展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

NUMEN MACHINERY CO., LTD.

製品の説明 :

Delta 6 is designed for new dimensions in precision, contour accuracy, surface quality and productivity. Maximum dynamics, precision performance milling and HSC machining are accurately executed. Offering wide range of applications including electronic watch, optical, medical and die mold.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

製品の説明 :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

The latest crumb collection and +1um precision filtration machine. This bottom debris recovery filter is equipped with a 1.5-inch large suction pump, which can quickly collect and dry the bottom debris and sediment in the water tank, allowing customers to clean it conveniently. This machine is equipped with a multi-functional stainless steel filter barrel that can collect coarse bottom debris. At the same time, using our patented technology, there is no need to replace the filter barrel, and it can continuously perform precision filtration up to 1um, thereby intercepting and filtering impurities and suspended particles in the water.

DYNA COMPRESSOR CO., LTD.

製品の説明 :

2 STAGE ROTARY SCREW

Powerful two stage compression performance surpasses one stage compression.

For this series of new designs, we use two-stage compression. The compression efficiency creates the most energy-efficient air compressor, keeping the flow rate, power consumption and temperature in the best condition, making the screw air compressor more energy-saving, more power-saving, and more suitable for your use. Improve your production efficiency, and also greatly save power consumption. Our design and manufacturing technique has always been being the quality guarantee.

YI CHANG MACHINERY CO., LTD.

製品の説明 :

Regardless of whether you use semi-automatic drilling machines, manual tapping & drilling machines, pneumatic machine, hydraulic machine or gear type machine, they can be assemble with multiple spindle head and servo slides to greatly enhance work efficiency while meeting diverse production needs.

This machine type combines mature semi-automatic technologies such as pneumatic, hydraulic, and gear type systems, assemble with multiple spindle head and servo slides, expanding the application range of drilling and tapping machines and making them more adaptable to various production requirements.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Grinding

* Applications|Tungsten Carbide Blade Tool Processing

1. Excellent grinding ability, significantly reducing spindle load, save processing time and cost.

2. Tough texture and wear resistance characteristics to achieve the maintenance of tool dimensional accuracy.

* Processing Material | Tungsten Carbide

LEEKA INDUSTRIAL CO., LTD.

製品の説明 :

We produce draw latches with different kinds of size and specifications.

The material uses stainless steel and Iron.

Color: black powder coated or bright chrome.

The installation depends on different type of latches: horizontal or vertical installation and can be used with padlocks.

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

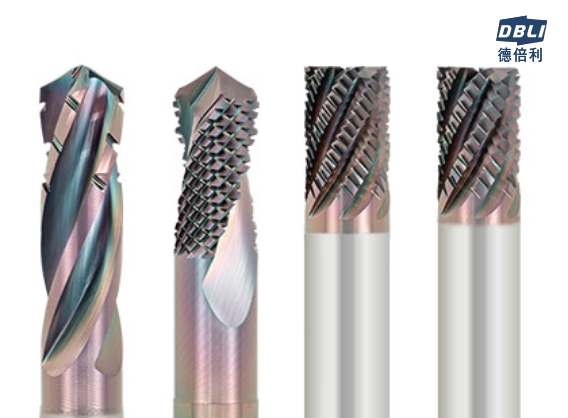

1.With excellent features of coating to increase the tool life and wear resistance performance.

2.With unique geometry to effectively remove fabric residue.

◆Cutter Speialized in Cutting Fiber End Mills:

Patented flute shape/new design.

◆Cutter Specialezed in Cutting Fiber Drills:

Excellent performance in drilling burrs and tearing.

◆ Cutter Specialized in Cutting Fiber Drill End Mills:

Suitable for thru hole machining.

KAO MING MACHINERY INDUSTRIAL CO., LTD.

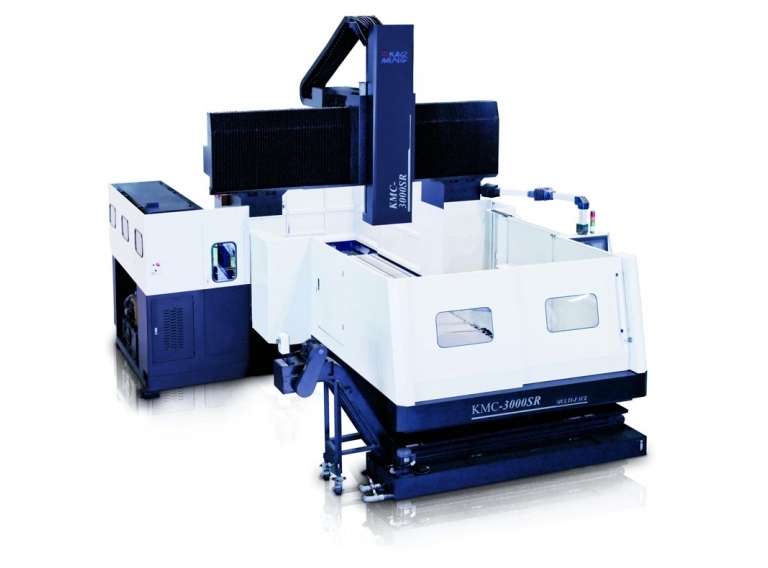

製品の説明 :

1. 三軸採用方形硬軌設計,滑動件為全行程支撐,無懸伸下垂之問題,結構剛強適合重切削。<br />

<br />

2. 門寬2.1米以下,底座採用雙軌設計;門寬2.3米以上,底座採用四軌之滑動與滾動複合化設計。<br />

<br />

3. Y軸橫樑為階梯之軌道設計,段差70mm確保加工精度與穩定性。<br />

<br />

4. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

5. Y、Z軸滾珠導螺桿之安裝,其頭座與尾座係與橫樑及床鞍鑄成一體,確保最大剛性及精度。<br />

<br />

6. 機械式扭力限制器安全裝置,可避免機器在受到意外碰撞或操作錯誤時,重要機件不會因此被破壞。<br />

<br />

7. 刀庫為油壓分度馬達傳動;換刀臂之旋轉為油壓搖擺馬達驅動,確保ATC換到系統之快速、精確及穩定性。<br />

<br />

8. X軸8米以上四軌床身為線性導軌傳動,中央為主支撐兩側為滾子式履帶軸承輔助支撐,以增加傳動效率。<br />