展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.

7-LEADERS CORP.

製品の説明 :

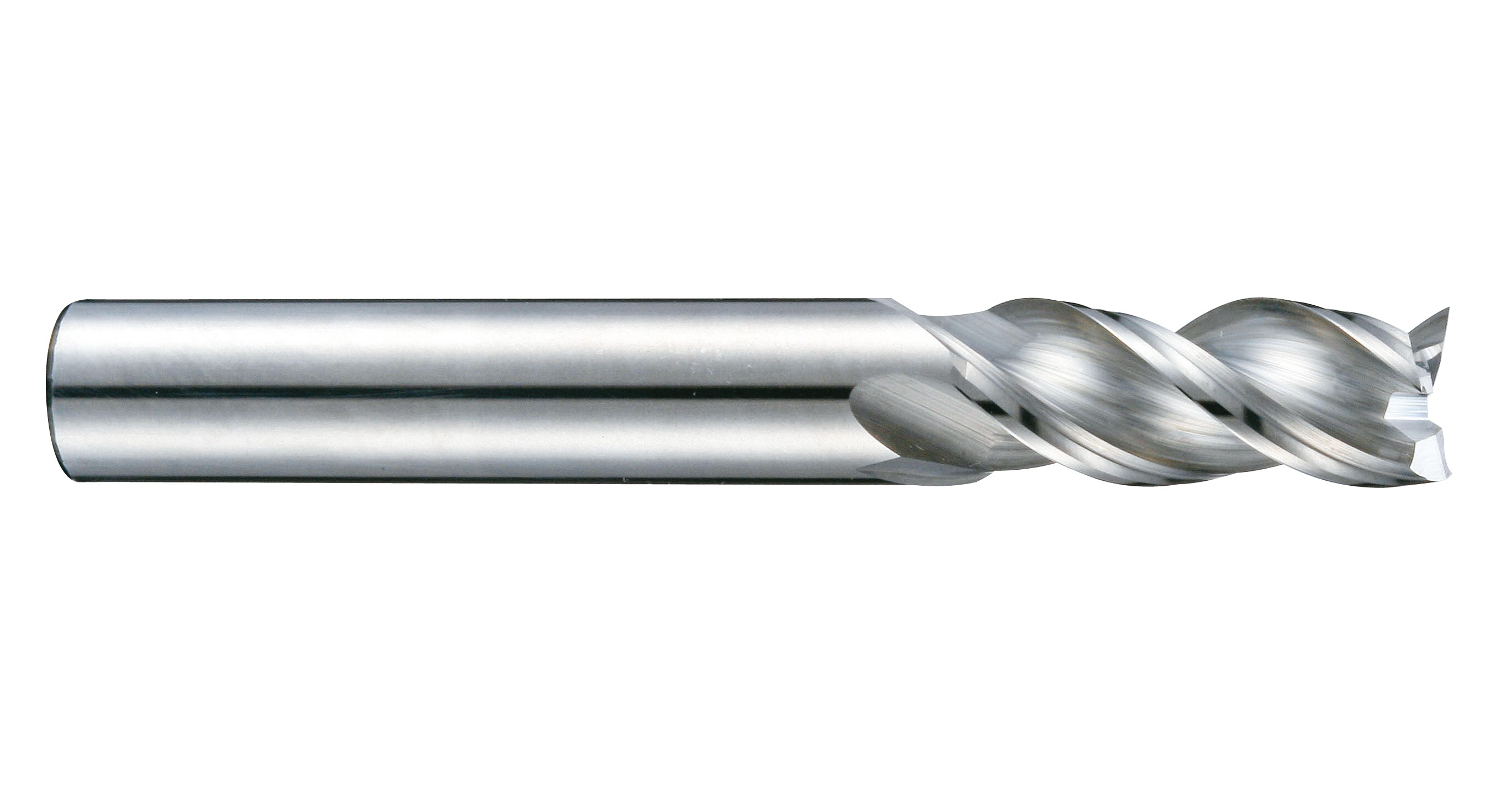

End Mills for Aluminium- 3 Flutes

Design with sharp cutting edge, high removal cutting geometry, and fine grinding smooth surface to prevent sticking problem.

Higher finishing of cutting edge to have better surface roughness after processing.

Application for roughing and finishing in various Aluminium.

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

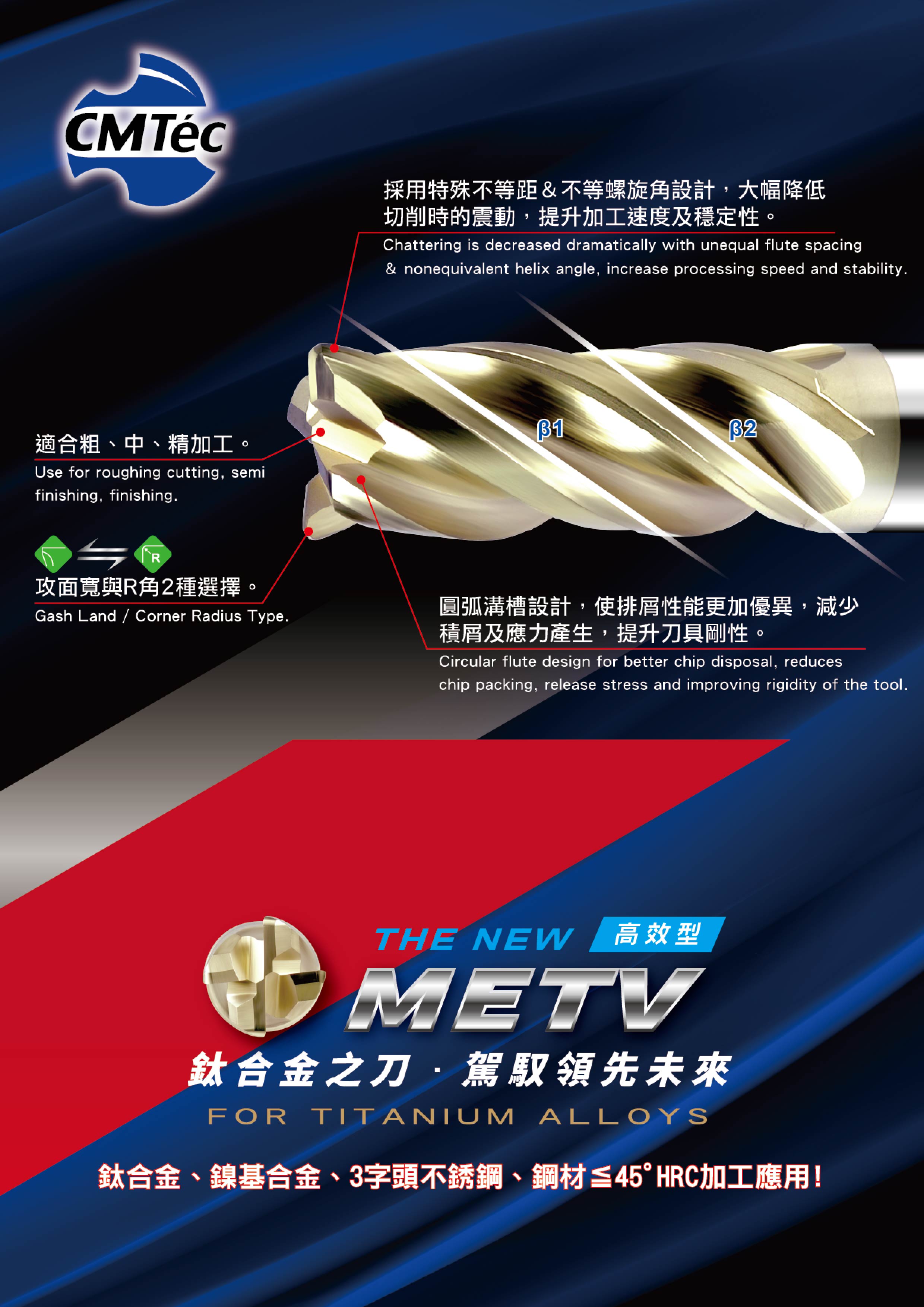

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

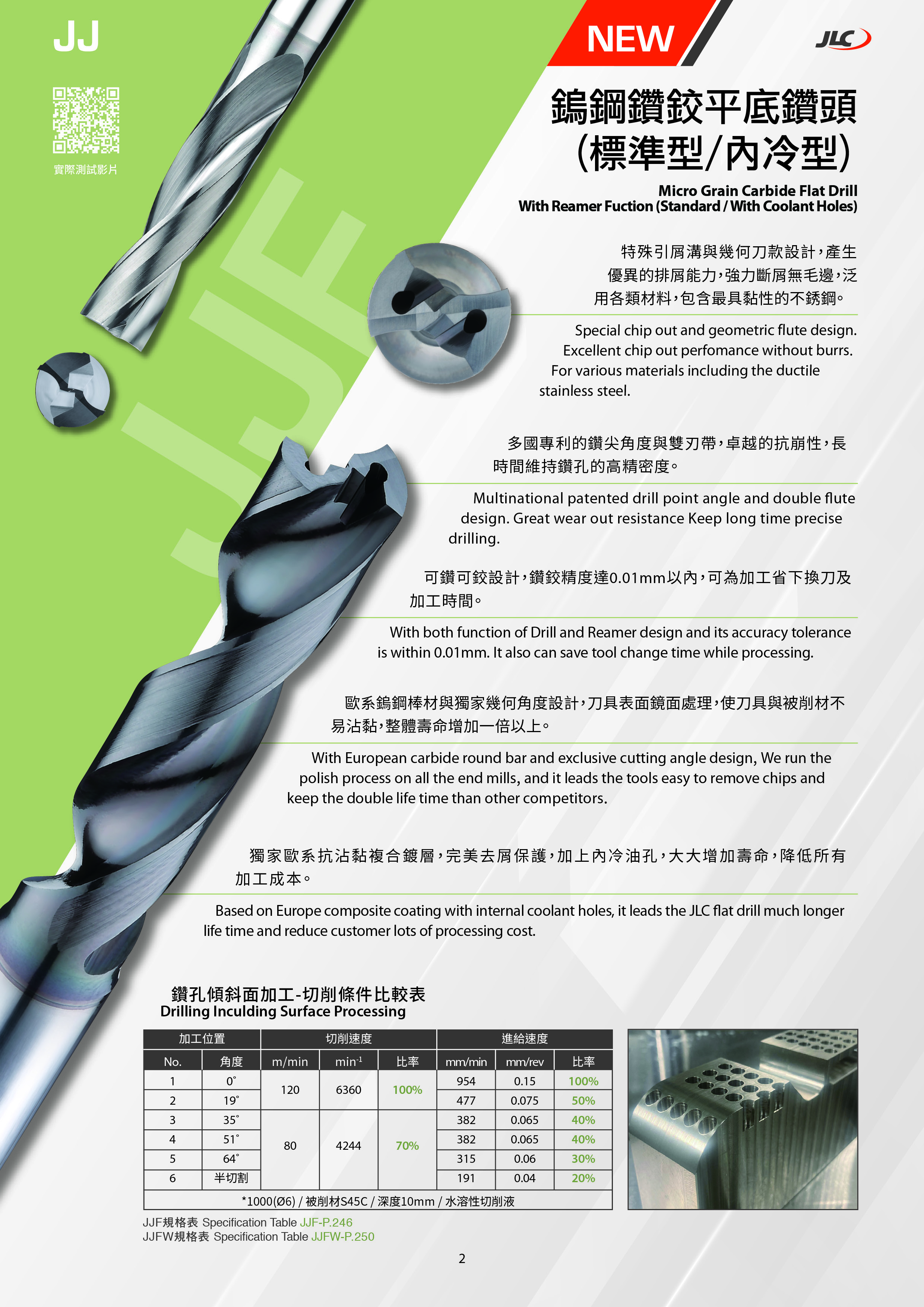

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

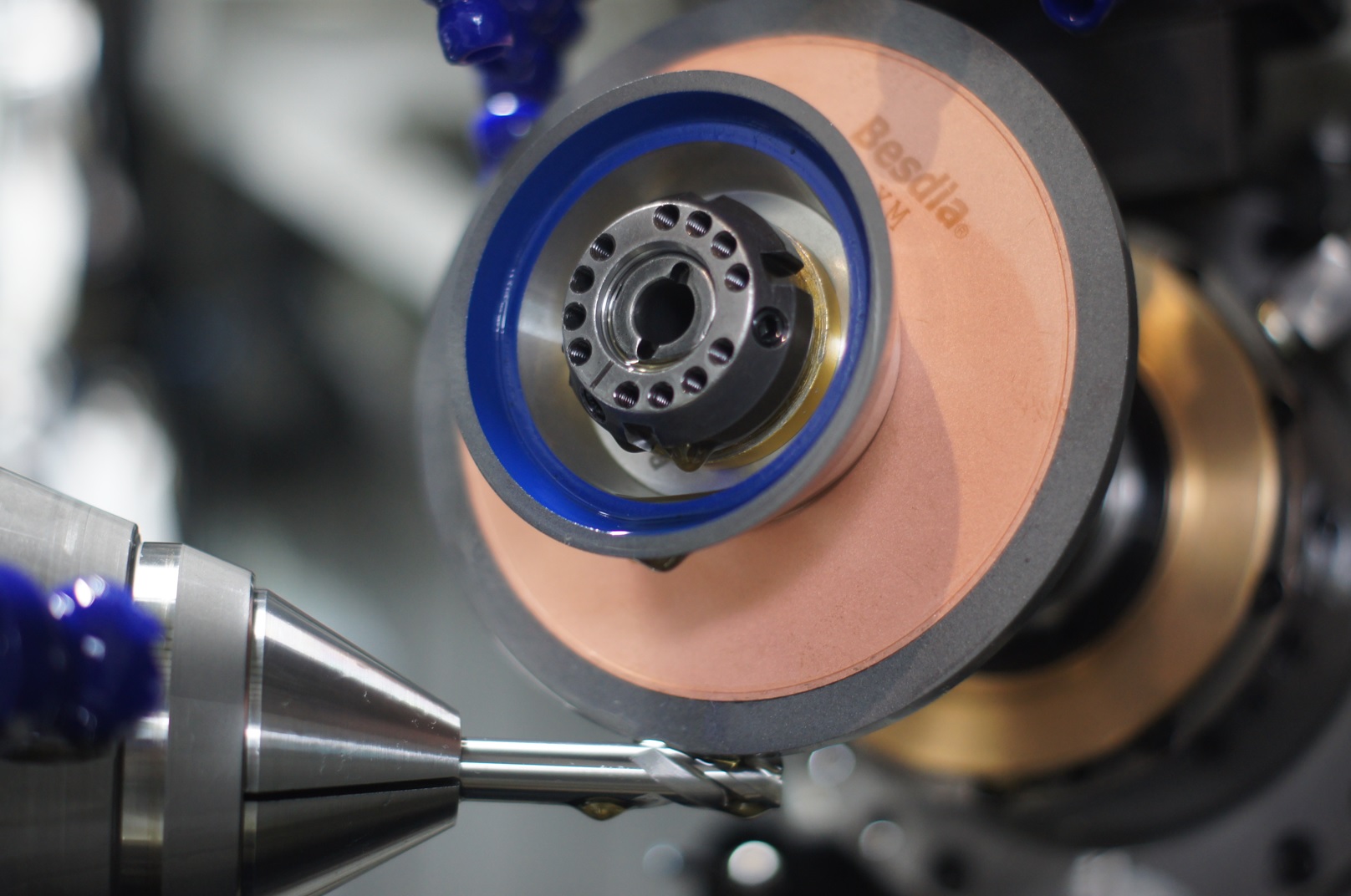

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.

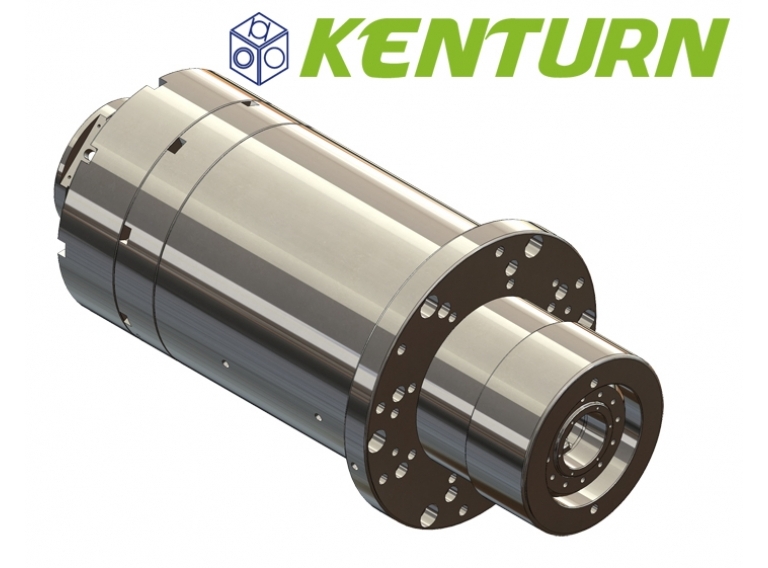

KENTURN NANO. TEC. CO., LTD.

製品の説明 :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

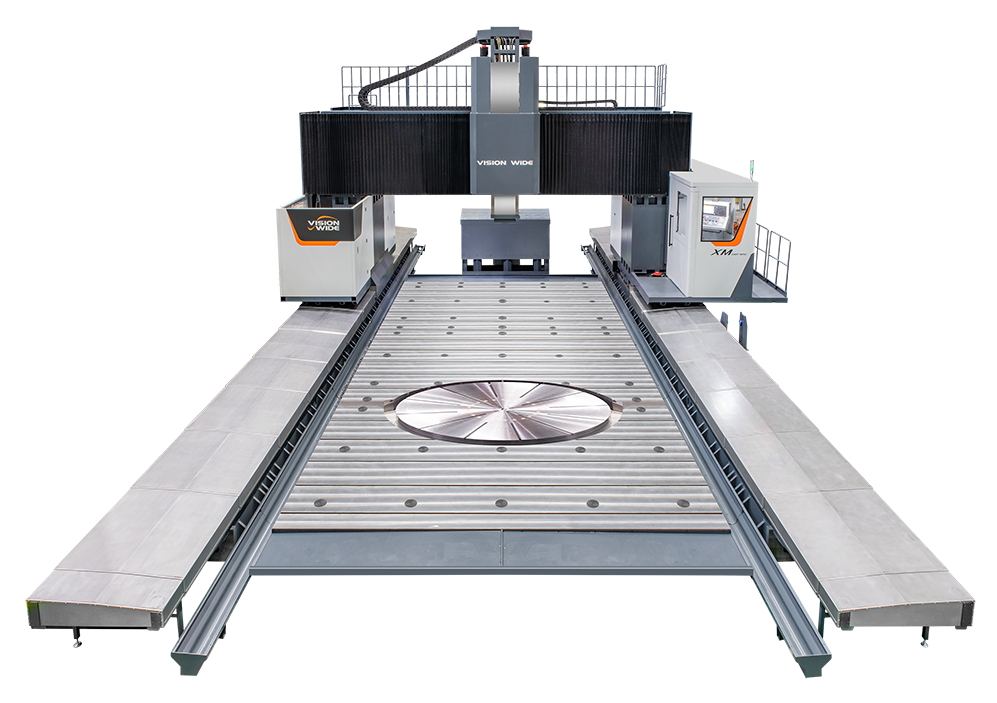

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.