Theme

Digital Transformation

Green Transformation

APACER TECHNOLOGY INC.

Product Description :

一機可檢測十種藥瓶樣式,使用新式旋轉夾具,全自動檢測無須更換治具;搭配多角度鏡頭360度拍攝,精準取像並加速檢測。雙中控台顯示與分料口設計,In-line方式配合產線進出料動線;結合自主研發AOI檢測軟體快速辨別並標示藥瓶的不良區,協助品管人員驗證更增進作業效率。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

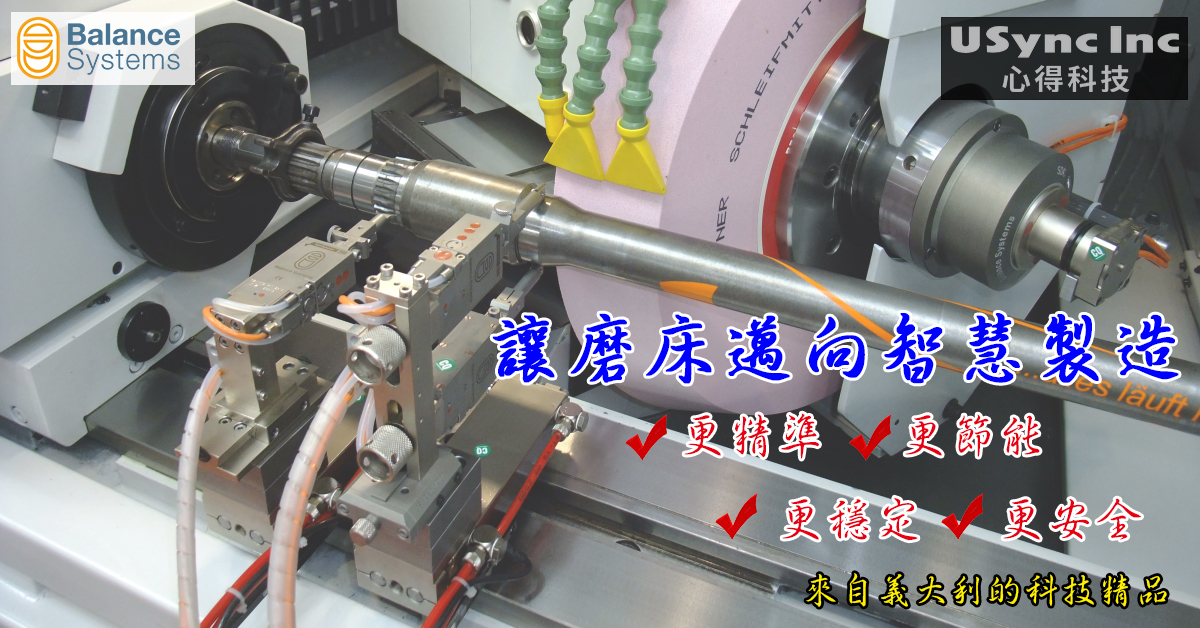

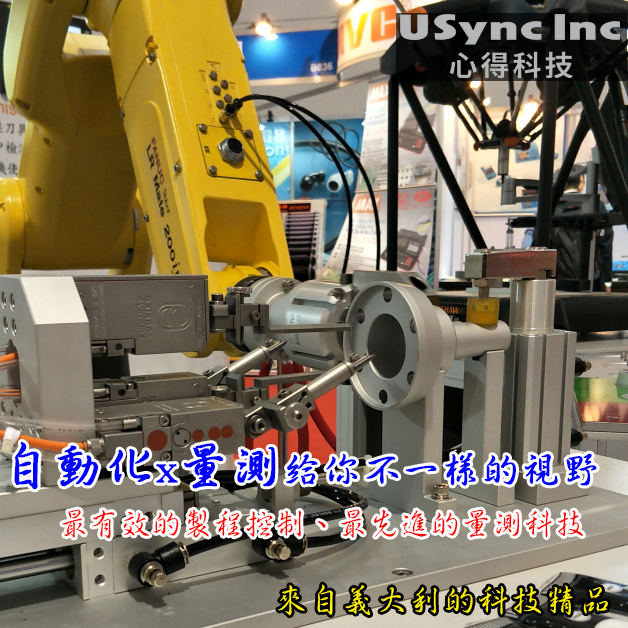

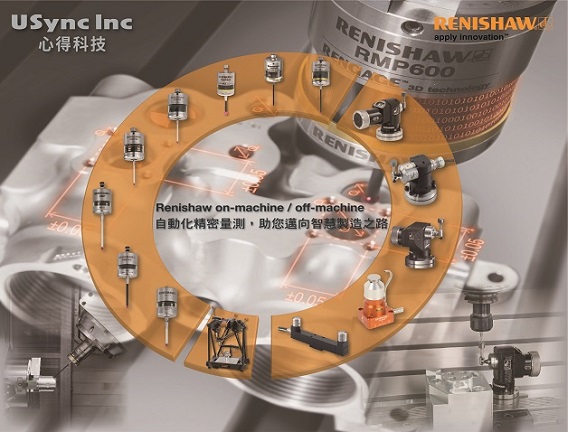

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

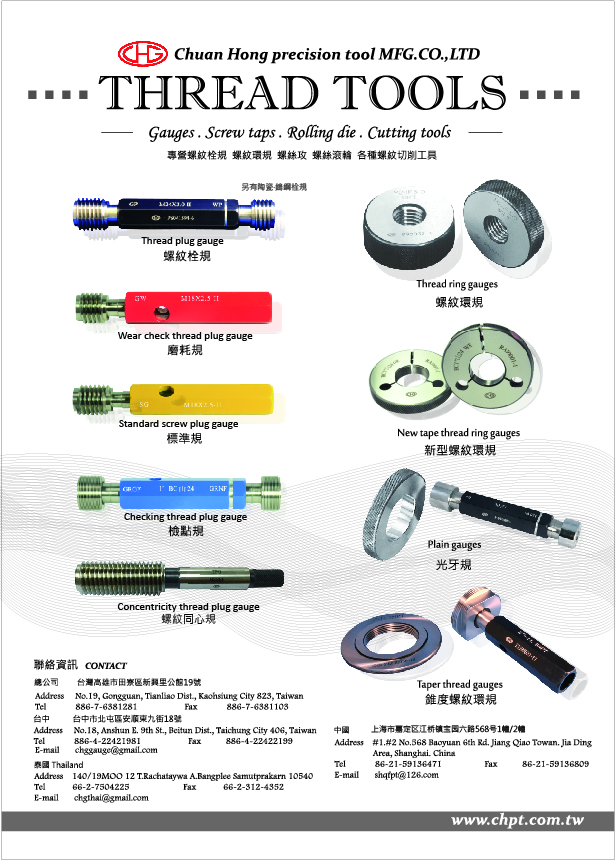

CHUAN HONG PRECISION TOOL MFG. CO., LTD.

Product Description :

<<栓規‧螺紋栓規>>

"栓規":專門檢查產品是否符合標準之量規。

"螺紋栓規":專門量測產品(母螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。

<<環規‧螺紋環規>>

"環規":專門檢查產品是否符合標準之量規。

"螺紋環規":專門量測產品(公螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。

TAIWAN INSTRUMENT CO., LTD.

Product Description :

Nikon MM-400N 高精度工具顯微鏡,搭載鑄鐵合金機身及載物台及0.1um光學尺,可量測XYZ尺寸,並且可選配高度對焦輔助器,主要在量測半導體打線及晶片,有最佳口碑及業界第一名的市占率,採用 Focusing Aid (對焦輔助) 可有效降低人為的測定誤差,提升量測精度,除維持粗調和微調的設計外,新增Z軸防落摔擋塊,避免人員因誤操作而造成機台或樣品撞擊,同時縮減機台縱深 30mm,空間的使用更彈性,平均使用年限超過二十年,可選搭鹵素燈或LED燈及各式廣角或鼻輪式高倍鏡頭,並可擴充2.5D影像量測軟體,亦可量測平面度,是品管最佳利器,主要應用在各大電子、精密模具加工廠及探針卡、電路板廠等

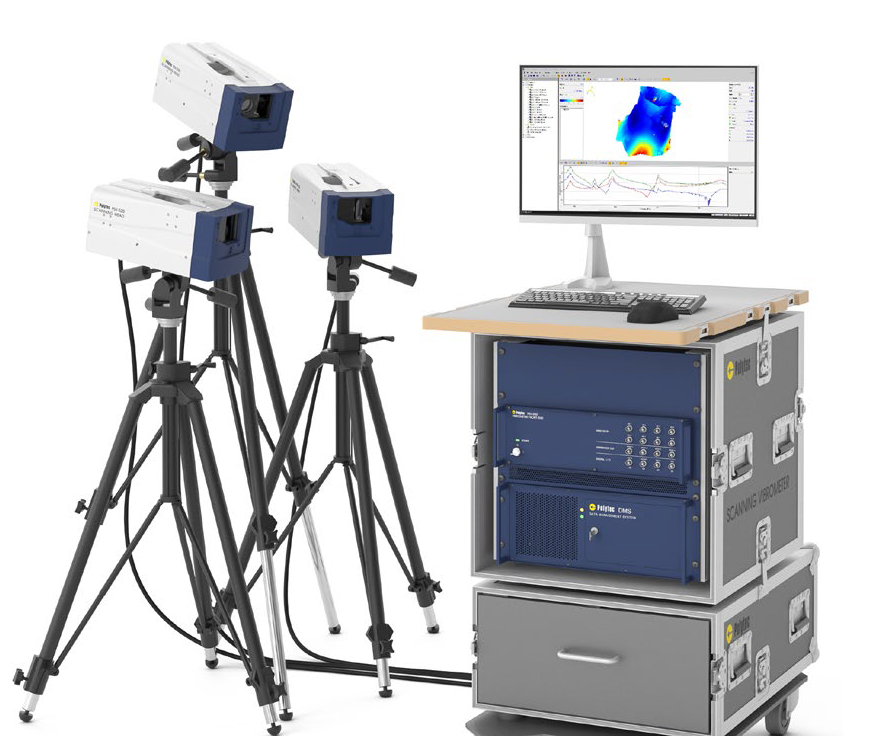

Taiwan Auto-Design Co.

Product Description :

Polytec 3D Scanning Vibrometers are state-of-the-art

for noise and vibration measurement in research and

development. Using three independent scanning

heads they deliver the full information on all vibrational

directions. The PSV-500-3D determines operational

deflection shapes and Eigenmodes for NVH, acoustics,

structural dynamics, ultrasonics, and FEM validation.

The high frequency version up to 25 MHz extends the

application range to non-destructive evaluation (NDE)

research. Every PSV-500-3D integrates perfectly into the CAE world providing interfaces to 3D geometries,

modal analysis and automation. The scanning heads

based on helium-neon laser allow measurements

even on tiny structures due to their especially small

laser spot.

PSV Scanning Vibrometers are available as

a compact laptop version or as a practical rack-type

workstation.