展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

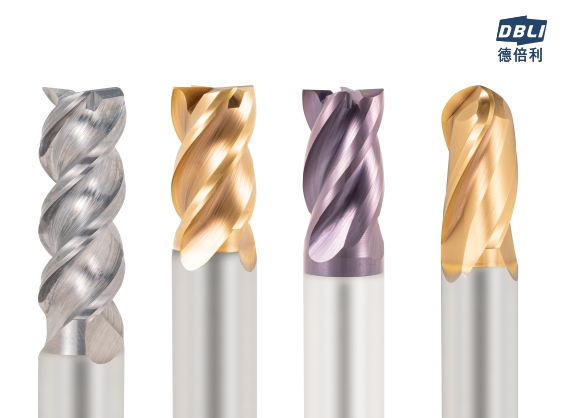

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

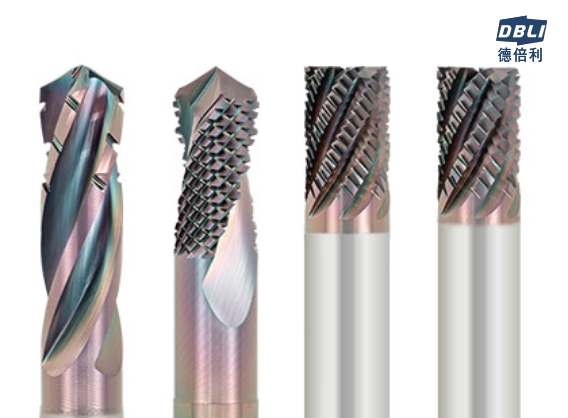

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

7-LEADERS CORP.

製品の説明 :

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.

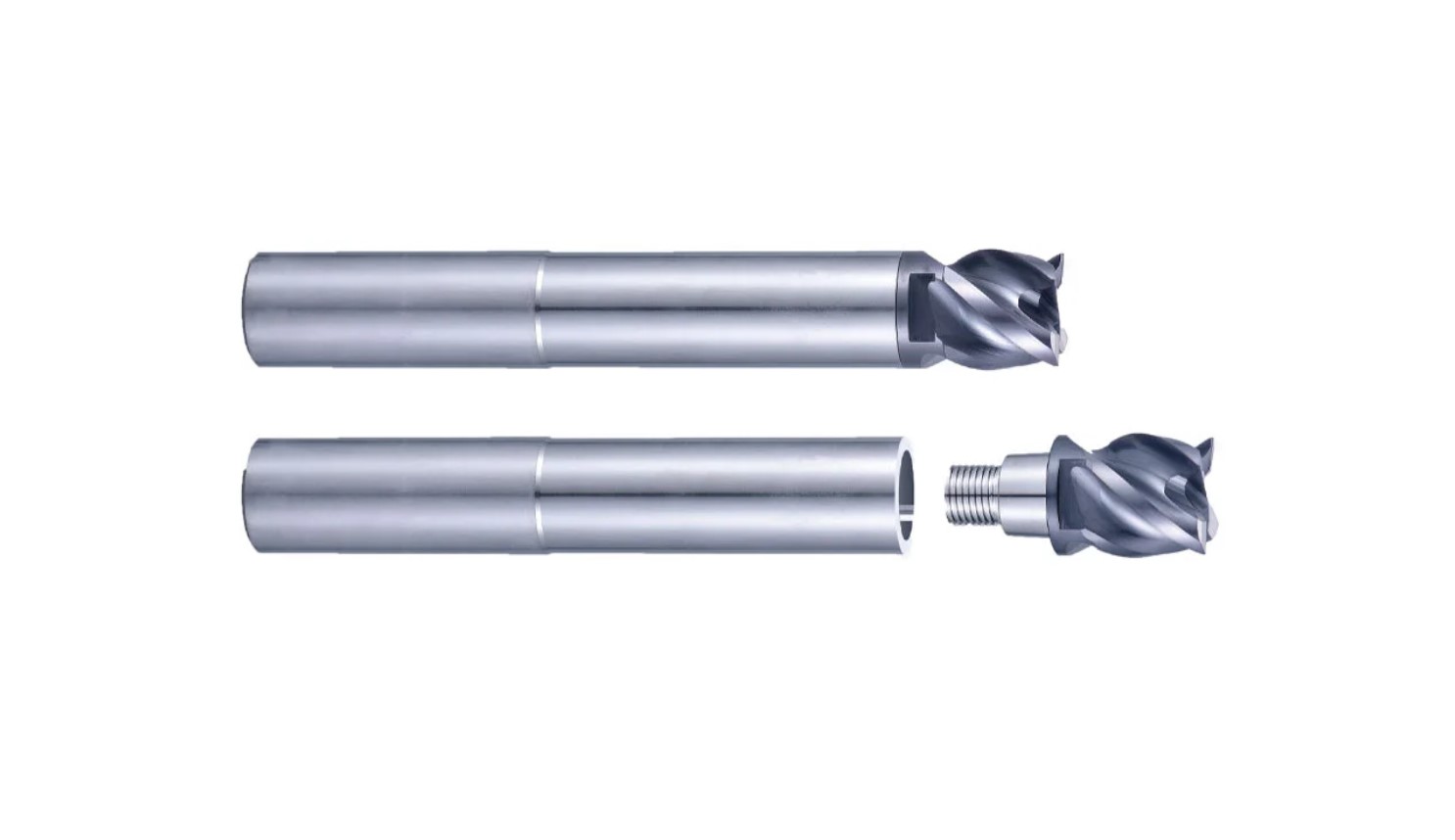

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

AE-VM features good stiffness, unequal lead and helix angle to enhance anti-vibration.

New flute design fulfills better chip removing.

New Coating “DUARISE” provides advantage on lubricity, wearability, high temperature oxidation resistance, and muti-layer structure can prevent it from thermal cracking.

Standard Type and Short Blade Type(AE-VMS、AE-VMSS):Square, Radius, and 90°(-RA) end mill.

3D, 4D Long Blade Type(AE-VML):Square, Radius, and Chip-breaking flute(AE-VML-N) end mill.

Side Milling Type(AE-VMFE): Square, and Radius end mill.

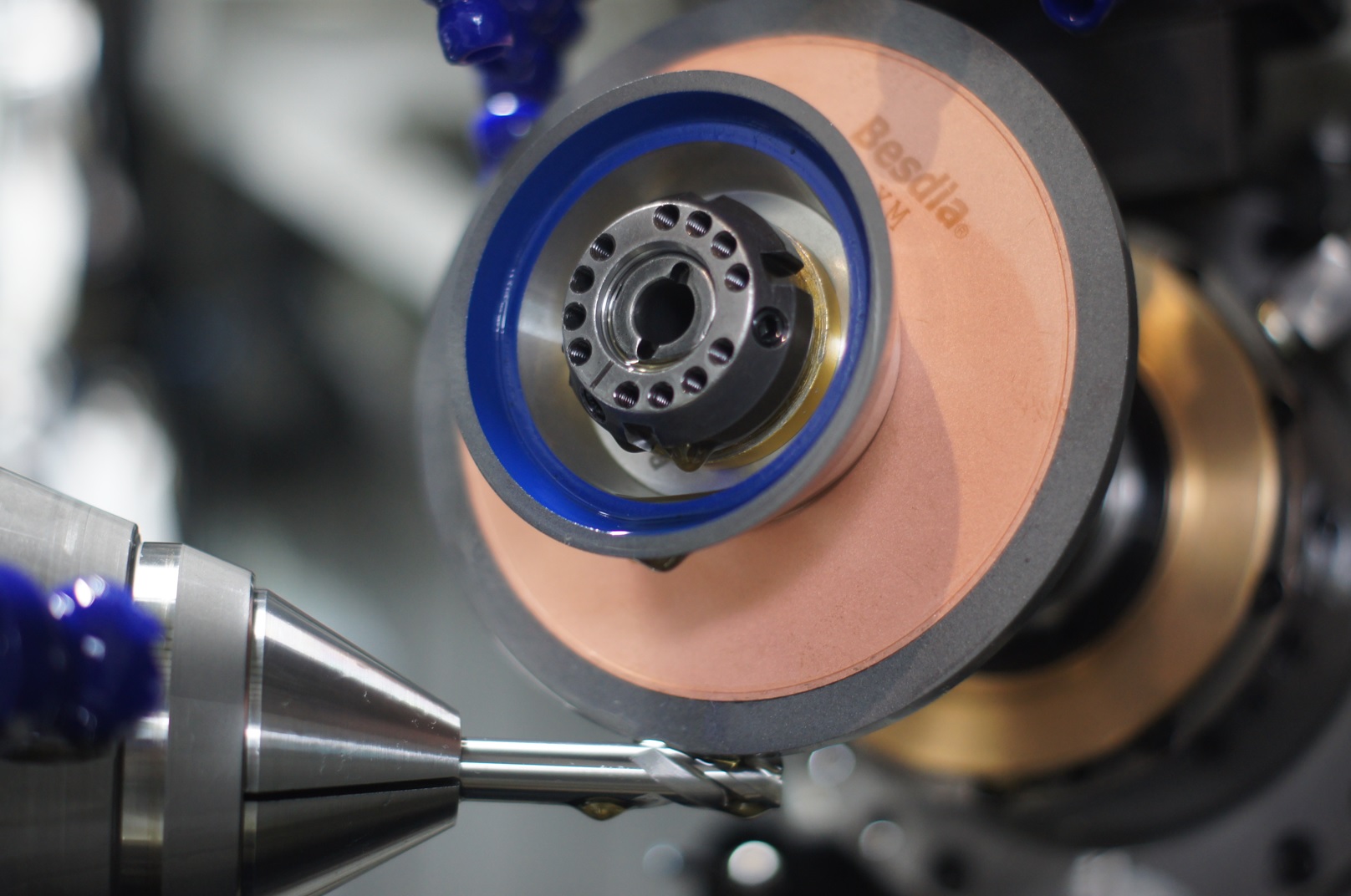

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1.With excellent features of coating to increase the tool life and wear resistance performance.

2.With unique geometry to effectively remove fabric residue.

◆Cutter Speialized in Cutting Fiber End Mills:

Patented flute shape/new design.

◆Cutter Specialezed in Cutting Fiber Drills:

Excellent performance in drilling burrs and tearing.

◆ Cutter Specialized in Cutting Fiber Drill End Mills:

Suitable for thru hole machining.

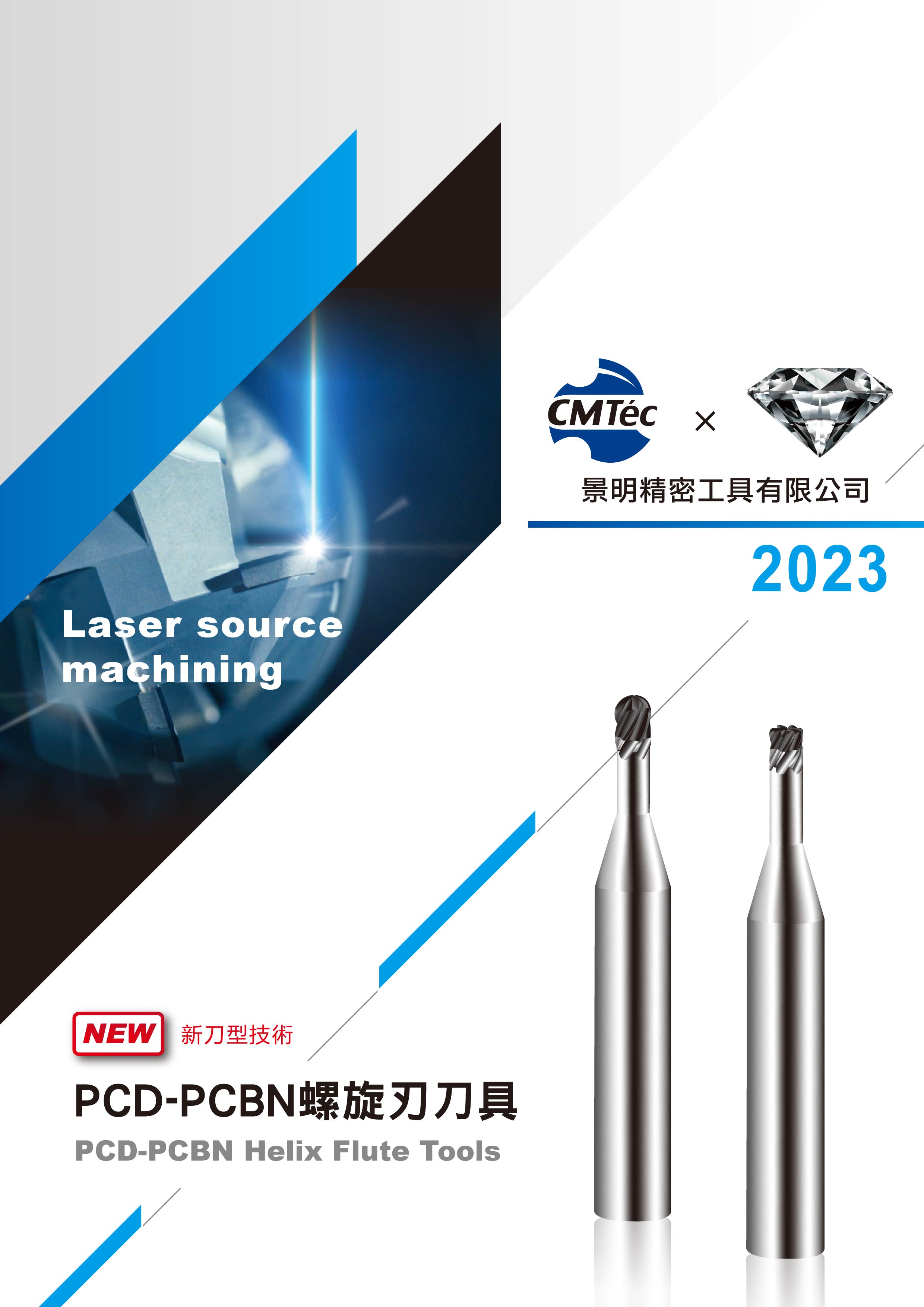

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.

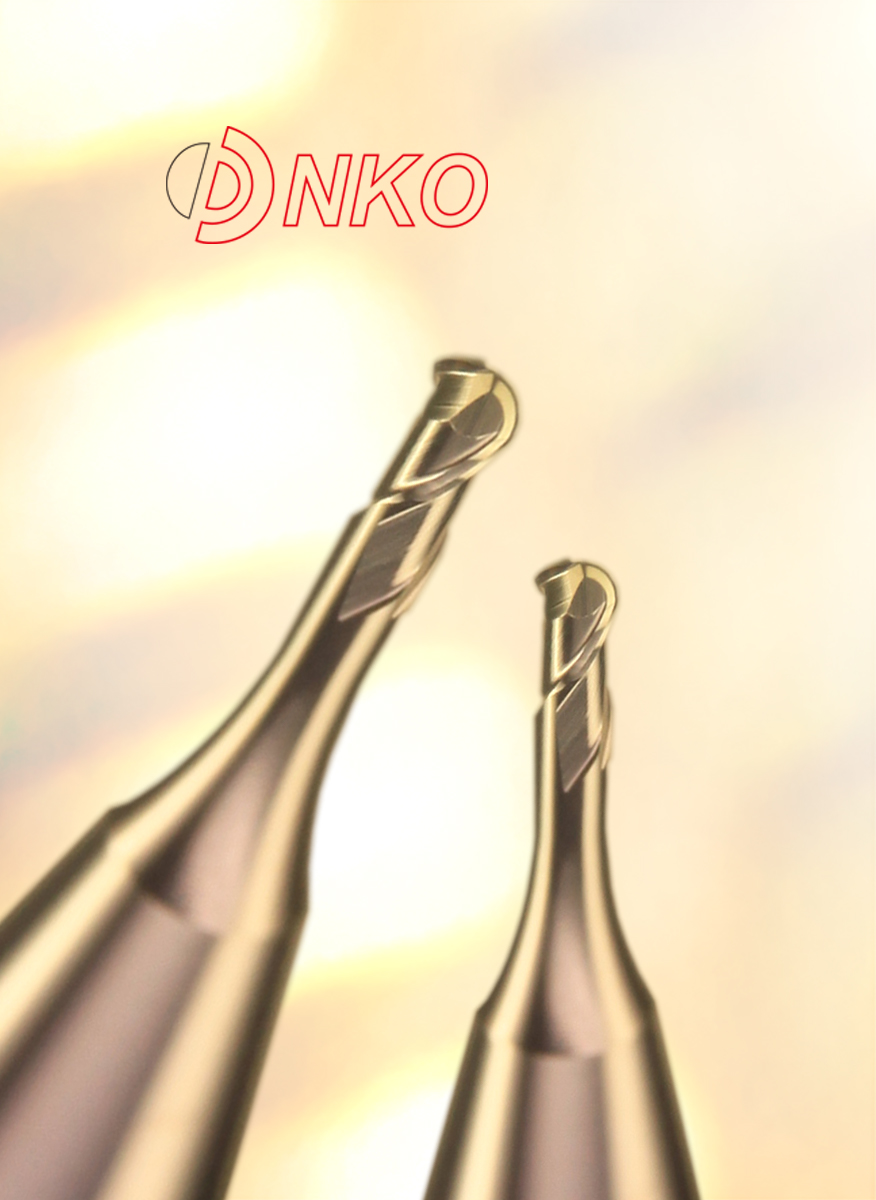

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.