展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

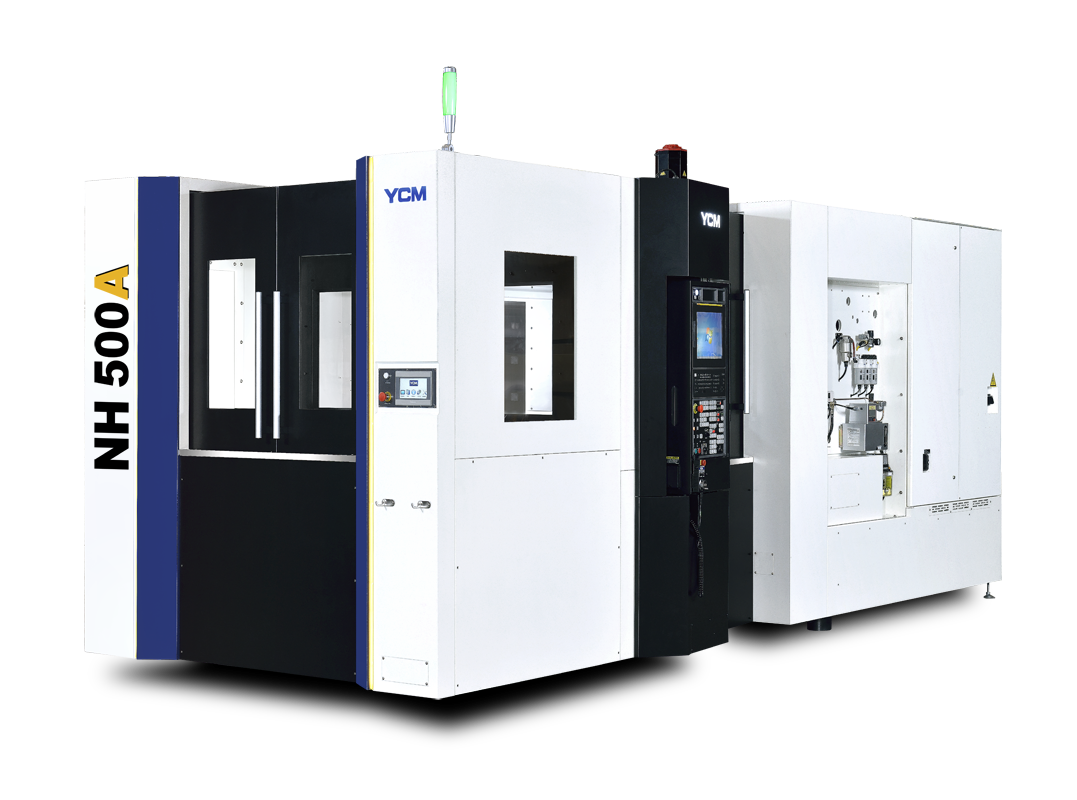

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

High rigidity and high accuracy NH500A provides the best solution for automotive, precise and mechanical parts industries.

■ High rigidity T-base foundation with rib construction

■ One-piece casting spindle headstock and dual-wall column design

■ Powerful Built-in spindle with Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life

■ High precision roller type guideways on all axes

■ High precision pallet indexing system.

TORNG INDUSTRIAL CO., LTD.

製品の説明 :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

MONGTEC PRECISION INC.

製品の説明 :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

A Being Kou Tools Co., Ltd.

製品の説明 :

After becoming frustrated by the existing coolant hose products on the market; all of which suffered from a variety of shortcomings, Arnold Lockwood conceived the idea for the modular hose that became Loc-Line®. The shortcomings of the existing products included, metal coolant hoses that would not stay where they were positioned and plastic hoses with metal positioning rods that broke.

In 1981 Lockwood Products was formed to develop and distribute Loc-Line®. The first products were shipped in August of 1983.

Loc-Line® quickly became the standard for coolant delivery around the world and was easily recognized by our Blue and Orange colors and consistent high quality.

Today Loc-Line® is still the leader in modular hose and continues to innovate in the modular hose field. Loc-Line® is used not only as a coolant hose but for air delivery, smoke and dust removal vacuum systems, agriculture, third arm uses including positioning cameras, lights and items for handicap assist.

We here at Lockwood Products, Inc are proud to have originated the modular hose Loc-Line© that remains the standard for the industry worldwide!

Please visit one of our distributors today and see for yourself why Loc-Line remains the best and most versatile solution in the world today!

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

製品の説明 :

1. Fixed amount of oil feeding that can supply the required amount of oil to each lubricating point.

2. There are various choices of discharge volume, 0.1, 0.2, 0.3, 0.4 and 0.5cc per stroke. The discharge volume of each outlet can be different.

3. Each discharge outlet has a detective piston that can detect if the pipe system works functionally.

4. T type 0.5cc can be assembled either NO (Normal Contact) or NC (Normal Close) Contact sensor switch. It also can be set up as NO or NC Contact upon request. When it is set up as NO Contact, it sends signal during the operation time. When it is set up as NC Contact, it sends signal during the interval time.

5. T type volume distributors accumulate oil inside of the distributor and discharge oil during the interval time.

6. T type volume distributors have to work with oil pressure-relief type lubricators. The lowest operation pressure is 8 kgf/c㎡ and the max pressure is 30 kgf/c㎡.

7. The viscosity range of oil is 32 ~90 cSt @ 40℃.