Theme

Digital Transformation

Green Transformation

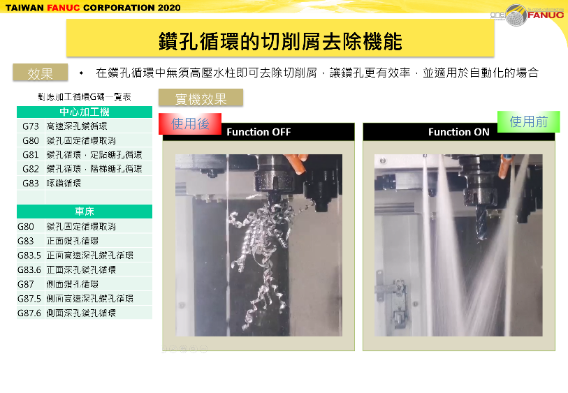

TAIWAN FANUC CORPORATION

Product Description :

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

The powerhouse in the compact CNC class

With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it comes to milling and turning on standard machines as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

SINUMERIK ONE, the digital native CNC, brings your ideas to life. SINUMERIK ONE is the leading-edge CNC system for highly productive machine tools. For unprecedented new opportunities, ideas and business models. For faster innovation based on the seamless interaction of the virtual and real worlds. What's more, SINUMERIK ONE represents much more than just a powerful hardware innovation.

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Pulse or Digital communication type

‧ EtherCAT protocol provides high flexibility of peripheral equipment connection control

‧6 path 32 axis control (max.)

‧High-speed and high-precision compensation to meet advanced turning and milling applications

‧Dual system, double feedback

‧Provide secondary development tools: HMI/PLC/Macro

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, tool wear detection...and so on

‧Applications: high-speed lathe, turning-milling complex machine, dual-system lathe, double feedback lathe, gear hobbing machine

TAIWAN FANUC CORPORATION

Product Description :

Lathe chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

Product Description :

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?

LNC TECHNOLOGY CO., LTD.

Product Description :

• 7” touch screen

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

• All-in-one design: pendant integrated with control unit

• IP65 waterproof and dustproof protection

• Magnetic back fixing bracket

• Electronic hand-wheel design to machine tuning, facilitate adjustment and program dry run

• Support multiple types of robots: Six-axis, Delta SCARA or customized special type robots.

• Axis control: six-axis(for robot itself) and additional three axes (for external accessories)

• Application: Polishing robot, spraying robot, welding robot, handling/palletizing robot

TAIWAN FANUC CORPORATION

Product Description :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Pulse or Digital communication type

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

•High-performance motion control technology

-High-speed and high-precision processing

-Real-time PLC for better accurate and stable control of peripherals

•Applications: Processing center, Tapping machine, Engraving machine, Polishing machine, Double-head milling machine, aluminum profile machine, five-axis milling machine...etc

•Secondary development tools: PLC/Macro/HMI

•Auxiliary function

- File protection function

- Online help function

- G/M code synchronous query function

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, broken tool detection…etc.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

TNC7

Innovative | Sustainable | Reliable

Continuously developed, the new software version 18 of the TNC7 fulfills many requests from users and machine manufacturers about ease of operation, reliable processes and enhanced functions.

Discover intelligent functions with which the TNC7 can assist you in your future tasks!

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Provide control and development flexibility, quickly upgrade equipment to smart machines

‧Fourth/fifth-axis control ;provide up to 32-axis control via EtherCAT protocol

‧Optional RFID function for personnel authority and data control

‧Optional robot control function module, integrated robot control with tool machine to complete automation processing.

‧Connect to LNC smart vibration sensor, SVI1000/2000 to develop various smart value-added functions

‧Connect with video devices to develop image-related application functions, such as processing monitoring or positioning.