展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ Single Crystal Diamond(Ultra Precision Cutting):

【CVD- HV8,000 ~ 10,000】

【MCD- HV5,000 ~ 10,000】

Work Material:Ceramic, Gold / Silver / Aluminum / Copper / Zinc / Magnesium Alloy, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Electroless Nickel, Carbide.

★ Polycrystalline Compound Diamond【HV6,500 ~ 8,000】:

Work Material:Ceramic, Aluminum / Copper, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Carbide.

★ Polycrystalline Cubic Boron Nitride【HV3,000 ~ 5,000】:

Work Material:Hardened Steel(HRC45~65°), Powder Metallurgy.

7-LEADERS CORP.

製品の説明 :

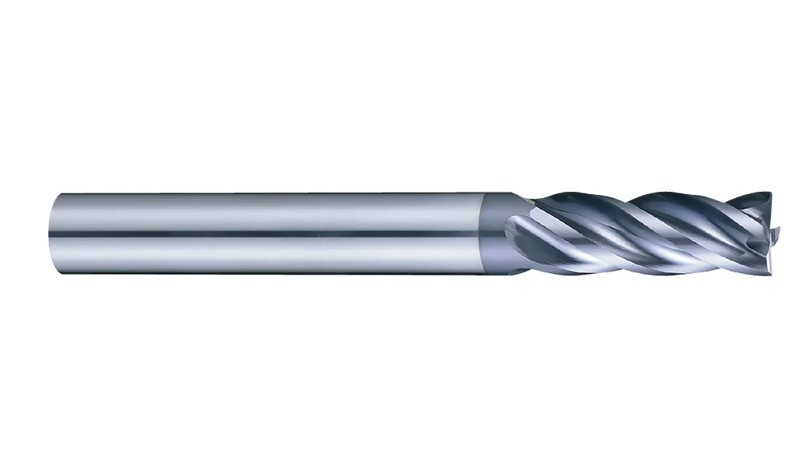

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.

VISION WIDE TECH CO., LTD.

製品の説明 :

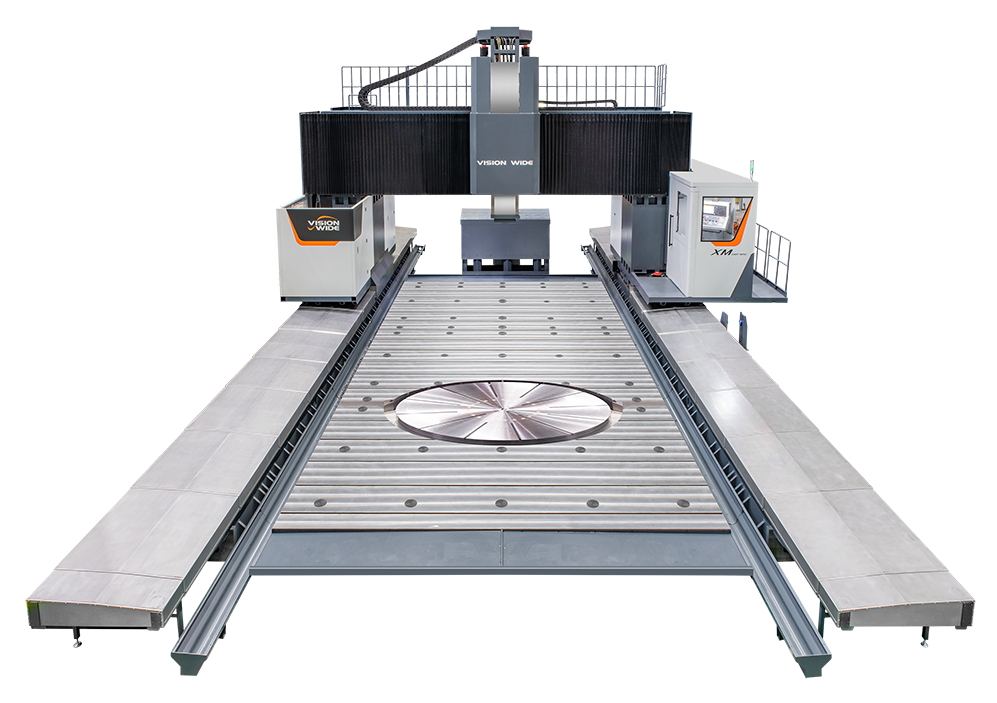

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

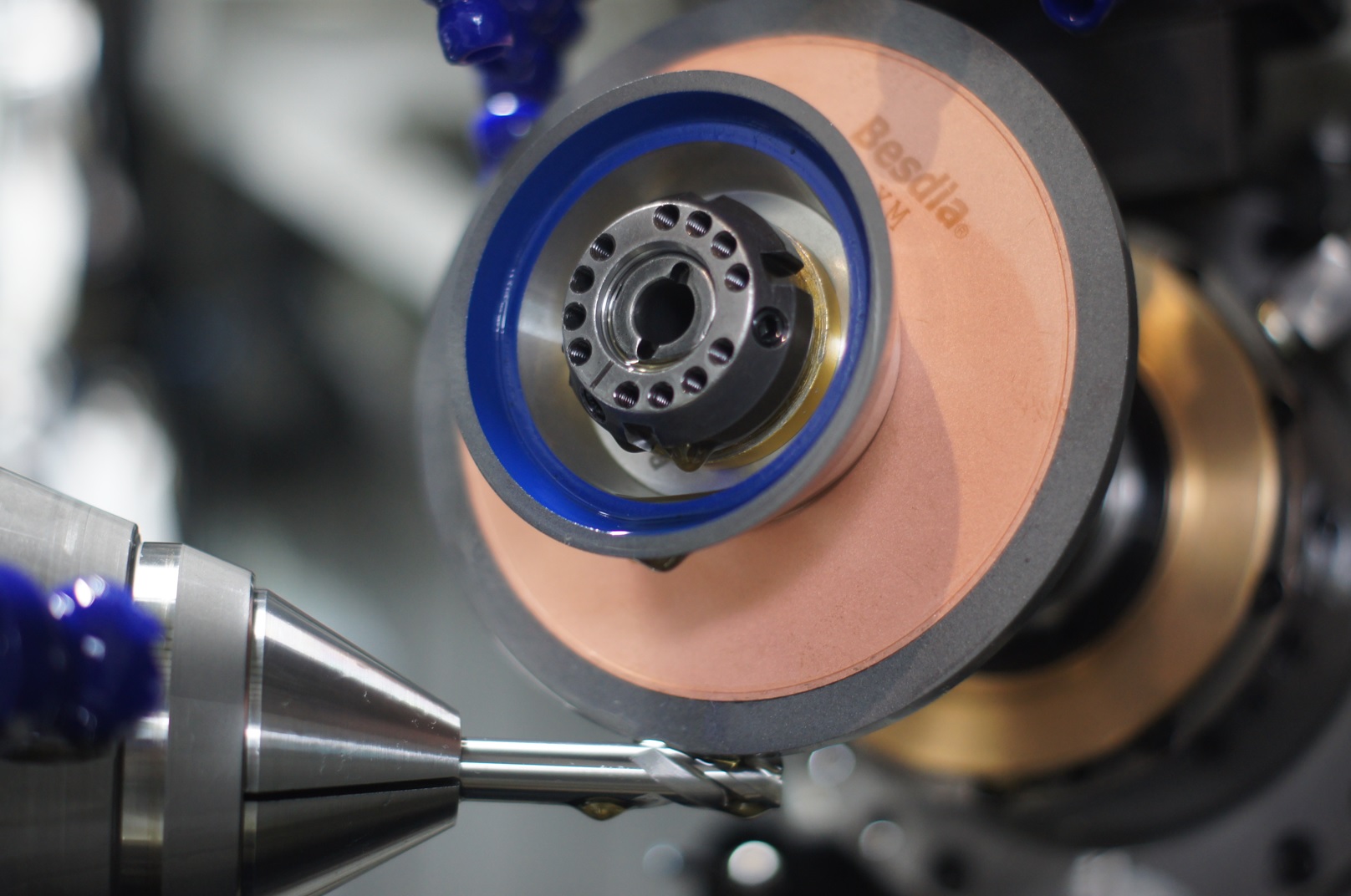

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

7-LEADERS CORP.

製品の説明 :

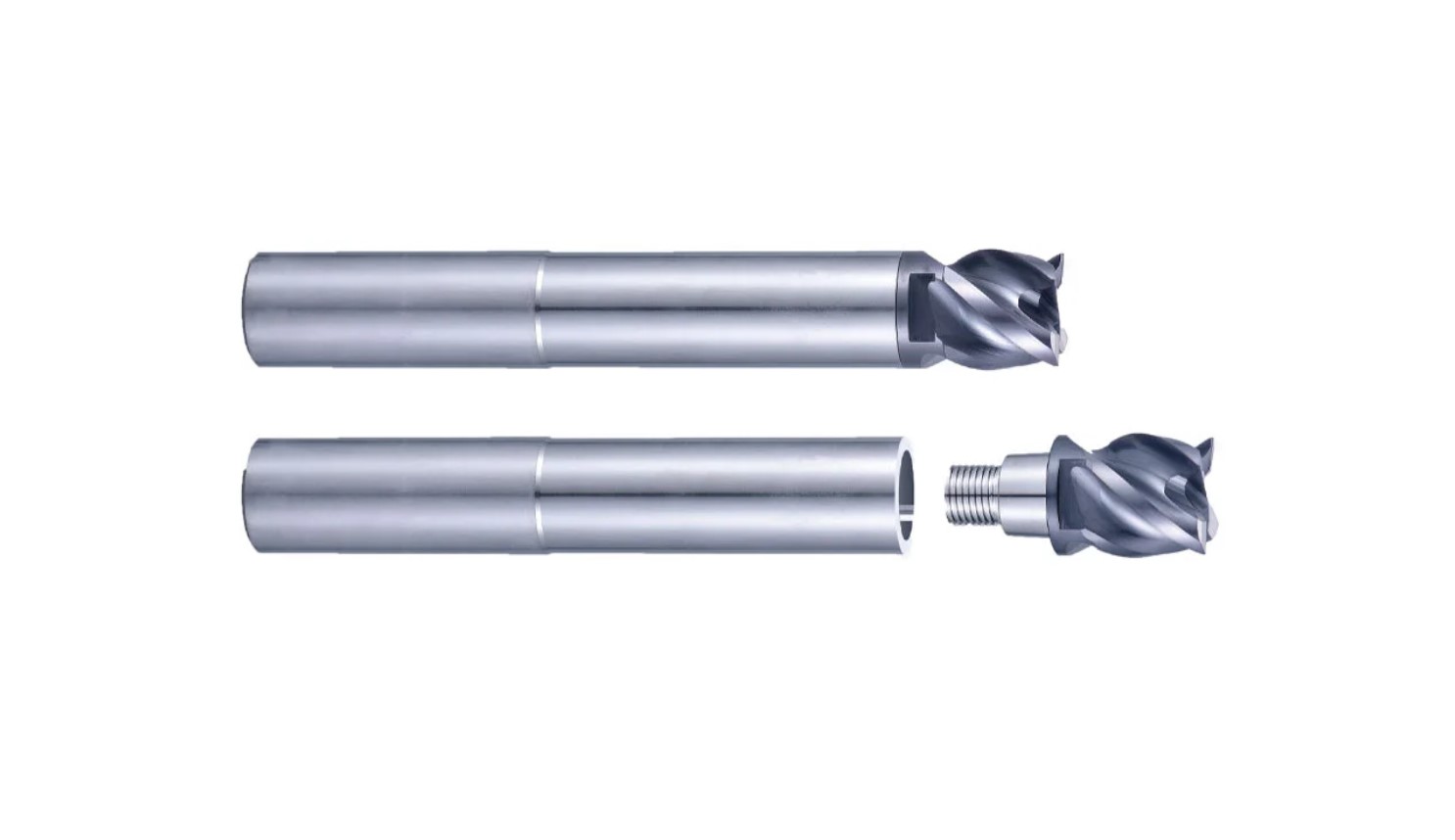

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.

7-LEADERS CORP.

製品の説明 :

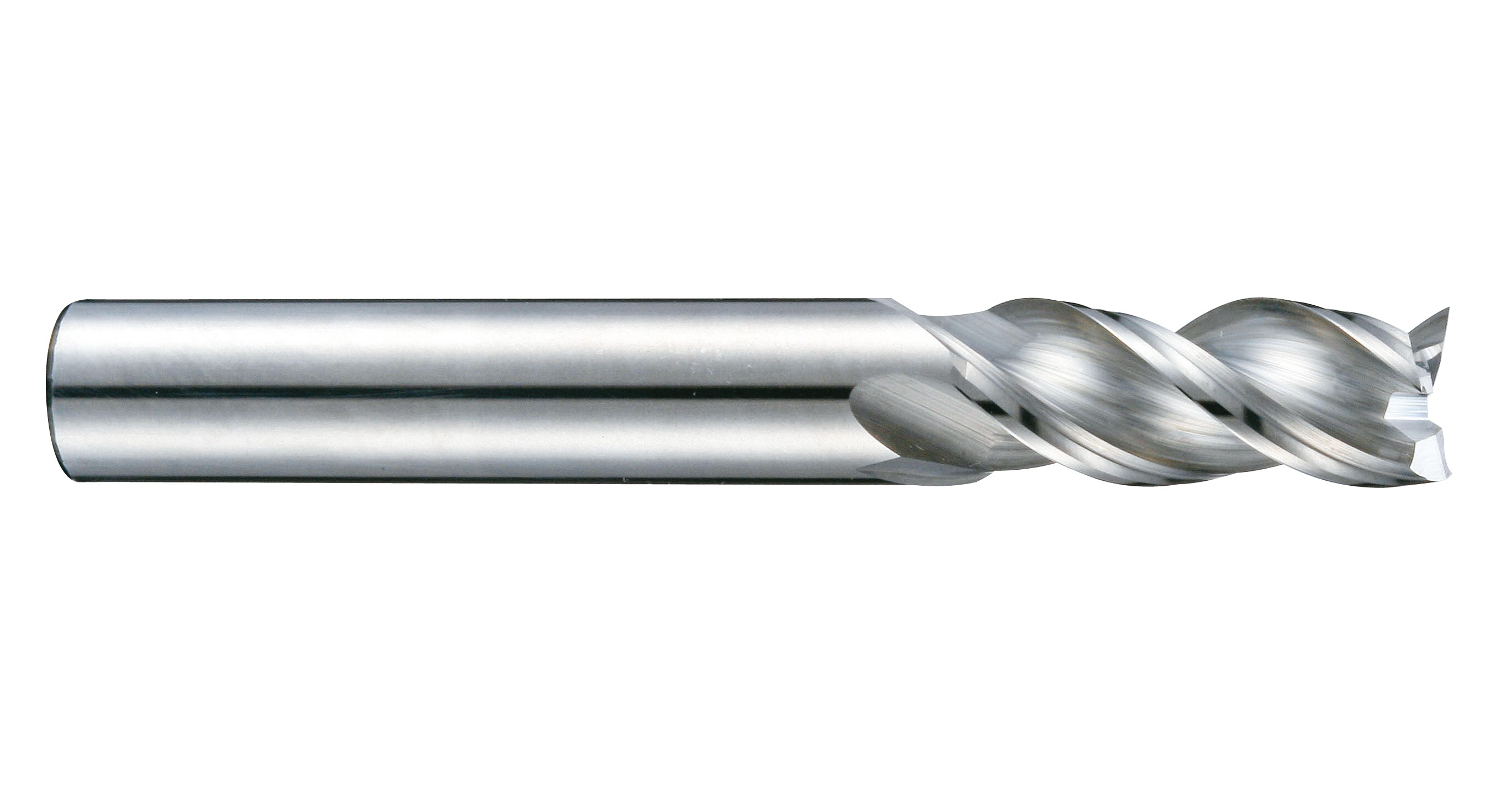

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.