展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

BORE AUTOMATION TECH. CO., LTD.

製品の説明 :

Cable Assembly for PLC, Standard type, 25AWG tinned copper wire, high quality SCSI Soldered connector , 50 cores, 2 meter length

EUMACH CO., LTD.

製品の説明 :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

HYDROKOMP GmbH

製品の説明 :

Swing clamp cylinders release the clamping point on the workpiece. With this, it is easy to change the workpiece. This hydraulic swing clamp cylinder operates as single-acting or double-acting traction cylinder, whereas part of the stroke is used to rotate the piston. The model with 0° swing angle operates only vertical as traction cylinder.

To guarantee a long lifetime the cylinders have an integrated metal wiper as standard. For oil supply, the cylinders are equipped with threaded port and manifold port with O-ring for drilled channels. You can select between right or left turning models with various standardized swing angles. The integrated overload protection protects the swing mechanism from damage due blockage of the rotation or improper assembly of the clamping arm.

For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line. Counter-hold the clamping arm when tightening or loosening the counter nut in order to prevent torque transfer to the piston rod and to avoid damage to the ball guide. Variations with 0°, 30°, 45°, 60° and 90° swing angles are available. The permitted operating pressure is depending from the clamping arm length.

TANKO ENTERPRISE CO., LTD

製品の説明 :

► Top tray for CNC tools

► 4"x2" PU casters with total 1000kg loading capacity

► T represents T drawer

► Normal Drawer: 90% extension with 100kg loading capacity

► T Drawer: 100% extension with 200kg loading capacity

► Drawer front height lower than 200mm with standard dividers

► Drawer front height over 300mm with CNC tools holder tray

► Full length aluminum handles with patented safety lock system

► Interlock system

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

CENTURY TRADING CORPORATION

製品の説明 :

高性能

● 高速、高精度、高功率

● 穩定加工

● 廣泛的應用範圍

高效率

● 高可靠性

● 充實的預防維修功能

● 便於保養維護

易操作

● 優異的操作性

● 高擴展性

● 自動化對應

PRECISION MOTION INDUSTRIES, INC.

製品の説明 :

Achieved the high-precision motions, lifting, rotaty, as well as quick grip motion in confined spaces.

Features

•High Positioning Accuracy

•Lightweight and Compact

•Simple Installation

•Support Bearing

•Smooth Motion and Lower Noise

Application

SCARA robot, Assembly robot, Automatic loader, and Machining center's, ATC equipment.

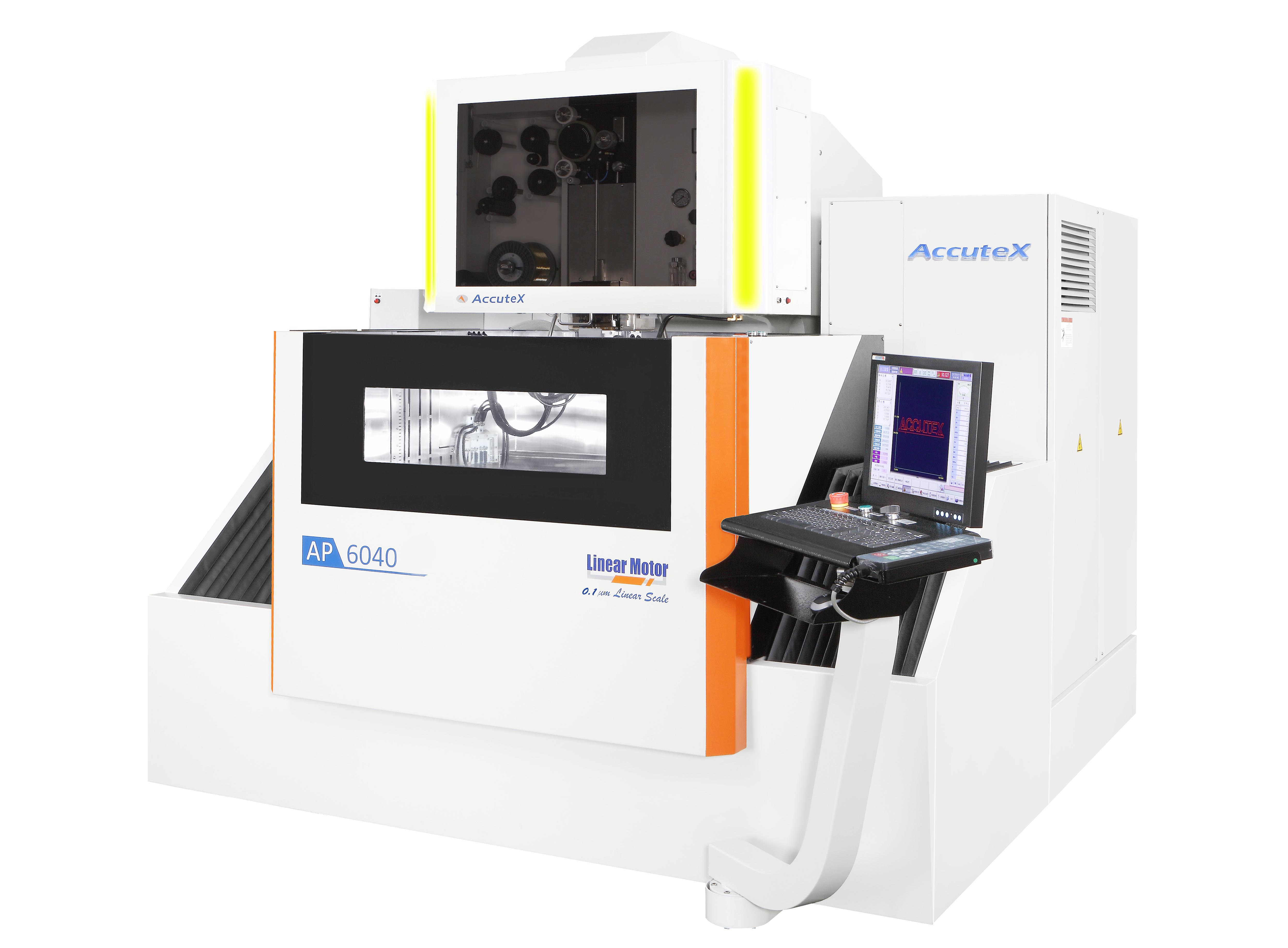

ACCUTEX TECHNOLOGIES CO., LTD.

製品の説明 :

AccuteX machine is capable with industry 4.0 who has M2M (machine to machine) protocol

to collaborate with Robots and other machines. Flexible Real-time production can be made

by Intelligent Manufacturing Integration System to meet full-automation demand.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

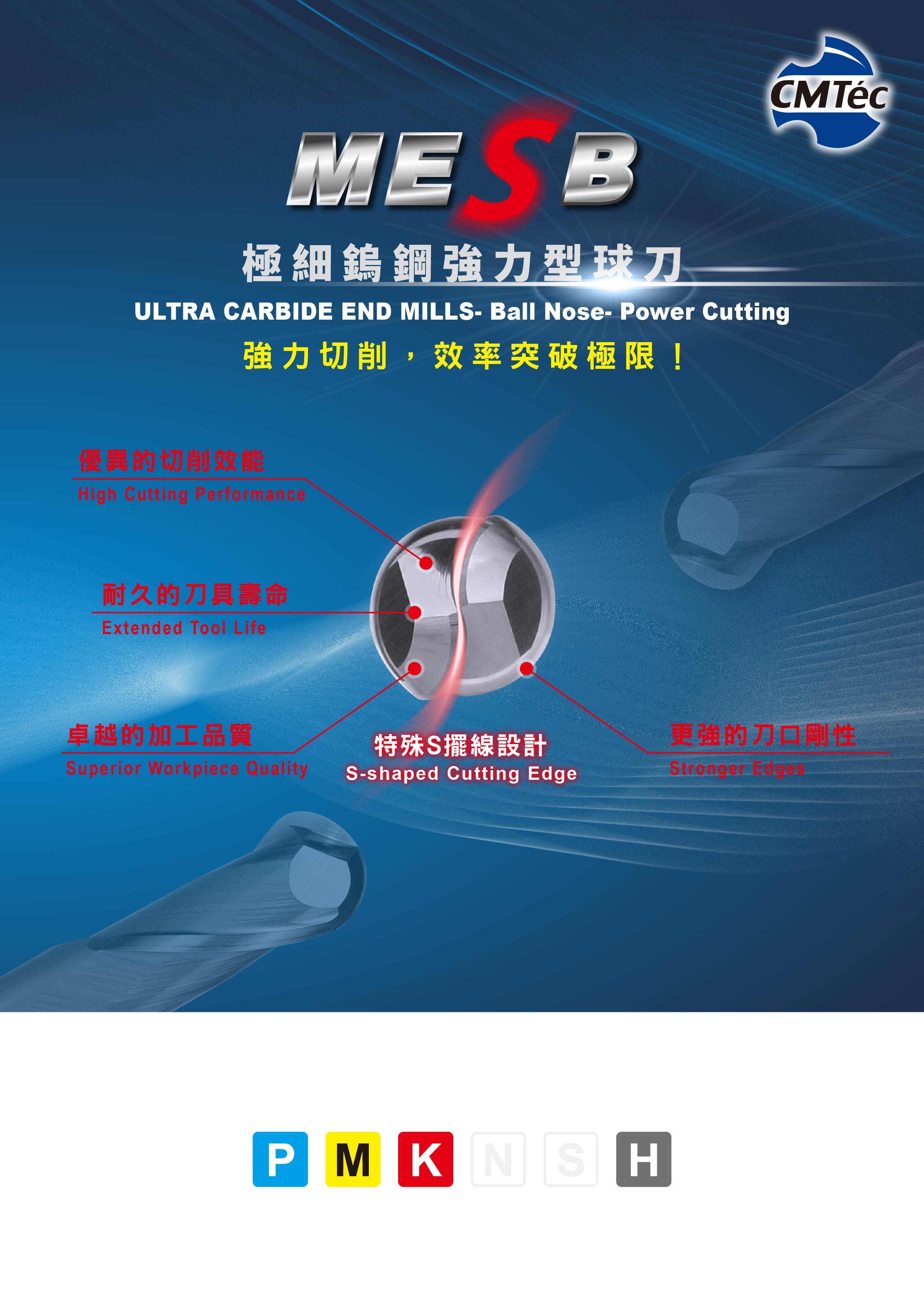

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ Cutting edges and workpiece reduce contact area, lower cutting resistance and boost efficiency.

★ Cutting edges distribute cutting forces evenly, reducing wear and extending tool life.

★ Minimizes vibration during machining, improving surface finish and precision.

★ For copy milling alloy steel, hardened steel (≦60°HRC), stainless steel and cast iron.