展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURE:

Six particle size channels : 0.3m, 0.5m, 1.0m, 2.0m, 5.0m, 10m

Integrated temperature / humidity sensor (no need for external add-on).

Flow rate 2.83 L/minute (0.1 CF / minute).

Rechargeable battery provides up to 4 hours of continuous operation (charge time 2.5 hours).

Buffer function allows storing and redisplay of up to 500 measurement data sets.

SD storage device.

APPLICATIONS:

Monitoring clean-rooms, manufacturing processes and pharmaceutical production.

Indoor Air Quality (IAQ) monitoring.

Monitoring gowning rooms.

Testing filter seals.

Locating particle contamination sources.

Monitoring particle size distributions.

ASMITH MANUFACTURING COMPANY

製品の説明 :

High precision, durability, stability electronic torque wrench, torque range of 0.1~1000 Nm, accuracy guaranteed ±1%, MIT, Japanese specifications wafer can use 20 years. Factory measured 100000 times to lock still keep high precision. Suitable for metal machine tool, controller & computer system, precision industry, high tech & electronic industry, quality assurance & manufacturing dep. |Tube Material:Medium carbon steel|Grip Material:ABS|Series: Standard Electronic Torque Wrenches, Mini Digital Torque Wrenches, Digital Torque Adapters, Open-ended Insert tools

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off

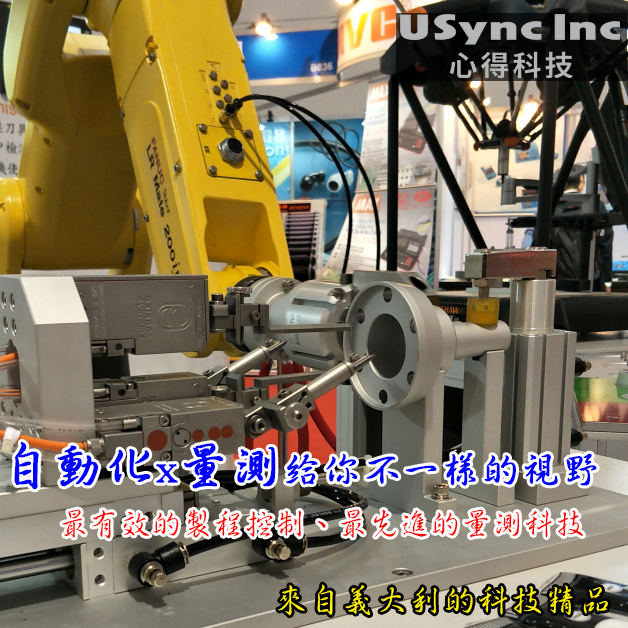

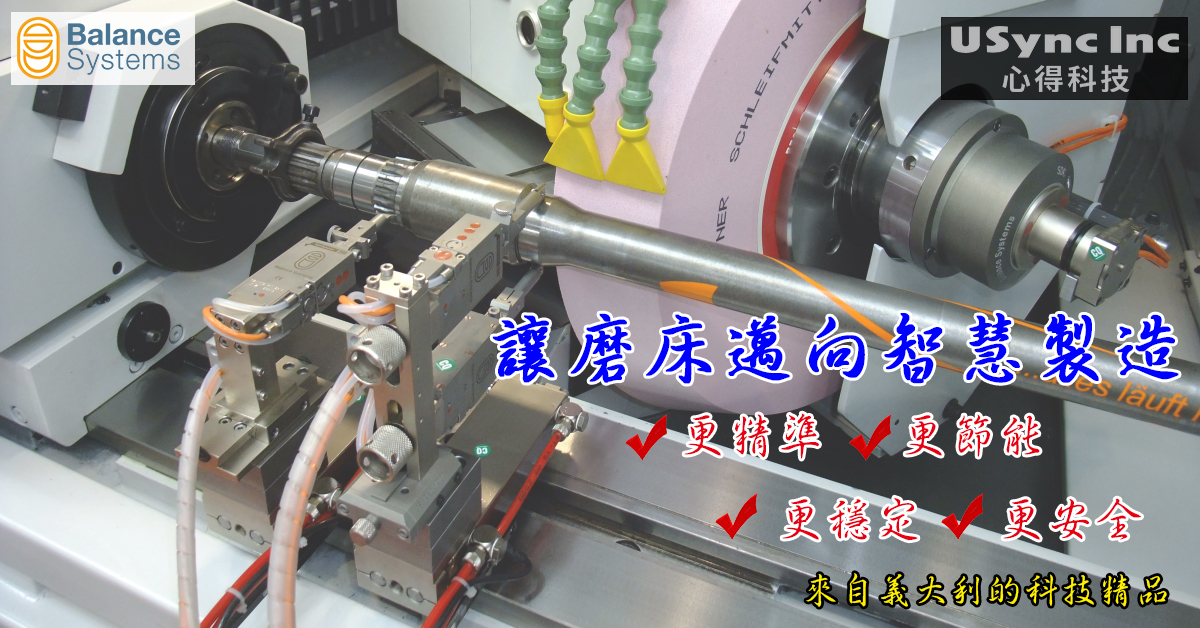

USYNC INC.

製品の説明 :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

G-TECH INSTRUMENTS INC.

製品の説明 :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

APACER TECHNOLOGY INC.

製品の説明 :

一機可檢測十種藥瓶樣式,使用新式旋轉夾具,全自動檢測無須更換治具;搭配多角度鏡頭360度拍攝,精準取像並加速檢測。雙中控台顯示與分料口設計,In-line方式配合產線進出料動線;結合自主研發AOI檢測軟體快速辨別並標示藥瓶的不良區,協助品管人員驗證更增進作業效率。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

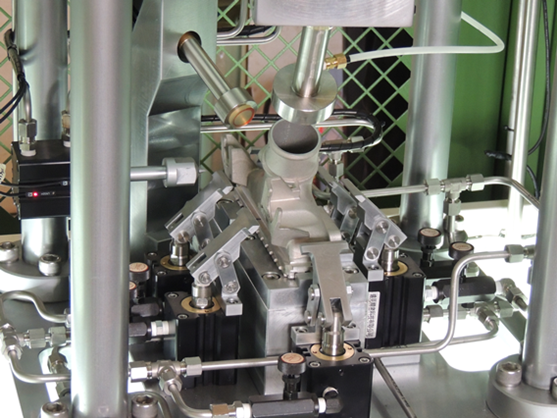

FARSIGHT PRECISION CO., LTD.

製品の説明 :

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS