展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TAILIFT CO., LTD.

製品の説明 :

全新推出ES-27全電伺服轉塔式沖床,採用全電系列AC伺服數控系統,具有高速、節能、高精度與低噪音的特色,加上過負載自動保護設計,是沖壓高精密薄鈑件的利器。它的集成式組裝方式,有效減少地面安裝空間。因具有沖孔、成型、滾切與攻牙等多功性能,可減少無效率工時的等待,大大提升加工效率。

另外節能方面,平均耗電顯著降低,無液壓油的消耗,是環性保護需求的綠色產品,這也是機身基座採O型龍門式架構設計,經世界級頂尖實驗室使用結構有限元素分析後,完成機身機座各部結構之靜性結構分析、剛性結構分析、暫態分析等應力結構性資料。

在構造機身基座之材料上,選用高強度鋼材焊接,引進尖端熱處理技術,消除焊接產生的熱內應力,使機身金屬結構完成統一機身機座,在精加工前更再經過高張力測試、正常化處理與震

動應力消除等三道防線嚴格把關,使機身組裝精度維持一致性。

HONG JI PRECISION MACHINERY LTD.

製品の説明 :

Drilling capacity is from Ø5mm to Ø40mm and the max. drilling length is 3000mm

The machine is suitable for drilling accessories of petroleum system, tube holes of heat-exchangers, long mechanical sleeves and long aerospace parts.

Slideways of all axis are harden box ways with heat-treatment to HRC52, this design has good damping to absorb vibration as drilling big and long holes.

The worktable is loaded on the harden box slideways with width 200mm. The max. loading weight on the worktable is 20tons.

The width of column is 2 meters with two sub-columns to provide the excellent support to Y-axis as moving up and down. Total weight of the machine is about 38tons.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

GT MARKETING Co., LTD.

製品の説明 :

Strategy-Based, Driving Brand Development:

We carry out brand development based on strategic thinking, starting from industry research and analysis, proposing decision-making basis, digging out the most suitable brand positioning, and solving business problems with design thinking. We recruit cross-field talents to assist companies in integrating brand market communication, marketing exposure planning, and visual design to achieve sustainable brand development.

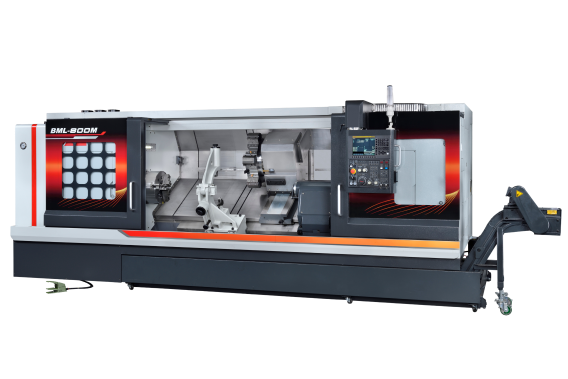

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GO-354 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-354 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

G-TECH INSTRUMENTS INC.

製品の説明 :

★Multi-Channel Dynamic Measurement: 4-CH simultaneous analog input, compatible to accelerometer, microphone, etc.

★Digital Data Processing: Local real-time computing, data storage, and transmit to data center via ethernet.

★Test & Measurement : Remote Mode--FFT Analyzer;Standalone Mode--Data Recorder & Transmitter.

★Condition Monitoring: Programable multiple I/O interface, connect to controller for intelligent manufacture.