Theme

Digital Transformation

Green Transformation

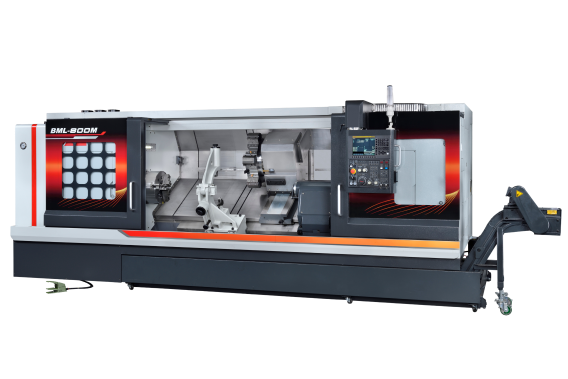

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

YK series is designed specially for small and high precision parts with powerful processing capacity, stable quality and accuracy. It is the best choice for various manufacturers of automotive and motorcycle parts, electronic parts, instrument parts and medical equipment parts.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

Product Description :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The Machine Center for next generation — TLV-850II

Applied field: general hardware processing, mold processing, precision parts

TLV-850II is known for its stability and capability of manufacturing with its high rigidity, which adopts the advantages from TLV-850. Furthermore, it applies the structure which fits the current trend.

-T-slot is used with the common specialization: 18mm

-Z-axis is adopted with the design of high rigidity, a bigger motor, and the strengthened structure so that it leads to perfect swarf performance.

-The tool magazine is well designed to provide the best stability.

-A stronger saddle and an enlarged base frame are also installed to stabilize the performance on cutting.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

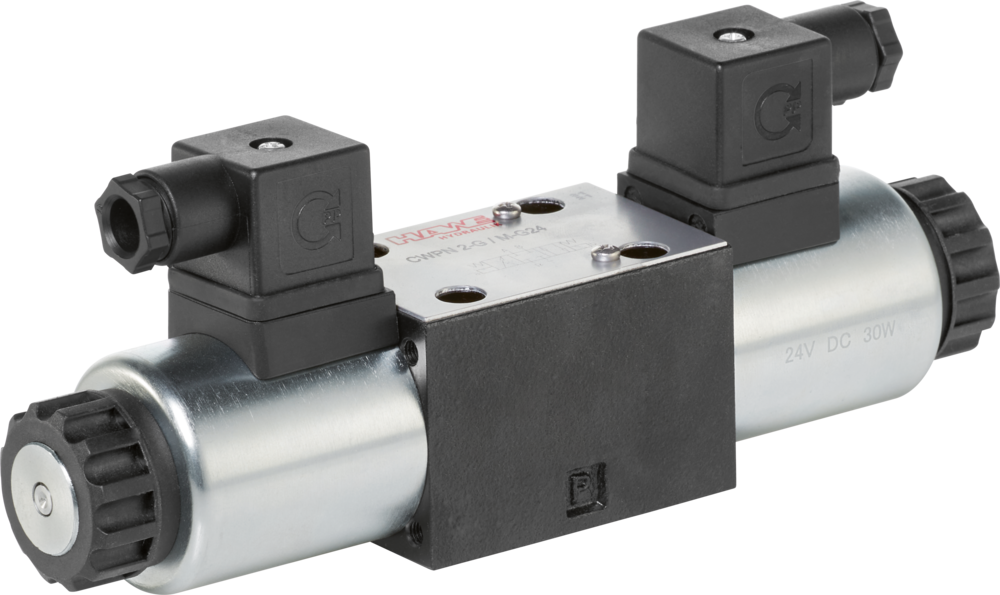

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The WTS series combine with double turret, double spindle and double Y axis. Both of 16-station power turrets are available to be equipped of BMT-55 tooling system. The WTS has E-axis shifting function, it allows the sub spindle to move up and down to provide independent working area.

The WTS-52Y2M provide ∅51mm maximum bar feeding dia. and it can install fixed tailstock above the sub spindle when using collet, it allows to keep the longer workpiece dynamic balance with the main spindle and improves precision during machining. The WTS-65Y2M bar capacity up to ∅65mm, the A-6 spindle nose can install larger size chuck and the spindle motor upgrade to higher torque and bigger power.