展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

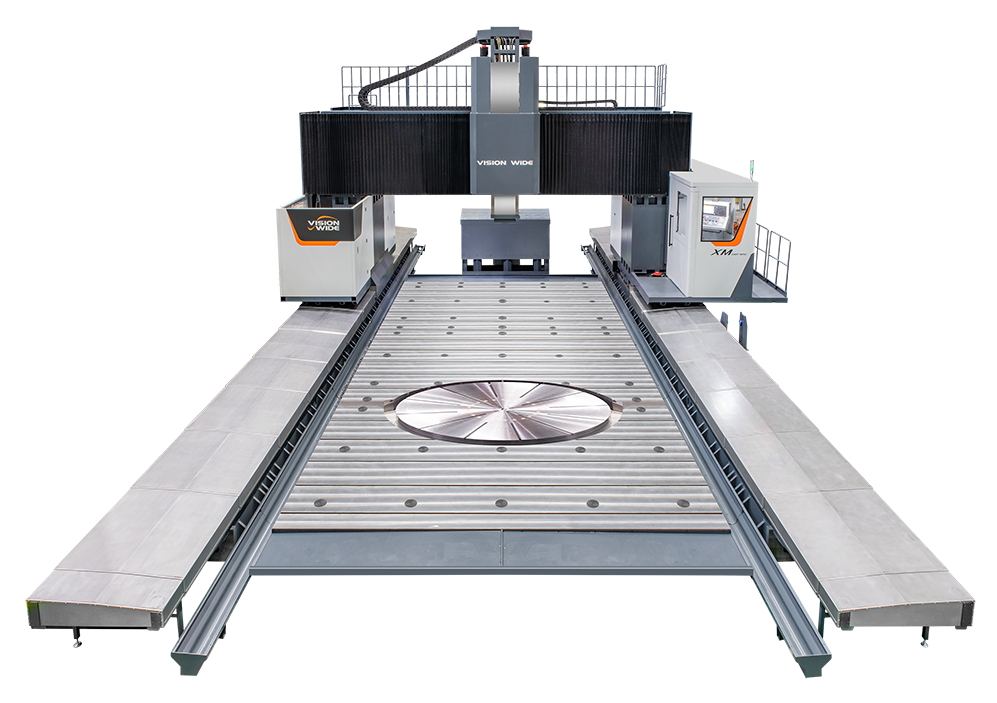

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

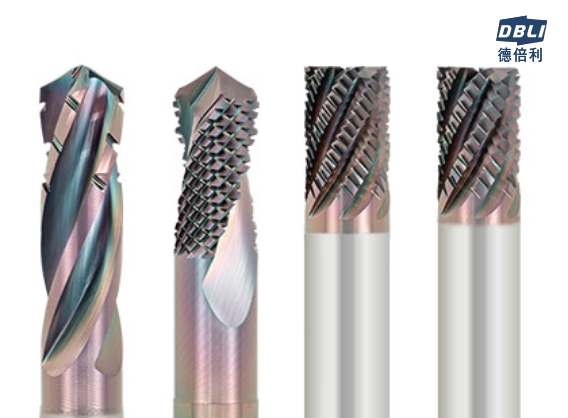

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1.With excellent features of coating to increase the tool life and wear resistance performance.

2.With unique geometry to effectively remove fabric residue.

◆Cutter Speialized in Cutting Fiber End Mills:

Patented flute shape/new design.

◆Cutter Specialezed in Cutting Fiber Drills:

Excellent performance in drilling burrs and tearing.

◆ Cutter Specialized in Cutting Fiber Drill End Mills:

Suitable for thru hole machining.

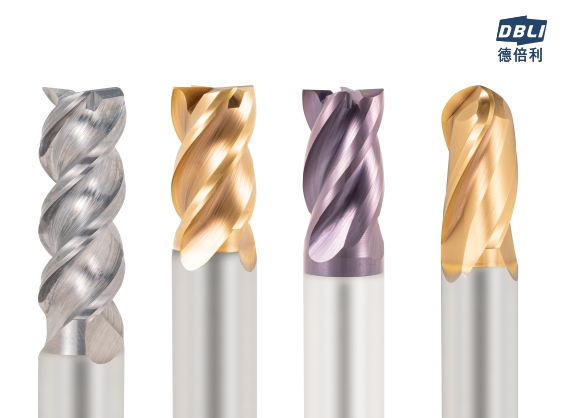

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

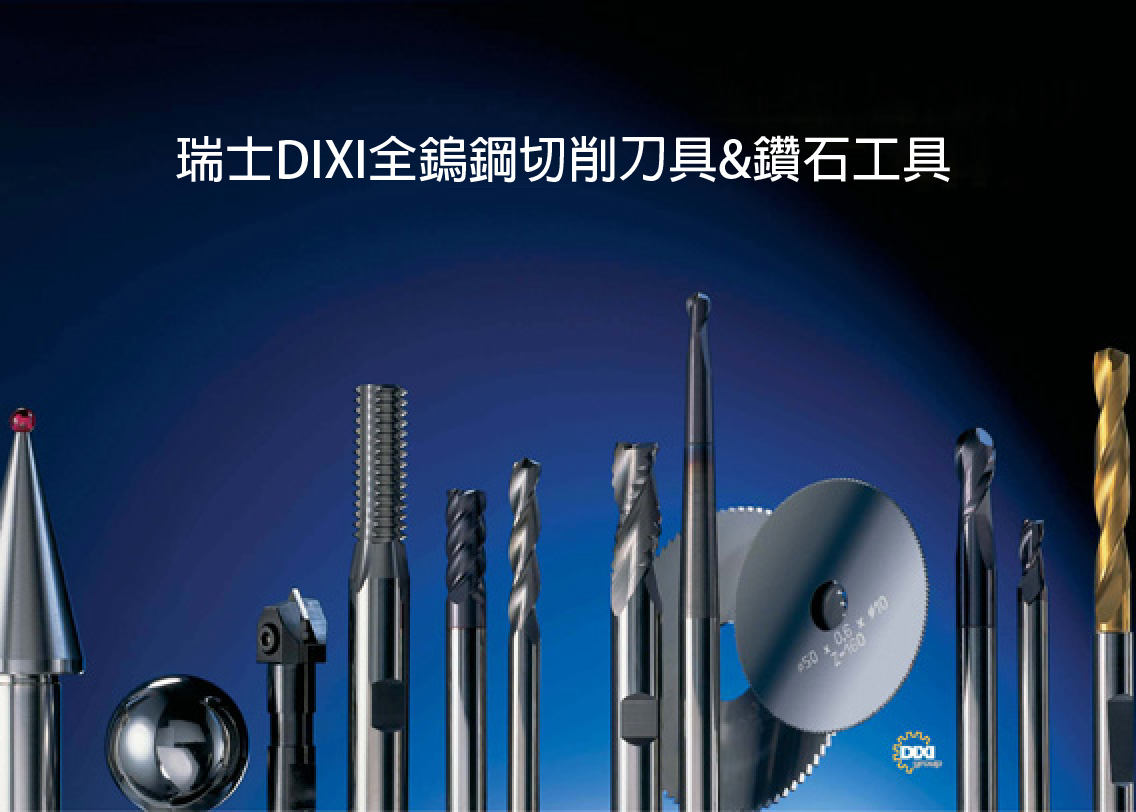

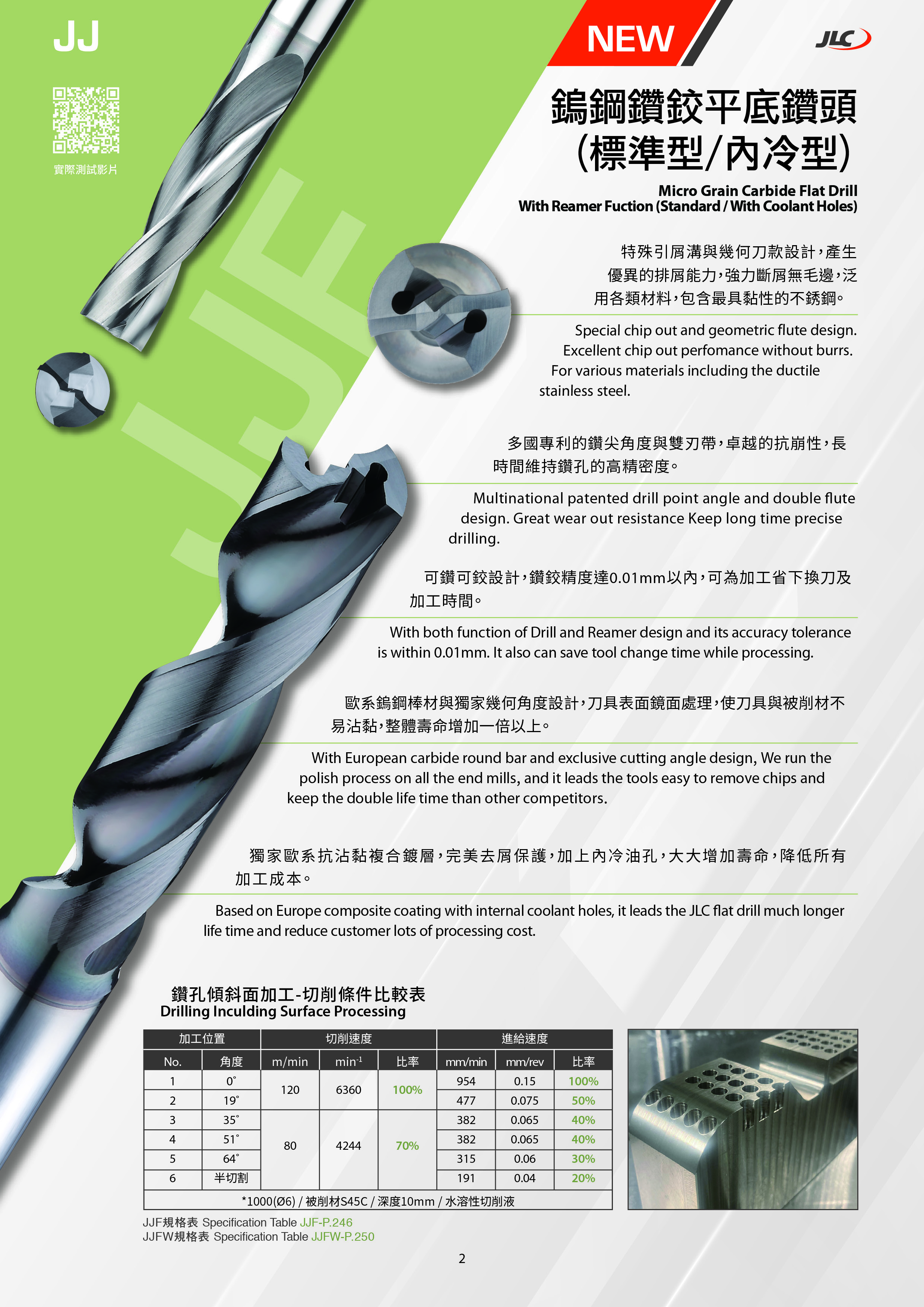

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

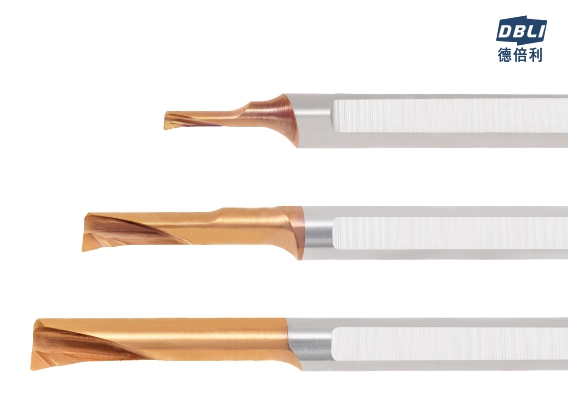

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. With excellent features of coating to increase the tool's wear resistance and thermal conductivity to reduce the chip residue problem.

2. Use special flute design to decrease the chip-off problem during machining.

3. Increase machining accuracy and surface roughness.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

Using powder metallurgy HSS is suitable for high hardness material tapping and stability of the tool life. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend tool life. TiCN coating provides welding and wear resistance ,which can lengthen the durability of taps. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend the tool life. TiCN coating provides welding and wear resistance, which can lengthen the durability of taps.

HP-NRT series include standard type(HP-NRT), and short chamfer type(HP-SC-NRT).