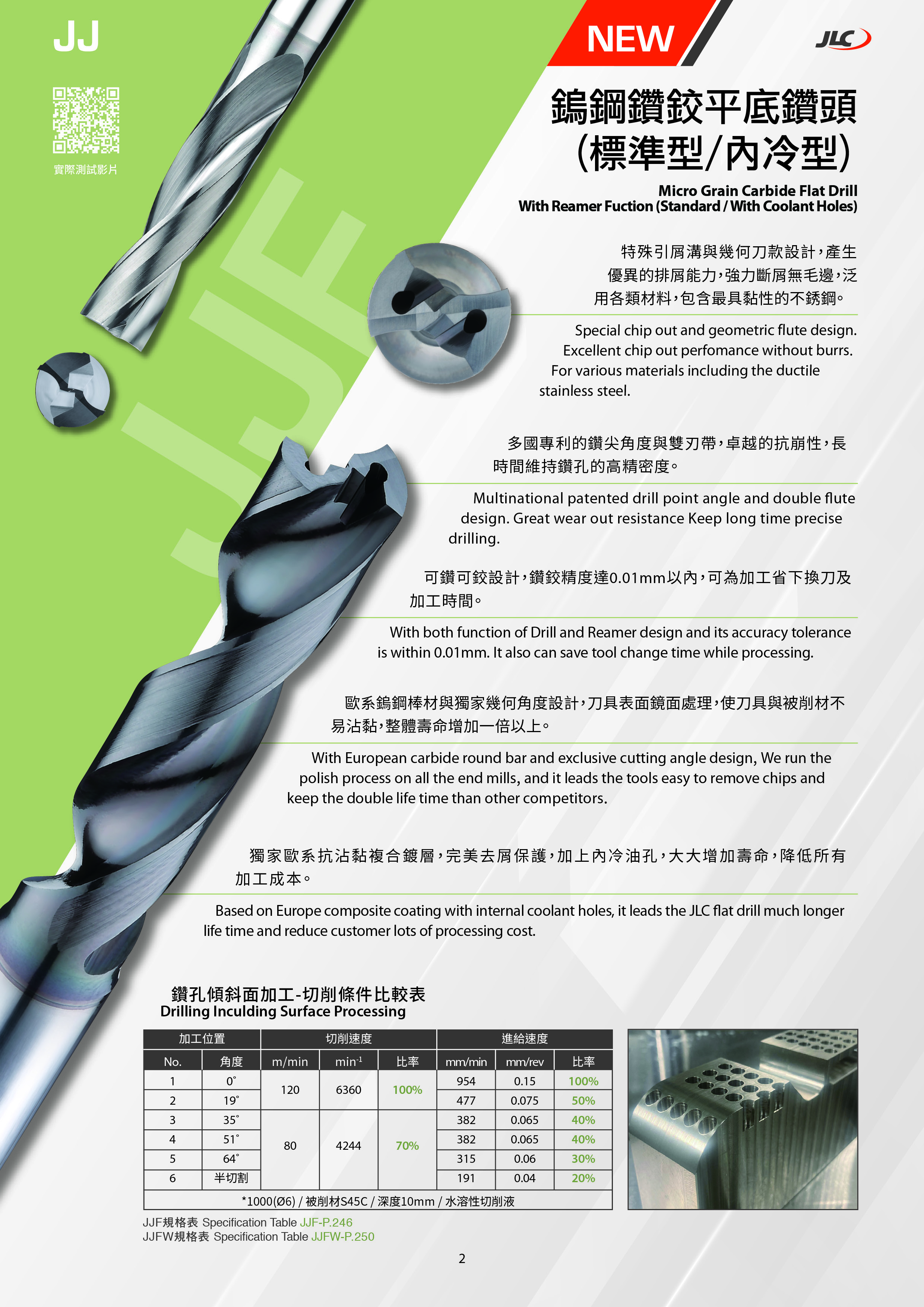

製品の説明 :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

7-LEADERS CORP.

製品の説明 :

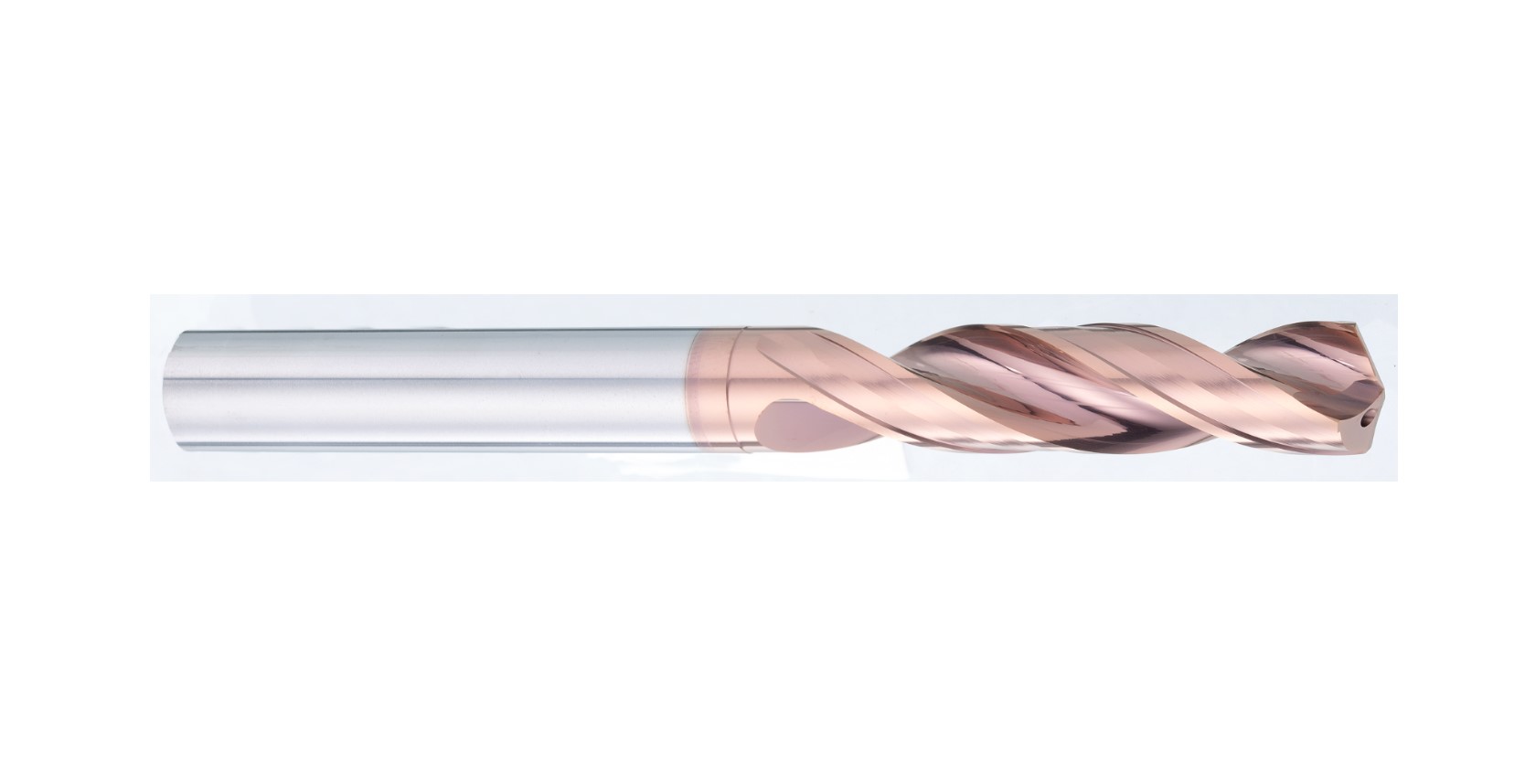

JIS 3XD Drills with Oil-Feed

140° S-shape drill tip design to reduce axial force.

Design with groove shape to provide higher chip removal rates.

Good wear resistance and lubrication with Nano multilayer coating.

Oil-feed design could reduce temperature effectively and increase chip removal rates during cutting process.

Application for drilling with Steels which under HRC48, Cast Iron…etc.

Suitable for drilling with 3XD depth.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

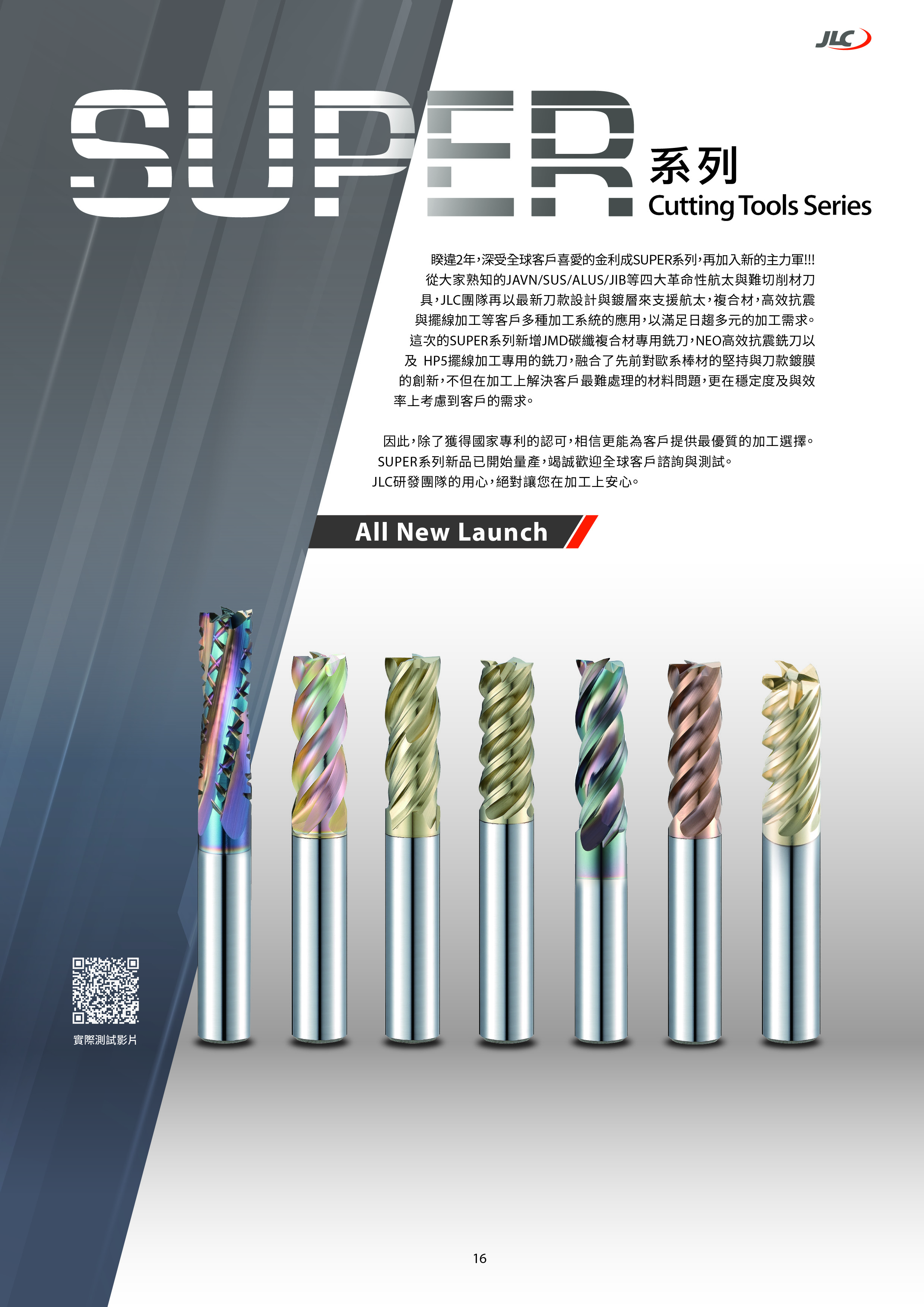

睽違2年,深受全球客戶喜愛的金利成SUPER系列,再加入新的主力軍!!!

從大家熟知的JAVN/SUS/ALUS/JIB等四大革命性航太與難切削材刀具,JLC團隊再以最新刀款設計與鍍層來支援航太,複合材,高效抗震與擺線加工等客戶多種加工系統的應用,以滿足日趨多元的加工需求。

這次的SUPER系列新增JMD碳纖複合材專用銑刀,NEO高效抗震銑刀以及 HP5擺線加工專用的銑刀,融合了先前對歐系棒材的堅持與刀款鍍膜的創新,不但在加工上解決客戶最難處理的材料問題,更在穩定度及與效率上考慮到客戶的需求。因此,除了獲得國家專利的認可,相信更能為客戶提供最優質的加工選擇。

SUPER系列新品已開始量產,竭誠歡迎全球客戶諮詢與測試。

JLC研發團隊的用心,絕對讓您在加工上安心。

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) margin improves stability in deep-hole applications.

The series contain AD-2D/4D (without oil hole), ADO-3D/5D/8D (with oil hole), ADO-10D/15D/20D/30D/40D/50D (deep-hole application with oil hole)

Two point form based on the processing length:Wavy point form with oil hole makes long tool life become possible by breaking chip into small manageable pieces, lowing thrust resistance and stabling torque.

Straight point form with oil hole has both superior point strength and low cutting force.