Theme

Digital Transformation

Green Transformation

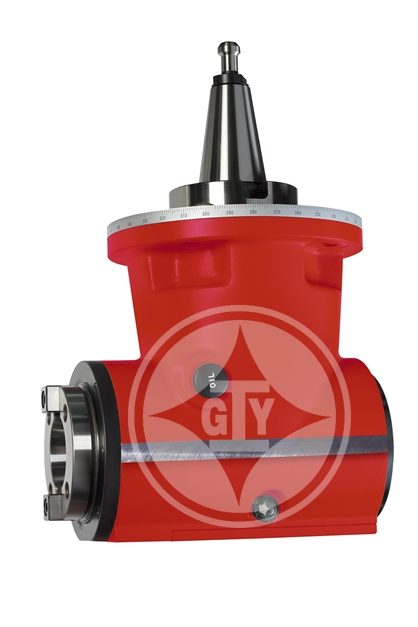

YIH KUAN ENT CO., LTD.

Product Description :

1. Semiautomatic processing angle head suitablel in all type of milling heads, can change the processing angle and also bring the powerful and high-quality cutting benefits for machine.

2.This product uses for Japanese gear grinding, so the spindle speed can up to 2000rpm and also can bring the powerful and high-quality cutting benefits for machine.

3. This product offer manual or semiautomatic two type for your optional.

4. This product offer one degree or five degree for your optional.

Tokai Spring industries, Inc.

Product Description :

Tokai spring is committed to manufacturing small-lot and custom-made spring orders because we believe that there are customers who need highly specialized, high quality spring products. Tokai spring’s mission is satisfying or even exceeding our customer’s requirements.

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

YIH KUAN ENT CO., LTD.

Product Description :

1. IK milling heads can upgrade or replacement your original machine body, milling machine or special machine.

2. Chrome quill with super precision preloaded bearing can bring the high quality cutting benifits for machine and we also offer P4 bearings for your optional.

3. Machining travel can up to 127mm (5").

4. This product offer NT30 or R8 two kind of spindle machine model for you to optional.

5. Offer table 254x1720mm、X.Y.Z travel 851x405x440mm turret milling machine body (whole body) for you to optional.

6. There are 11 models in IK Turret Milling Machine Head Series.

With ultra-precision pre-load bearings, can bring you high-quality cutting benefits, but also provide P4-class bearings for you to choose from

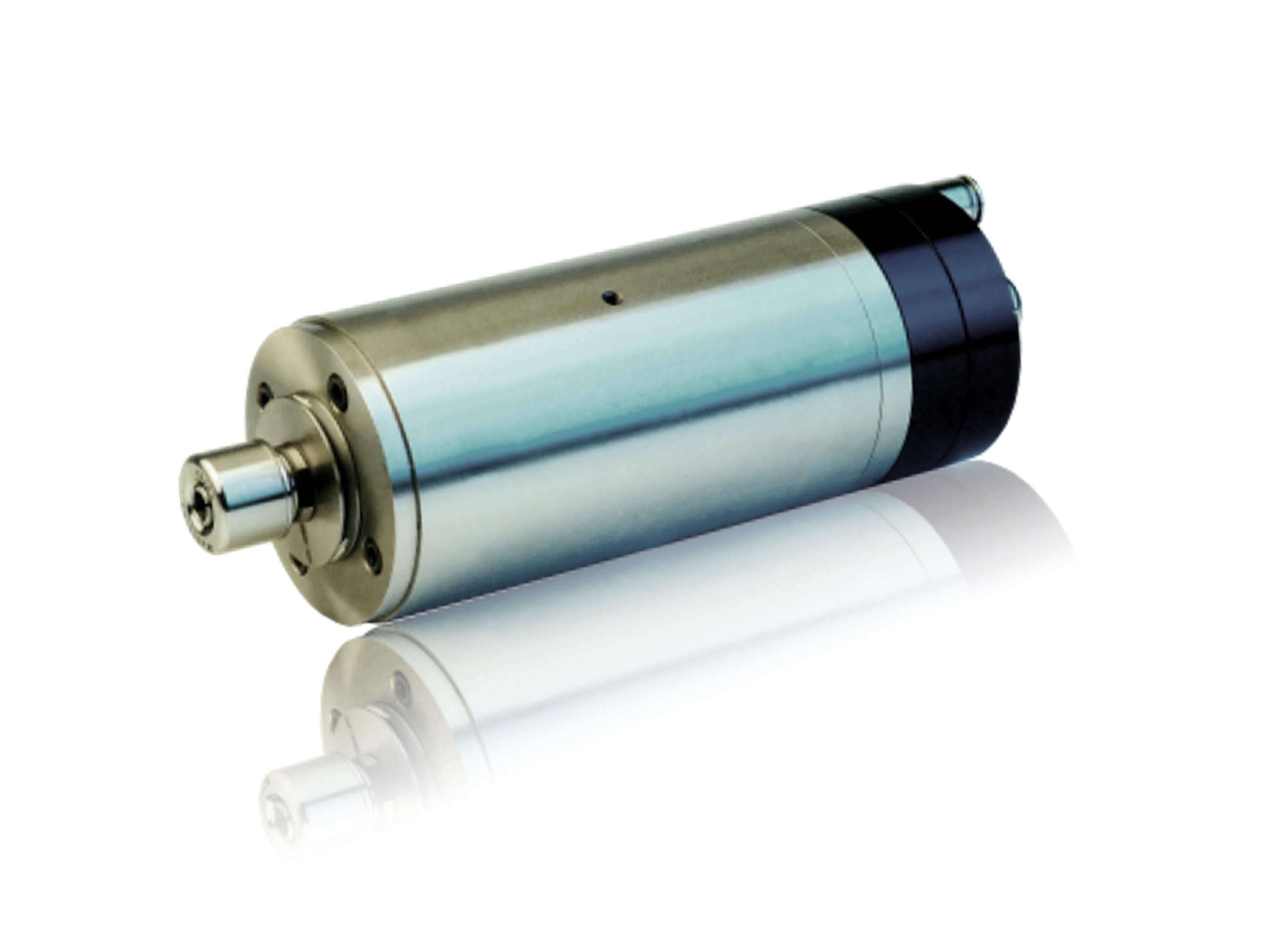

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

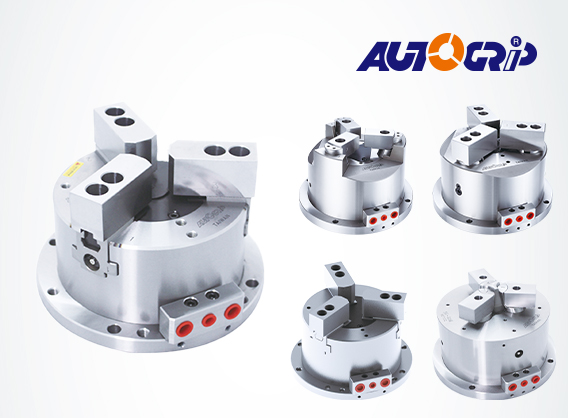

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

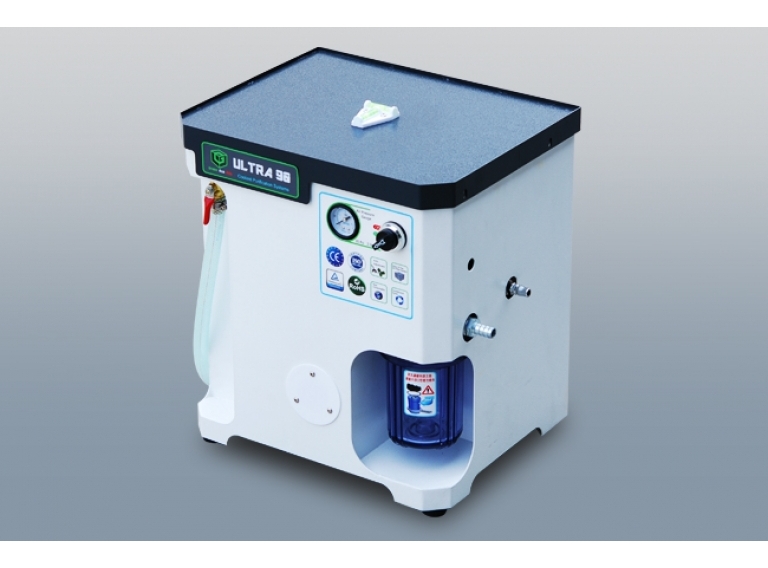

GREEN ECO PRO CO. LTD.

Product Description :

concentration on basic, To reduce floating oil on surface and prevent anaerobic bacteria and acidification of coolant. Solve the foul smell、Keep stable PH value、Save cost.

Oil reservoir capacity

Zero supplies

Patented technology - SKIMMER

Patented technology - S.T.P.M

Processing cycle

Small volume

Zero Power Consumption